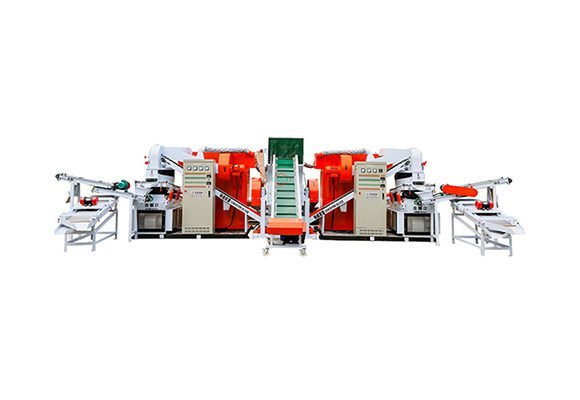

2 BS-D30 Copper Wire Granulators and 1 BS-D65 Copper Wire Granulators Were Deliverd To Argentina

We Have A Promotion China Double 11 Shopping Festival is coming, this is the only promotion of the year. In order to thank customers for their

BSGH Granulator allows you to modify your copper separating machine. Get a customized solution that fits your specific processing requirements. Because of our commitment to flexibility, you can choose configurations and settings that closely match your operational requirements. Experience increased recycling rate and efficiency with a copper separator machine tailored to your individual production needs. Choose BSGH Granulator for a customized solution that integrates seamlessly into your business processes.

Explore the unprecedented cost-effectiveness of BSGH Granulator’s copper separator machine, a one-of-a-kind solution designed to maximize your resource recovery process.

This equipment, built using efficiency in consideration, provides perfect separation of copper and other minerals while reducing running expenses to a minimum. Our commitment to price is matched by our unwavering commitment to quality, delivering a dependable, long-term solution for your recycling needs.

The BSGH copper separator machine not only reduces initial expenditure but also saves money over time due to its energy-efficient design. Reduced operational costs without damaging the high standards of material purity you require.

The simple controls simplify operation, reducing downtime and increasing productivity, making it an excellent choice for companies looking for a cost-effective yet powerful copper separation solution.

BSGH Granulator’s expertise can help you improve your recycling capacities by providing a cost-effective and efficient copper separator machine that is unique in the industry.

Experience the perfect blend of price and performance with a solution intended to fit your budget without sacrificing quality. Choose BSGH Granulator for an investment that will return dividends in both immediate and long-term operating efficiency.

We prioritize the quality of your copper separator machine at BSGH Granulator. Our constant dedication to excellence guarantees that each machine is meticulously crafted, ensuring longevity and dependability. Improve your recycling processes with a quality-focused approach that results in long-term performance and consistent outcomes. Experience exceptional quality in all aspects of our copper separator machines.

Processing raw materials involves both cutting and drilling procedures.

Following the initial processing of raw materials, the subsequent stage involves subjecting them to heat treatment.

This stage primarily involves welding spare parts.

This section processes important machine components such as the main shaft, air separator system shaft, rollers, eccentric shaft, and others. Precision in this phase is crucial to machine performance.

The welding of previously processed components into semi-finished equipment, including the main crusher, air separator, and dust removal device, is the primary focus of this step.

Assembling all completed components through welding to create semi-finished products.

After disassembly, we debug and test semi-finished goods. We modify the machine’s performance to ensure it works well before final assembly.

Once dismantling, we polished and painted carefully. After precisely reassembling and debugging, a new copper granulator machine was ready for use.

Leading China Wire Granulators

Can Compete with Euro Granulators

BSGH Granulator takes pride in our devotion to cutting-edge technology and exceptional craftsmanship in the creation of copper separator machines as a premier manufacturer.

We prioritize innovation and strive to be the market leader in high-performance material separation systems. Our cutting-edge manufacturing facilities and trained team ensure that each copper separator machine is of the highest quality and durability.

We understand our customers’ individual needs and offer a variety of adjustable features to personalize our separators to their requirements. Our commitment to quality extends beyond product creation to comprehensive support, including installation services, operating training, and continuing maintenance help.

Trust us to be your dependable partner, producing top-tier copper separator machines that revolutionize efficiency and dependability in the recycling business. BSGH Granulator provides quality and competence in all aspects of copper separation technology.

We have large technological competence as a producer of copper separator machines, ensuring that each machine is painstakingly constructed for efficiency and longevity.

We ensure high quality requirements during copper separator machine production. Each machine is tested against industry standards to ensure dependability and endurance, even in harsh conditions of operation. We guarantee the highest quality of every copper separator machine we supply, giving customers a reliable and long-lasting solution for efficient material separation in recycling processes.

Our products are constantly updated with new technology, showcasing our dedication to cutting-edge solutions. We make our copper separator machines the most innovative by stressing efficiency and usability. Staying ahead of technology ensures that our copper separation solutions meet or exceed industry standards and are easy to use. We deliver cutting-edge copper separator machines that combine innovation and practicality to boost recycling.

Our commitment to clients extends beyond the purchase of copper separator machines. We provide full technical support, maintenance services, and access to crucial components to ensure that our customers get the most out of their copper separator machines.

To purchase a copper separator machine from us, please contact our sales staff via our website or by phone. We’re eager to help you with your purchase.

Start by sharing your specifications with us. Our experts will assess your individual requirements and advise you on the best copper separator machine to meet your goals.

We can customize the copper separator machine to suit your specific requirements. Once we have finalized the data and criteria, we will provide you with a detailed price quote.

Your copper separator machine is produced after order confirmation and payment. Each machine is handcrafted to satisfy our high quality and performance standards. Our dedication to quality in every step of construction will ensure that your copper separator machine is efficient.

After production, your copper separator machine will be shipped safely. We provide installation, operational training, and continuous maintenance to ensure functionality after purchase. Trust us to produce a high-quality copper separator machine and provide the skills you need for smooth operation and maintenance.

Specify your wire granulator machine needs. We styling solutions to your processing needs to maximize recycling performance and efficiency.

We Have A Promotion China Double 11 Shopping Festival is coming, this is the only promotion of the year. In order to thank customers for their

News Contact us Email:coppergranulator@bsghrecycling.com Contact Ms.Wang TEL: +086 13772508206 Website: www.bsghgranulator.com Copper Cable Granulator Story On the first day of July, BSGH Granulator successfully shipped

Good news! BSGH Granulator delivered a heavy-duty wire stripping machine BS-AN125 to a UK customer successfully today. Case Detail On September 14, our UK customer

Tks for your interesting for our machine, can you tell me more about your requests so i can recommend you the proper machine?

Online | Privacy policy

WhatsApp us

Please fill in the following form(tell us your requests or you can choose from):

| D Series Different Capacity |

| 50KG/H, 70KG/H, 100KG/H, 200KG/H, 300KG/H |

| N Series Different Capacity |

| 300~500KG/H, 400~600KG/H, 1T/H, 1200~1500KG/H |

According above different capacities, tell us your requests, once we get your detailed information for your requests, we will contact you at the first time with professional solutions and support from buying to using.

Maximize your recycling efficiency with our compact and powerful metal chip briquetting machines. Whether you’re dealing with small batches or large volumes of metal scrap, we have the perfect solution to fit your space and production needs.

Contact us today for a free, customized quote and discover how our briquette press can help you boost productivity and profits.

Ready to Turn End-of-Life Solar Panels into High-Value Treasure?

Whether you need a standalone Frame Dismantling Machine, a precision Glass Removal Machine, or a complete Solar Panel Recycling System—we have the right solution for your business.

Contact Us Today & Get a Free Quote tailored to your PV panels!

Which kinds of material you want to process?

Please fill in the following form(give us your specific requests, the detailed the better, so we can give you an optimal solution at the earliest time):

From robust tools to advanced recycling machinery, we provide a comprehensive selection: cutting, moving, shearing, grap, baler, separation, a series of heavy-duty equipment engineered to meet the demands of diverse industrial operations and material types. Which kinds of function do you need? Send us your requests now to let our machine help you to get more profits.

Please fill in the following form(tell us your requests or you can choose from):

| Home use wire stripper machine |

| 1.5MM-38MM; 2-45MM; 2-76MM; 2-60MM; |

| Industrial cable stripping machine |

| 10-120MM; 10-160MM; 60-200MM |

According to your requests, I’ll recommend the suitable machine.

We have all kinds of radiator recycling machines, besides single radiator stripper machines and radiator recycling lines, radiator cutting machines.

Our machines are capable of processing all kinds of scrap radiators, including car radiators, water tank radiators and AC radiators, aluminum-clad radiators etc.

Our metal baler can processing all types of scrap metals, besides light metal and heavy metals; ferrous metal and non-ferrous metals;

our machine have from small pressure to big pressure 80T, 125T, 135T, 160T, 200T, 250T,315T and 400T, if you not know which pressure should you choose, so please send us your material picture below and ask for a free quote now!

We have:

Can you tell me which kinds of material you want to process? click below and send material picture.

Process Motor Shell | Motor Stator | Motor Shaft

Motor Shell Cutting | Motor Stator Recycling

Auto Starter Cutting | Auto Starter Pressing | Car Starter Heating | Car Starter Pulling Machine

Car Alternator Cutting Machine | Car Alternator Pulling Machine

Motor Stator Recycling Line | Motor Rotor Recycling Line | Whole Motor Recycling Plant

For Small Transformer Recycling

Compressor Shell Cutting Machine | Compressor Stator Recycling

Mainly for Recycling Ceiling Fan Motors

For All Kinds of Car Magnetic Switch

For All Kinds of Electric Bike Hub Motors

Mainly for Press All Kinds of Motor Parts | Support Customized

1: Get copper price today FREELY!

2: Enter into scrap metal group FREELY!

3: Leave your information, get a cable cutter for FREE!

4: ROI Analysis for FREE!

5: Get extra one year warranty for FREE!

6: Get usd100 coupon for FREE!

7: Get spare parts for FREE!

8: Best seller of the month FREELY!

Note: Your email information will be kept strictly confidential.

Note: Your email information will be kept strictly confidential.