Heavy-duty container shear machine for cutting scrap metal

Easily shear tough scrap metals with BSGH Granulator heavy-duty container shear machines. Built for high-performance cutting, they effortlessly handle a wide range of hard materials. Featuring powerful hydraulic systems and intelligent PLC controls, these machines are designed for continuous cutting in demanding industrial condition.

Reliable container shear machine for sale

Tackle the toughest scrap with confidence. Our container shear machine is your ultimate solution for cutting large, heavy, and irregular metal materials—fast and effortlessly. From thick steel plates to worn-out beams and scrap metal, it delivers clean, consistent cuts every time.

High Shearing Power – Easily slices through dense materials with industrial-grade force

Premium Blades(60si2crV) – Engineered for durability and long-lasting performance

Versatile Applications – Ideal for steel processing, recycling, and demolition

Compact & Portable – Fits in containers, making it perfect for on-site operations

Boost your productivity and cut through anything—reliably, efficiently, and safely.

Note: We also support customizing the diesel-driven container shear machine for you if you haven’t electricity in your factory.

Explore the BSGH Container Shear Series

We offer our horizontal shear machine in four powerful models, each designed to meet different cutting capacity needs. With varying shear forces and tonnage levels, you can choose the ideal machine based on the type and volume of metal you process. Whether you’re handling light to medium scrap or dealing with heavy-duty industrial materials, there’s a model to match your operational demands—ensuring maximum efficiency, safety, and durability.

CS-4000 Container Shear

Don’t let its size fool you — the CS-4000, the smallest model in BSGH Granulator’s container shear series, delivers serious performance. Equipped with dual cutting cylinders, it generates an impressive shearing force of up to 4022 kN, easily handling a wide range of scrap metal with power and precision.

Key Specifications:

- Cutting Force: 4022 kN

- Hydraulic System Pressure: 25 MPa

- Blade Length: 1400 mm

- Press Box Dimensions: 2400 × 1400 × 1882 mm

- Total Power: 74 kW

Compact yet robust, the CS-4000 is the perfect solution for scrap yards, recycling centers, and metal processors seeking high performance in a space-saving design.

CS-5000 Container Shear

The CS-5000 strikes the perfect balance between performance and affordability. With an intelligent PLC control system and remote operation capability, the CS-5000 improves efficiency and ease of use in your operation. If you’re looking for maximum return on investment, it’s the machine to beat.

Key Specifications:

- Cutting Force: 5000 kN

- Hydraulic System Pressure: 21.5 MPa

- Blade Length: 1400 mm

- Press Box Dimensions: 2400 × 1400 × 1882 mm

- Processing Capacity: 8–10 T/H

- Total Power: 160 kW

- Control System: PLC + Remote Control

Built for demanding jobs, priced for smart buyers.

CS-6300 Container Shear

The CS-6300 is built to take on heavier and harder scrap materials with ease. With an upgraded blade length of 1600 mm and a larger press box, the CS-6300 is engineered for operations that demand greater throughput and reliability, consistently processing up to 10 tons per hour.

Key Specifications:

- Cutting Force: 6284 kN

- Hydraulic System Pressure: 25 MPa

- Blade Length: 1600 mm

- Press Box Dimensions: 2400 × 1600 × 2132 mm

- Processing Capacity: 10 T/H

- Total Power: 160 kW

- Control System: PLC + Remote Control (optional)

When strength, stability, and efficiency matter most, the CS-6300 delivers.

CS-8000 Container Shear

As the largest and most powerful model in the BSGH container shear series, the CS-8000 is purpose-built for heavy-duty, high-volume metal processing. Delivering an impressive 8000 kN cutting force, it’s engineered to handle the most demanding shearing tasks—from oversized scrap to high-density materials.

Key Specifications:

- Cutting Force: 8000 kN

- Hydraulic System Pressure: 25 MPa

- Blade Length: 1600 mm

- Press Box Dimensions: 2667 × 1600 × 2080 mm

- Feeding Opening Size: 3400 × 2400 × 900 mm

- Total Power: 165 kW

If you’re handling large-scale scrap and need maximum productivity, CS-8000 is the ultimate shearing solution—delivering power, durability, and efficiency in one rugged machine.

How to maintain the container shear machine?

1. Please remove the garbage and oil stains from all parts every week.

2. Clean the oil inlet filter once a month. If it is damaged, replace it in time.

3. Maintain the blade once every 3 days, tighten the blade bolts to prevent the blade bolts from loosening.

4. Check and tighten all bolts every week.

5. Check the quality of the hydraulic oil frequently. If abnormalities are found, replace the hydraulic oil in time and clean the oil tank. Clean the oil tank at least once a year.

6. The oil inlet filter or the oil return filter should be replaced regularly every 3 months.

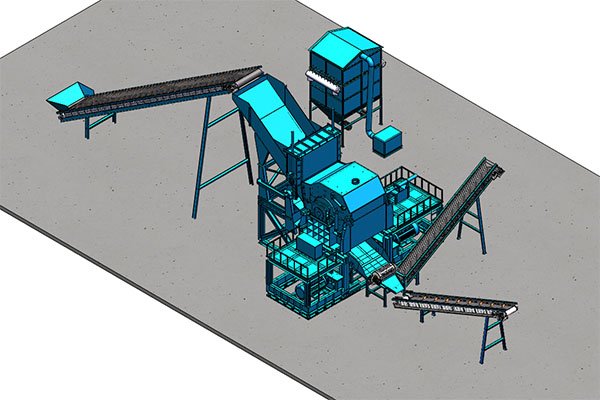

metal shredding line

find in the site

hydraulic container shear machine advantages

Powerful Shearing Force

Strong shearing force, capable of pressing and shearing various materials that are difficult to handle, such as steel bars, steel plates, metal beams, etc., at one time.

excellent hydraulic system

Equipped with a reliable hydraulic system, our container shear machine provides smooth and consistent cutting force and supports flexible adjustment of working pressure.

low noise

Adopt a closed material box, low noise and vibration during operation, create a more comfortable working environment for your team.

good quality blades

Durable cutting blades are engineered to resist wear, reducing replacement frequency and long-term costs.

easy to operate

Intuitive PLC control system, easy to operate. One operator can run the machine, and even a novice can quickly get started.

How does our container shear work?

This video show our hydraulic container shear machine in action as it processes scrap steel. A material handler feeds the scrap into the container shear, which cuts and compacts the material into smaller, more manageable sizes. The entire process is efficient, streamlined, and ideal for high-volume metal recycling operations.

What industries does our container shear machine serve?

Our machines are designed for processing heavy industrial waste and are widely used in the following fields to efficiently cut thick and heavy metal components, significantly reduce transportation and smelting costs, and maximize the value of waste.

Metal recycling industry

Cut various types of metal scrap, such as scrap steel, aluminum alloy, copper, etc., to facilitate subsequent transportation, smelting, and reuse.

Steel mills and metal processing plants

Process scraps, defective steel, scrap steel billets, etc. generated during the production process to achieve secondary utilization of raw materials.

Scrapped car recycling and dismantling

Cut heavy parts such as body beams and engine casings.

Shipyards and ship dismantling

Cut thick and strong hull steel plates, keels, metal pipes, and other components.

Construction industry

Separate steel bars, metal brackets, etc., from construction waste and recycle them as scrap metal after cutting.

Steel structure manufacturing and dismantling

Cut engineering waste (H-shaped steel, steel plate beams) to greatly reduce the transportation fees.

Usage Guidance

Precautions before starting

Check whether there is enough oil in the lubrication gear pump.

Check whether the hydraulic oil in the hydraulic oil tank is normal.

Check whether the cylinder connection bolts are loose.

Check each pipeline for oil leakage.

Check whether there are foreign objects in the material box.

Check whether the blade is normal.

Precautions before feeding

After starting, let the container shear machine run for a few minutes without load to see if it is normal.

Check each pipeline for oil leakage. If so, stop immediately.

Check whether the circuit connection is normal.

Notes during operation

Do not feed too much at one time.

Do not feed inflammable and explosive items.

The operator cannot clean the material box while the machine is working.

The operator must not get too close to the machine. If there is any abnormality, press the emergency stop immediately.

The operator must not leave the work site during operation.