BSGHVehicle Car Starter recycling Machine

Inventor | Specialty | Multifunction | Sole in the World – More than 10 Years Selling Experience

Car Starter Recycling Machine manufacturer

Our car starter recycling machine can handle car starters from various scrap cars. It consists of four machines, each perform their own duties and also cooperate with each other. The setting of each part of the workflow has been carefully considered by the technicians in advance and also proved in the market using. Reasonable design leads to high work efficiency, good material ensure the durability, advanced technology contributes to the high quality of final product.

1. The material of alloy manganese steel which is sharp and durable

2. Four machines coordinate to work to reach the best recycling effect and the highest recycling efficiency.

3. Easy to operate saving money on manual training.

4. Hardening treatment increases the lifespan and durability of the machine.

principle & Structure

The structure of auto motor starter is special and it’s difficulty for recycling.

We designed 4 processes to break through the recycling difficulties one by one. The machine combines four steps of cutting, pressing, heating and pulling to recycle motor completely. Actually, these four steps represent four different machines. You can learn about their details through the following Tabs.

The cutting part is mainly used to cut off the copper winding head in the starter. The blades in this part are made of alloy manganese steel which is a kind of wear-resistant material and we also adopt hardened treatment to it thus making the blade pretty sharp. The capacity of the oil cylinder is large enough, so its cutting force is strong.

This part consists of a press head and an iron base needed when you process, it’s a small hydraulic pressing machine, but it’s huge pressure is generated to press the copper head.

This structure of the heating coil is made of high temperature resistant material.

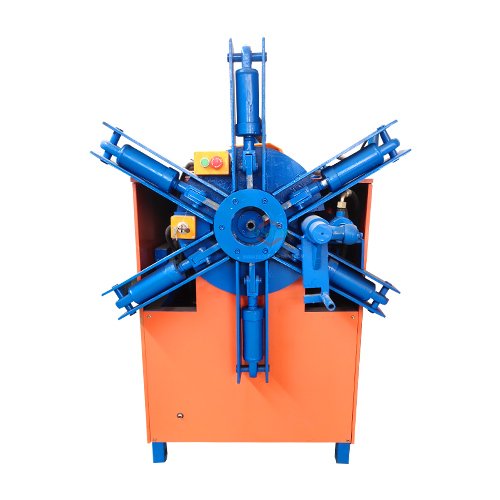

The hydraulic system with 6 pressure heads controlled by 6 chucks aims to firmly grasp the starter, and then use the hand control to pull out the rotors, then rotor and copper winding will be separated.

car starter recycling machine Working process

Steps 1: The worker must place one end of the starter beneath the blade of the motor cutting machine. After each cut, the starter should be rotated until the copper winding can be fully cut.

Step 2: This step is manually operated. One hand of the worker controls the speed and degree of the pressure head through the operating handle. The other hand is used to control the direction and angle of the starter. In this way, it can be pressed accurately, and the effect is wonderful.

Step 3: The operator should use pliers to place the starter in the heating coil. After heating is achieved, use pliers to take it out. Heating is crucial for two reasons. The first is that some starters have injected glue in them, so heating can prevent the glue from sticking to the motor. The second reason is some copper wires are very thick. Heating can soften the copper wires very well and facilitate subsequent separation.

Step 4: Place the heated starter in the car starter pulling machine, and the six chucks will hold the motor tightly, then the copper winding and the starter can be separated smoothly.

Please refer to the operation process demonstration video below.

Playlist

1:21

0:59

0:44

0:19

Our Service

Pre-sale

Tell us about your motor recycling need

deal Confirmed

After the transaction is completed, we will contact the manufacturer as soon as possible to arrange the production of the machine and send you a video of machine’s operation for you to check making sure it can operate normally.

After-sale

Our services do not stop here. When you encounter problems during operation, please contact us at any time and we will answer you fast online. For questions that cannot be answered online, also no need to worry, we have a strong technical team and considerate services for you.

Meanwhile, we don’t just stop at online support. If you have problems that can’t be resolved remotely, our technical staff will come to your country to assist you, wherever you are. You can count on us to go the extra mile to ensure your satisfaction.

In fact, we as more than just a supplier – we’re your best partner in success. With our perseverance to excellence and unwavering support, you can trust us to help you achieve your business goals.

The Potential of Auto Starter Motor Recycling Machine

With the advancement of science and technology and the improvement of people’s living standards, the scope of using cars is becoming wider and wider. At the same time, the world’s demand for metals is also increasing, the demands for metals exceeds its supply. Driven by these two trends, the auto starter recycling market emerged as the time requires. We follow the pace of world development and are committed to developing auto starter recycling machines with high recycling efficiency and good quality.

If you have more scrap motors like vehicle generator motors, DC motors, household appliance motors, compressor motor, and other industrial motors, please contact us, our professional sales team will customize unique recycling plan to satisfy your need. Or you can see Scrap Metal Recycling Market Analysis to learn more about this market.

I believe a good recycling machine allow you to gain great profits and also do your part to protect the environment.

Welcome to Cooperate with Us

We have a professional technical team for car starter recycling machine R&D, with rich experience and strong professional skills, tirelessly innovating machines, so we not only have recycling machines for car starters but also for many other waste metals and devices. They are equally good and can be your right-hand man. We look forward to cooperating with you!