BSM-50 Electric Motor stator Cutting Machine

Simple design and powerful functions are combined in BSM-50, this machine is specially designed for cutting electric motor stators and motor cases, durable and high troque. The shape and material of its blades are carefully designed and selected by us to perfectly complete the cutting task. Small in size and easy to operate make it the best choice for all customers.

features of Electric Motor stator Cutting Machine BSM-50

Electric Motor stator Cutting Machine BSM-50 from BSGH Granulator is designed to cut your scrap motors, its cutting part is made up of a flat and sharp blade. By combining casing removal and stator cutting in one powerful unit, our BSM-50 allows recyclers worldwide to process the entire motor efficiently.

- Control levers adjust the blade movement, precise and visible.

- Handle shell of waste motor below 500mm under 50KW, larger than normal metal motor stator cutting machine.

- Customizable Size, voltage and color

- Popular combination plan:

+ BSM-40 Scrap Motor Recycling Machine

More needs, check Electric Motor Recycling Machine for reference.

best Electric Motor stator Cutting Machine BSM-50 for sale

Due to the configuration of a larger blade than the same series of scrap motor recycling machines, the BSM-50 scrap motor cutting machine can separate larger shelled motors, allowing you to obtain more copper windings effectively. Please check the detailed parameters and raw material pictures below:

| Model | Electric Motor stator Cutting Machine BSM-50 |

| Power | 7.5KW |

| Range | Stator Diameter 50-500MM |

| Maximum Operating Current | Approximately 17A |

| Hydraulic Oil | 40KG |

| Pressure | About 20MPa/30T |

| Cutting Parts Weight | 530KG |

| Power Units Weight | 120KG |

| Cutting Parts Size | L750*W550*H2150 |

| Power Units Size | L90*W48*H65 |

Video description

Machine model: BSM-50 Electric Motor Cutting Machine

Customer place: USA

Purchase time: 2020

Raw material: all kinds of scrap motors and stators

The customer also bought a BSM-40 Electric Motor Recycler, Both BSM-40 and BSM-50 are always work together to achieve recycling aim. BSM-50 is designed to break the motor shell and cut the stator in half. BSM-40 is used to pull out the copper winding on the stator. Excellent cutting ability makes the operation smooth and stable receiving customers’ 100% satisfaction.

Premium Blades & High-Torque Power System

BSGH Granulator Electric Motor stator Cutting Machine BSM-50’s extensibility is impressive. Users often purchase it as a powerful waste motor cutting tool, at the same time pairing it with BSM-40 to accomplish perfect and efficient cutting and pulling tasks for waste motors.

Besides, we will supply customers with a higher-power enlarged motor to drive the machine’s cutting part, both improving your recycling efficiency and ensuring powerful machine operation.

Attention: There are two running tracks on both sides of the cutter, which need to be refueled daily, and it’s best to add lubricant more than twice a day.

100% Copper Motor

BSM-50 is powered by a pure copper and enlarged motor that drives the hydraulic system with consistent force.

Dual-Blade Cutting System

The Flat Blade: Used to cut motor outer casings forged from high-wear resistant alloy steel to prevent breaking.

The Sharp Blade: Used to cut motor stator into half and undergoes heat-treated to prevent rust & corrosion.

Electric Motor stator Cutting Machine Advantages

The machine is equipped with two kinds of blades. Flat blade is used to crush motor shell. Sharp blade is used to cut stator.

It can process motor with a diameter less than 500MM.

It occupies a small area and is also easy to operate. The use requirements of BSM-50 are simple so it is suitable for everyone.

Reliable material: Two blades use different materials depending on their work feature. Sharp blade is made of H13 steel which has good wear resistance and toughness. Flat blade is made of No.45 carbon steel which has good resistance to deformation.

shipment

Once we confirm the order, the production will be started immediately. Before arranging shipment, we will send you a machine testing video to ensure that you receive a intact and functioning machine.

Why Choose us?

As we have always done, Excelsior is our consistent purpose, and BSGH has always strived to become the world’s leading copper recycling machine manufacturer and one-stop scrap metal recycling solution provider.

In general, what our machines can do? If you hold plenty of scrap wires, motors, radiators, or other waste metal products, then our machine could turn these wastes into treasures. we provide a wide range of customization plans for many kinds of machines to uplift your recycling efficiency. So you don’t have to worry at all about our machine’s name not living up to its reputation, owning them will only make you increasingly wealthy.

In detail, our BSM-Series Scrap Motor Recycling Machines can process almost all motors with stator outer diameters less than 500 mm. For example, DC motors, vehicle motors, household appliance motors, compressor motor, and other industrial motors are all easy to process for these professional machines.

If you have any further questions, don’t hesitate to contact us. Our professional sales team and engineers will be dedicated to serving you wholeheartedly!

Good feedback from global clients

Customer satisfaction is our constant motivation. These customers come from all over the world, and they have enabled our machines to release tremendous economic value. Let’s take a look at their feedback together.

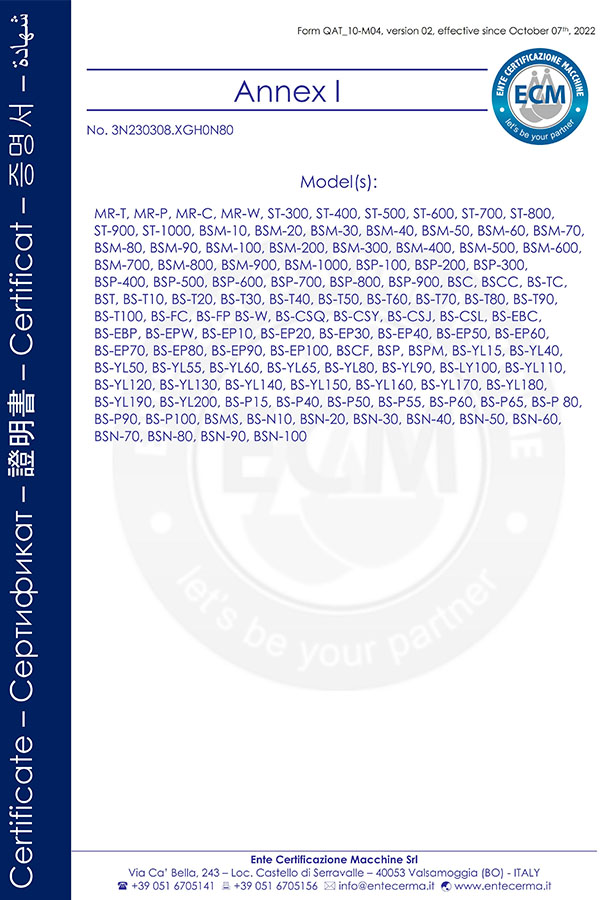

CE for Electric Motor stator Cutting Machine

FAQ

How should I measure my motor?

You should measure the outer diameter of your motors. Our BSM-50 Motor Cutting Machine can handle motors with an outer diameter of less than 500mm.

Why is the Electric Motor stator Cutting Machine equipped with two different blades?

To achieve optimal results, we specifically designed two types of blades. The flat blade is specifically designed to cut through the hard motor housing, while the sharp blade is used to cut copper winding or halve the stator for easier subsequent pulling.

Can the Electric Motor Stator Cutting Machine BSM-50 cut compressor casings?

No, the BSM-50 is primarily for common motors. For compressors with robust casings, we offer specialized plasma cutters and Blades Compressor Cutting Machines.

is the Electric Motor Stator Cutting Machine easy to maintain?

Yes, our Electric Motor stator Cutting Machine BSM-50 is easy to maintain, you just need to add oil to the hydraulic tank regularly and replace blade when dull.