copper chopper machine

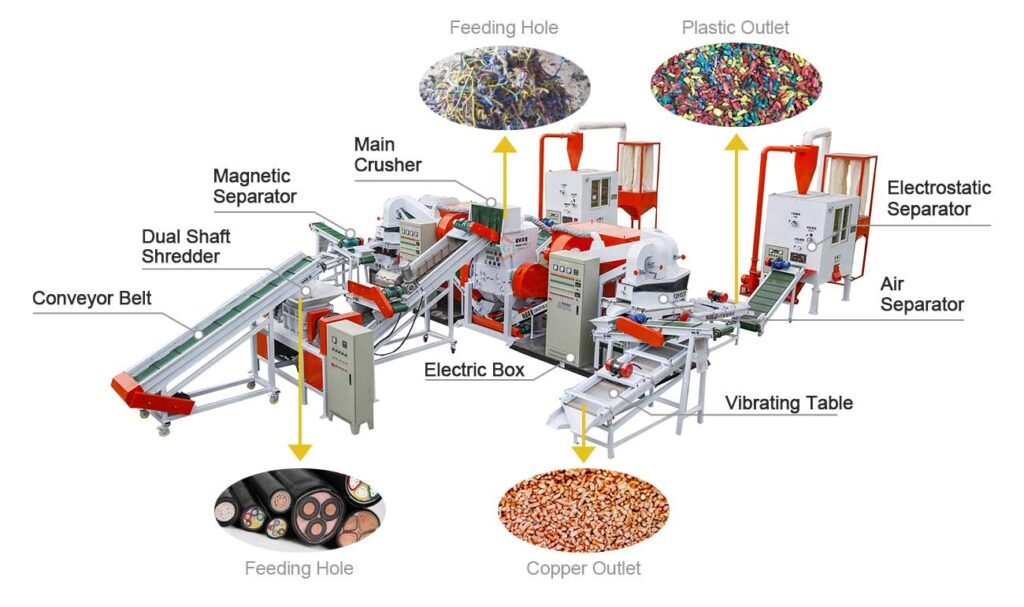

The copper chopper machine from BSGH Granulator is engineered for precision and well performance, providing a comprehensive solution for copper wire and cable recycling. This machine is adept at shredding waste wires and efficiently separating copper from its insulation covering at a fast speed and resulting in high-purity copper granules. It is constructed with a focus on operational longevity and reliability, incorporating features that facilitate the use of machine and less requirement of maintenance.

Its advanced design minimizes downtime and ensures a smooth operational flow, enhancing productivity. With BSGH’s expertise in recycling technologies, this copper chopper machine represents a sophisticated approach to recycling, designed to meet the specific needs of the industry with precision and efficiency.

Our copper wire granulator Machines

We Provide high quality copper chopper machine

Our copper chopper machine is built with outstanding performance in mind, providing a dependable and effective option for processing a wide range of copper wires and cables. It is outfitted with cutting-edge technology to enable efficient separation and recovery of high-purity copper granules. This machine is rigorously developed for durability and ease of use, reducing downtime and increasing output. Our copper chopper machine, with an emphasis on accuracy and quality, delivers an extraordinary return on investment, boosting the operating capabilities of recycling operations. It symbolizes our dedication to providing industry-leading, innovative, and durable machinery.

our ifat fair and canton fair

2 times offline exhibitions IFAT fair and 2 times offline exhibitions Canton fair

get Beat price today.

Get an outstanding deal on our copper chopper machine currently! Take advantage of low rates and improve your recycling operations. Our machine is constructed for efficiency and durability, and it provides a low-cost alternative for processing copper wires and cables. It’s a good investment because of its superior technology and dependable performance. Don’t pass up this chance to enhance your recycling process while also saving money. Contact us right now to receive the best price and improve your recycling capacity.

the advantages

Few Points for copper chopper machine

The copper chopper machine is an important component in the recycling industry, designed to process and transform unwanted copper wires into recyclable granules. It has an advanced mechanism that assures full separation and extraction, resulting in high-quality output. Its design prioritizes lifespan and dependability in continuous operation, with an emphasis on minimizing operational disturbances and maintenance. The machine’s design incorporates user accessibility and safety, giving operators with a smooth experience.

Precision Separation

The copper chopper machine excels at meticulously separating copper from its insulation, ensuring high purity and great yield of copper granules suitable for cable recycling business.

Engineered for Longevity

Constructed with a focus on enduring the rigors of continuous use, the machine's design emphasizes reliability and a reduced need for frequent maintenance, ensuring ongoing operational efficiency.

Maintenance and Support

Designed for ease of use, the machine features intuitive controls and mechanisms, allowing for a straightforward operation that accommodates operators with varying levels of experience.

What We Do

Customized Design

We assess individual client requirements to develop copper chopper machines that align with their specific processing needs, optimizing their operational workflow and output efficiency. If the machines on the website still don't meet your needs, you can contact us for customized services.

Our approach involves stringent quality oversight throughout the manufacturing process. Each machine undergoes comprehensive testing to ensure it meets established standards of performance and longevity.

We provide extending assistance, facilitate installation, provide operating training, and ensure dependable maintenance services. Our client support aims to provide ongoing, efficient functioning, with a focus on rapid and effective service.

Why Choose Us?

Select us for our deep industry knowledge, high-quality machines, attentive customer support, great focus on technological advancements, and dependable maintenance method. We deserve your trust!

Effective Team Work

Our strong team integrates specialist skills to create and manage high-performance copper chopper machines, providing increased productivity and dependability.

25+ Years Experience

We provide precisely made copper chopper machines with over 25 years of expertise, promising reliability and effectiveness in recycling. Our customers leave good feedback for us voluntarily。

High Technology Factory

Find out an innovative production plant specializing in exquisite and efficient copper chopper machines with improved design for excellent performance and long-term dependability.

Flexible Payment Plan

Think about customizable methods of payment for the copper chopper machine, enabling a variety of financial situations and investment strategies.

How to Get copper chopper machine from us

Contact us to discuss your requirements, receive a full price, and begin the simple process of purchasing your copper chopper machine.

01.

Inquiry and Consultation

Contact our copper chopper machine experts today for guidance and customized solutions.

02.

Customization and Quotation

Request a copper chopper machine quotation specific to your operational and financial needs.

03.

Order Confirmation and Manufacturing

We carefully design your copper chopper machine after receiving your order to ensure the best performance and reliability.

04.

Delivery and After-Sales Support

Fast delivery, installation, training, maintenance, and 24/7 copper chopper machine support.

Lets Tell Us About Your granulator machine Needs

Let us know your requirements for a wire granulator machine, we will create personalized processing strategies to enhance your recycling operations and overall performance.

- Whatsapp/Viber: 008613772508206

- Email: coppergranulator@bsghrecycling.com

- Website: https://bsghgranulator.com/