Cable grinder machine manufacturer and supplier

The cable grinder machine is a series of machines launched by BSGH Granulator after years of research, practice and technological innovation. With one-time feeding and intelligent automatic production progress, our machines effectively separate and recycle copper and plastic in the cable shredding process. The emergence of cable grinder machines solves the problems in the incineration copper extraction method, improves the quality of recycled copper, and solves environmental pollution at the same time.

- BSGHGranulator cable grinder machine has complete specifications, we provide you with 60+ types of copper rice machines.

- Our machine ispowerful, stable in operation, and energy-saving, helping you reduce costs.

- Our machine is equipped with an electrostatic separator to reduce copper loss and increase recovery rate

- The dust collectionsystem operates continuously to avoid pollution during machine production.

- One-time feeding, multiple machines coordinate, only one workercan complete the whole process.

BUY Cable grinder machine with confidence

BSGH Granulator has a history of more than 25 years of experience in the industry for manufacturing of cable grinder machines. We use the highest quality steel and fine craftsmanship to ensure that our products are durable and beautiful. We pay great attention to product details to ensure that each machine is well-produced and of the highest quality. Our Cable Grinder Machines are directly supplied by the manufacturer, ensuring rapid shipping and reliable delivery with quality. These machines have gained widespread popularity in the United States, Canada, Spain, and many other countries.

choose your cable grinder machine

Model | Capacity(kg/h) | Weight(KG) | Power(KW) | Dimension(MM) |

1200~1500 | 18000 | 120 | L15500*W9500*H2500 | |

1000~1200 | 8700 | 98 | L10000*W9500*H2200 | |

800~1000 | 5800 | 76 | 7200*7500*2200 | |

400~700 | 5000 | 67 | 12000*3500*2250 | |

300~500 | 3200 | 40.5 | 3900*2000*2250 |

what configurations of cable grinder machine we can do?

BSGH Granulator offers various configurations for the Cable Grinder Machine to meet diverse customer needs and operational requirements. Here are some possible configurations, some are must and some are optional.

the must part

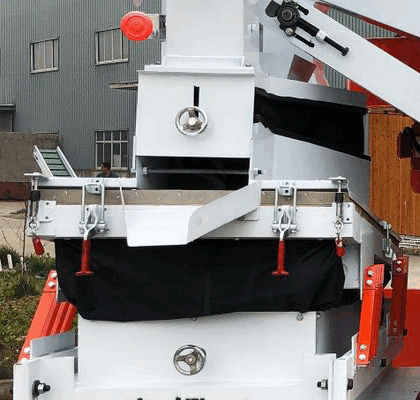

air separator bed

Aire separator bed is very important for cable grinder machine, this part is the separates metal from insulation using vibration and airflow

Main Crusher

The Main Crusher is a critical component of the Cable Grinder Machine, designed for fine crushing of scrap cables and wires. Its primary function is to reduce the size of the cables, preparing them for separation.

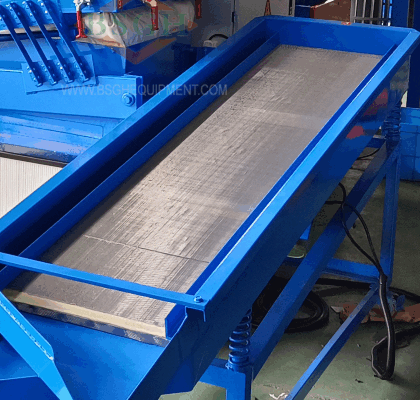

small table vibrator

This machine is very necessary for copper separation, the main function is for secondary separation assemble with air separator system.

optional configurations

Normally customers they are have all kinds of scrap cable types, some times when you talk with us, we will ask some related questions, that’s because we know more about your cable wire conditions then we can recommend you the proper configurations to let your cable grinder machine reach the best effect. Different configurations have different functions, detail as below.

electrostatic separator

The Electrostatic Separator is a crucial component in cable recycling, particularly for thin scrap cables, achieving the highest purity in metal copper and plastic separation.

Double layer magnetic separator

There are 3 kinds of magnetic separators in total. Double layer, belt magnetic separator and strong magnetic separator are what we designed and invented many years ago, If your cables have metal, then you must buy this machine in order to let your copper be 100% pure.

pre-shredder

Various shredder for options.

For big-volume customers, a pre-shredder is must before cable grinder machine, Its primary function is to reduce the size of the cables, preparing them for further granulation and separation, thus improving recycling efficiency.

BSGH Granulator -Your most reliable partner

Your ultimate solution for efficient, eco-friendly cable recycling equipment – best cable grinder machine in China

Come and Enjoy an AR journey to BSGH ➜

Customer feedback

You can feel how happy they are, you will be the same happy with them after you use our cable grinder machine; choose us your money and your machine is all safe, I trust you will be very satisfied with our machine. Give us an opportunity, we will create a better future together.

Why choose us?

Our company is the really professional factory for producing cable grinder machine since 1995.

At present, there have large number of cable wire grinder machines in the recycling industry, and the quality is uneven. As an industry leader, BSGH Granulator company always pays attention to the rapidly changing consumer needs and continuously upgrades and updates our machines. We have 3 major advantages:

- Quality control: We guarantee that every machine we sell is made of new qualitative materials and we strictly control its quality according to the highest standards. This makes our machine more durable and lasts longer than 99% of similar machines.

- Price control: We keep the price to the lowest while ensuring high quality. Our machines are shipped directly from the factory, without middlemen to make a profit, minimizing your costs.

- Service control: We provide you with a very comprehensive one-stop service, including but not limited to: One-to-one model recommendation, customization service, installation service, operator training, and answers to questions about machine use. If you have any questions about our machines, you can contact us and we have professional staff to answer your questions.

Multi choice | One stop solutions

get a free quote now!

- Pre-sales service:

- Help customers choose the right model of equipment.

- Design and manufacture products according to customers’ special requirements

- Sales service:

Inspection of machine quality during production.

- After-sales service:

- Equipment installation and debugging.

- Answer any questions you may have while using the machine

This form will allow you to send a secure email to BSGH Granulator.