copper wire granulator price

The price of a copper wire granulator is determined by various criteria, including its size, capacity, specialized features, and manufacturing quality. Due to their greater capabilities in processing bigger batches of copper wire more efficiently, larger machines with higher capacities and innovative features often attract a higher price. Furthermore, the production quality is an important factor in deciding the pricing. High-quality materials and construction not only ensure durability and lifespan, but also improve performance and require less maintenance, which can justify a larger initial expenditure. It is recommended to contact us directly for the most up-to-date price information. We can provide detailed prices and help you choose the correct granulator to fit your unique needs, taking into account aspects such as the volume of wire to be processed, the desired purity of the recovered copper, and any special features you might need for your recycling operations. Our team is eager to assist you in determining the best cost-effective and efficient option for your copper wire recycling requirements.

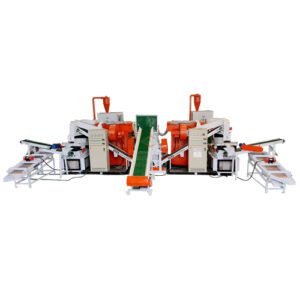

Our copper wire granulator Machines

We Ensure high quality copper wire granulator

We take great satisfaction in the superior quality of our copper wire granulators at our company. Our dedication to quality means that each machine is made to last, with unrivaled durability that can resist the rigors of rigorous operation. We recognize the importance of efficiency in recycling operations, which is why our granulators are designed to treat copper wire at maximum productivity while minimizing waste. Our equipment’ exceptional performance demonstrates our commitment to upgrading recycling technology. Our granulators are more than simply tools; they are partners in your recycling journey, assisting you in achieving successful solutions with every use. By selecting our copper wire granulators, you are investing in more than simply a machine; you are investing in a promise of quality, efficiency, and environmental stewardship. We ensure that each granulator meets the highest requirements, allowing you to concentrate on what is most important: efficient and effective recycling solutions.

-

Durable BS-D80 Scrap Copper Rice Machine for Sale

Read more -

Best Performance BS-N135 Cable Wire Recycling Machine For Sale

Read more -

99.99% Recycling Rate BS-N140 Wire Granulators From BSGHGranulator

Read more -

BS-N125 Copper Recycling Machine with Electrostatic Separator for Scrap Cables

Read more -

BS-N125 Copper Wire Recycling Machine for Scrap Cables

Read more -

400~700KG/H Hot Selling BS-N130 Cable Shredder Machine for Sale

Read more -

BS-F1000 Copper Wire Granulator with 1T/H Capacity from China

Read more -

Large Capacity Industrial Copper Cable Granulators for Sale BS-F3000

Read more

Various Models of Copper Wire Granulator Price

-

BS-D80 Copper Wire Granulator Price $30000+

D series dual shaft shredder + BS-D60 + Conveyor Belt

-

BS-N135 Copper Wire Granulator Price $50000+

BS-N125 + Dual Shaft Shredder + Electrostatic Separator

-

BS-N140 Copper Wire Granulator Price $60000+

ECO1000 + 2Sets Small Electrostatic Separator

-

BS-N125 Copper Wire Granulator with Electrostatic Separator Price $40000+

BS-N125 + Small Electrostatic Separator

-

BS-N125 Copper Wire Granulator Price $20000+

Single copper wire granulator BS-N125

-

BS-N130 Copper Wire Granulator Price $40000+

BS-N125 + N series Dual shaft shredder

-

BS-F1000 Copper Wire Granulator Price $50000+

ECO1000 + N series Dual shaft shredder + Conveyor Belt

-

BS-F3000 Copper Wire Granulator Price $90000+

ECO1000 + N series Dual shaft shredder + Conveyor Belt + 2sets Electrostatic Separator

Note: The above price will be changed according to different configurations.

CE Certificate for our Priced copper wire granulator

get Beat price today.

The BSGH Granulator offers various copper wire granulator models with different capacities and features. For current pricing and details, please contact us directly.

the advantages

Few reasons for copper wire granulator price

We consider the copper wire granulator’s size, power, processing capacity, and integrated features for determining our copper wire granulator’s price.

Crusher Size

The size of the crusher impacts the processing capacity of the whole granulator.

Power Requirements

Different models require varying levels of power for operation.

Processing Capacity

The capacity of the machine to process copper wire affects its price.

What We Do

The goal is to utilize our expertise and strive for excellence in our products, ensuring that customers receive the best value for their money and the highest quality products. We aim to have every customer leave satisfied, having received a product that exceeds their expectations.

Diverse Product Range

We provide an extensive range of copper wire recycling equipment, including various granulator machines and shredders that are suited to specific customer needs.

We prioritize our manufacturing of high-quality, efficient, and sustainable copper recycling goods, and we are committed to improving worldwide recycling techniques and machine performance.

We provide comprehensive client support, backed up by a competent technical team, assuring speedy and dependable help from installation to after-sales servicing.

Why Choose Us?

Choose us for we strive to provide high-quality, efficient, and environmentally friendly copper recycling products, supported by great customer service and technical experience.

Effective Team Work

Effective teamwork uses varied abilities, seamless communication, and a shared goal to create amazing results effectively and creatively.

20 Years Experience

With more than 25+ years of experience, we have deep comprehension, developed skills, and a track record of high-quality solutions and services.

High Technology Factory

Our high-tech manufacturing integrates cutting-edge machinery, procedures, and methods to produce high-quality products and services.

Flexible Payment Plan

Our customizable payment plans suitable customer financial needs and budgets, making them easy and convenient.

How to Get Wire Granulator from us

Contact us with your wire granulator needs. We’ll help you choose, customize, and acquire the right machine, making it effortless from inquiry to delivery.

01.

Inquiry and Consultation

Share your needs with us. Our experts will assess your needs and recommend the best wire granulator machine to meet your goals.

02.

Customization and Quotation

We'll customize the wire granulator to your needs. After determining your specifics, we'll send a detailed price to meet your demands.

03.

Order Confirmation and Manufacturing

After payment and order confirmation, we will manufacture your wire granulator. Our high quality and performance criteria are met in every unit.

04.

Delivery and After-Sales Support

The wire granulator machine will be sent securely after completion. To ensure optimal functionality, we provide installation help, operational training, and maintenance assistance after delivery.

Lets Tell Us About Your granulator machine Needs

Specify your wire granulator machine needs. We styling solutions to your processing needs to maximize recycling performance and efficiency.

- Whatsapp/Viber: 008613772508206

- Email: coppergranulator@bsghrecycling.com

- Website: https://bsghgranulator.com/