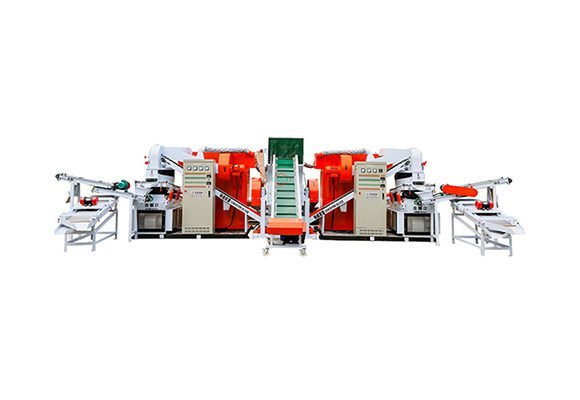

4 Sets Of BS-1200P Radiator Stripper Recycling Machines Delivered To Romania

At 11 a.m. on July 15, 2024, Beijing time, we sent four sets of BS-1200P radiator recycling machines to a Romanian customer who purchased his

BSGH Granulator allows you to customize your copper recycling equipment to your exact needs. We recognize the distinct requirements of each operation, which is why we provide extensive customization possibilities. Our skilled staff works together with you to create a machine that maximizes efficiency and productivity while fulfilling your individual needs. We value craftsmanship and quality at BSGH Granulator, ensuring that your customized machine performs flawlessly. Contact us immediately to discuss your customisation requirements and begin the process of moving toward a more efficient and effective copper recycling solution.

Explore our economical copper recycling machine, a solution that seamlessly integrates cost-effectiveness with exceptional performance. We understand the significance of cost-effectiveness in your copper recycling endeavors at BSGH Granulator.

Our copper recycling machine has been specifically designed to efficiently handle a wide range of cable diameters and types while ensuring minimal operational expenses. It has a straightforward interface and minimal maintenance needs, which decreases outage and costs.

Our design ethos is predicated on the necessity for longevity. We assure machines that can endure daily use by employing high-quality materials and precise engineering, thereby reducing the frequency of replacements and expensive repairs.

Moreover, we provide customization alternatives to accommodate the machine’s unique requirements, irrespective of the scope of your enterprise (industrial or small-scale).

By selecting BSGH Granulator, you are allocating your financial resources towards an economical copper recycling solution that effectively achieves desired outcomes. Become one of the contented clientele who have benefited from our unwavering dedication to excellence in pricing, quality, and customer service. Contact us immediately to discuss your copper recycling requirements and assist us in locating the most economical solution for your company.

BSGH Granulator targets quality in the production of your copper recycling machine. To ensure your complete satisfaction, we prioritize quality in all aspects of our machines. Strict quality control techniques ensure longevity and dependability. With our machines, you are able to concentrate on effective copper recycling rather than on frequent maintenance or replacement. BSGH Granulator provides exceptional quality for all of your recycling needs.

Regarding the raw material: the process involves cutting and drilling.

Following the initial processing of the raw materials, the subsequent stage involves subjecting them to a heat treatment process.

This stage primarily involves welding spare parts.

This phase focuses on treating essential machine components such the main shaft, air separator system shaft, rollers, eccentric shaft, and more. For optimal machine performance, this step must be precise.

This stage primarily involves welding the processed components together to create semi-finished equipment comprising the main crusher, air separator, and dust removal device.

Welding all finished spare parts into semi-finished products.

With semi-finished products, we conduct thorough debugging and operational testing, fine-tuning the machine for optimal performance after disassembly.

Following disassembly, we conducted meticulous polishing and painting. We then proceeded with reassembly and thorough debugging, giving rise to a brand-new copper granulator machine.

Leading China Wire Granulators

Can Compete with Euro Granulators

BSGH Granulator is a well-known manufacturer of copper recycling machinery in China. We are proud of our significant knowledge, ingenuity, and persistent commitment to supplying top-tier copper recycling equipment.

Our journey as a manufacturer began with a simple vision: to deliver cost-effective and efficient solutions for copper cable recycling enterprises. We have consistently pursued quality in both our products and services over time, earning the trust of numerous clients worldwide.

Quality and durability are important to us at BSGH Granulator. We develop and build our machines with cutting-edge technology and premium materials to ensure a long lifespan and peak performance. Our devoted team of engineers and technicians works tirelessly to develop equipment that meet the specific needs of each customer.

What distinguishes us is our unwavering dedication to customer satisfaction. We work closely with our clients to provide tailored solutions that meet their individual requirements. Our commitment goes beyond the first purchase; we offer extensive support and maintenance services to ensure that your copper recycling machine runs at peak efficiency.

Choose BSGH Granulator as your reliable copper recycling partner. Experience the distinction in quality, efficiency, and dependability that distinguishes us in the industry. Join our ever-growing list of delighted customers and let us assist you in meeting your recycling objectives.

As a manufacturer specializing in copper recycling machines, our profound technical expertise guarantees that each machine is meticulously crafted for efficiency and long-term durability.

We stick to the highest quality requirements in the manufacture of our copper recycling equipment. Each equipment is thoroughly tested in accordance with industry standards to ensure its dependability and longevity, especially when operating in adverse situations.

Our commitment to innovation allows us to constantly improve our copper recycling devices. We retain our dedication to pioneering solutions by assuring the efficiency and usability of our revolutionary copper recycling devices.

Our commitment to clients extends beyond copper recycling machine purchases. We offer ongoing technical support, maintenance services, and readily available critical components to ensure our clients can maximize their copper recycling machine's performance.

It is simple to acquire a copper recycling machine from us. Simply communicate your needs and concerns to our team, and we will assist you throughout the acquisition procedure in a seamless fashion.

Start the process by informing us of your exact requirements. Our team of professionals will carefully examine your specific needs and make recommendations for the best copper recycling machine to meet your goals.

We can customize the copper recycling machine to match your specific requirements. Once we have all the necessary data and criteria finalized, we'll provide you with a detailed price quote.

Once your order is confirmed and the payment formalities are finished, your copper recycling machine will be produced. Each machine is painstakingly manufactured to satisfy our exacting quality and performance criteria.

Your copper machinery for recycling will be delivered safely after production. We provide installation, operational training, and maintenance help to ensure its continuing functionality after purchase.

Specify your wire granulator machine needs. We styling solutions to your processing needs to maximize recycling performance and efficiency.

At 11 a.m. on July 15, 2024, Beijing time, we sent four sets of BS-1200P radiator recycling machines to a Romanian customer who purchased his

News Contact Us Email: coppergranulator@bsghrecycling.com WeChat/Whatsapp/Viber: +86 13772508206 Website: www.bsghgranulator.com Cooperate With BSGH Granulator, A Win-win Decision Good news! On June 28, 2024, BSGH Granulator

In early March, an Iraq customer visited our One-Stop Recycling Solution website. He discovered that our company offers a comprehensive range of metal recycling machines,

Tks for your interesting for our machine, can you tell me more about your requests so i can recommend you the proper machine?

Online | Privacy policy

WhatsApp us

Please fill in the following form(tell us your requests or you can choose from):

| D Series Different Capacity |

| 50KG/H, 70KG/H, 100KG/H, 200KG/H, 300KG/H |

| N Series Different Capacity |

| 300~500KG/H, 400~600KG/H, 1T/H, 1200~1500KG/H |

According above different capacities, tell us your requests, once we get your detailed information for your requests, we will contact you at the first time with professional solutions and support from buying to using.

Maximize your recycling efficiency with our compact and powerful metal chip briquetting machines. Whether you’re dealing with small batches or large volumes of metal scrap, we have the perfect solution to fit your space and production needs.

Contact us today for a free, customized quote and discover how our briquette press can help you boost productivity and profits.

Ready to Turn End-of-Life Solar Panels into High-Value Treasure?

Whether you need a standalone Frame Dismantling Machine, a precision Glass Removal Machine, or a complete Solar Panel Recycling System—we have the right solution for your business.

Contact Us Today & Get a Free Quote tailored to your PV panels!

Which kinds of material you want to process?

Please fill in the following form(give us your specific requests, the detailed the better, so we can give you an optimal solution at the earliest time):

From robust tools to advanced recycling machinery, we provide a comprehensive selection: cutting, moving, shearing, grap, baler, separation, a series of heavy-duty equipment engineered to meet the demands of diverse industrial operations and material types. Which kinds of function do you need? Send us your requests now to let our machine help you to get more profits.

Please fill in the following form(tell us your requests or you can choose from):

| Home use wire stripper machine |

| 1.5MM-38MM; 2-45MM; 2-76MM; 2-60MM; |

| Industrial cable stripping machine |

| 10-120MM; 10-160MM; 60-200MM |

According to your requests, I’ll recommend the suitable machine.

We have all kinds of radiator recycling machines, besides single radiator stripper machines and radiator recycling lines, radiator cutting machines.

Our machines are capable of processing all kinds of scrap radiators, including car radiators, water tank radiators and AC radiators, aluminum-clad radiators etc.

Our metal baler can processing all types of scrap metals, besides light metal and heavy metals; ferrous metal and non-ferrous metals;

our machine have from small pressure to big pressure 80T, 125T, 135T, 160T, 200T, 250T,315T and 400T, if you not know which pressure should you choose, so please send us your material picture below and ask for a free quote now!

We have:

Can you tell me which kinds of material you want to process? click below and send material picture.

Process Motor Shell | Motor Stator | Motor Shaft

Motor Shell Cutting | Motor Stator Recycling

Auto Starter Cutting | Auto Starter Pressing | Car Starter Heating | Car Starter Pulling Machine

Car Alternator Cutting Machine | Car Alternator Pulling Machine

Motor Stator Recycling Line | Motor Rotor Recycling Line | Whole Motor Recycling Plant

For Small Transformer Recycling

Compressor Shell Cutting Machine | Compressor Stator Recycling

Mainly for Recycling Ceiling Fan Motors

For All Kinds of Car Magnetic Switch

For All Kinds of Electric Bike Hub Motors

Mainly for Press All Kinds of Motor Parts | Support Customized

1: Get copper price today FREELY!

2: Enter into scrap metal group FREELY!

3: Leave your information, get a cable cutter for FREE!

4: ROI Analysis for FREE!

5: Get extra one year warranty for FREE!

6: Get usd100 coupon for FREE!

7: Get spare parts for FREE!

8: Best seller of the month FREELY!

Note: Your email information will be kept strictly confidential.

Note: Your email information will be kept strictly confidential.