copper wire granulators

- Rivals the quality of top European brands, boosting a service life of over ten years under normal use.

- Integrates multiple advanced separation technologies, we maximize the copper recovery of 99.9% from your scrap wires.

- Handles every type of scrap wire including copper and aluminum wires, armored cables and ACSR cable no matter size, thickness, or hardness.

- With over 30 years of experience, we offer one-stop service to help you resolve all your questions about the machine.

copper wire granulators for diverse Cables

Our scrap copper wire granulator is engineered to handle a wide range of material types with maximum recovery efficiency and operational reliability. We specialize in three core machines: D series copper granulator, N series wire granulating machine and ACSR copper wire granulator line. Each system combines advanced separation technology, robust construction, and energy-efficient operation to deliver pure copper outputs and maximize your ROI.

D series copper granulator is designed for small to medium-scale recyclers and startups looking for an efficient entry-level solution.

- Ideal for processing various common copper wires

- Compact and takes up less space

- Competitive price with 99.9% separating rate makes it the most cost-effective

- Best cost performance

N Series Copper Granulator

Engineered for high-volume processing, N series copper granulator offers full-scale granulation and separation capabilities.

- Efficiently handling fine and miscellaneous wires

- Maximum processing capacity up to 3T/H

- 100% pure copper throughout comes from comprehensive configuration

- For demanding customers

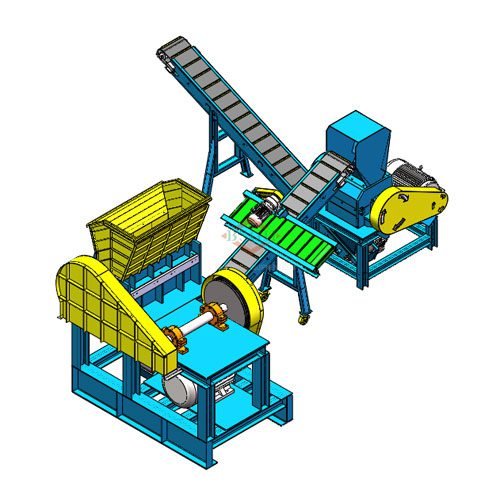

ACSR Copper Granulator

The ACSR cable granulator line is built for ACSR cables and big armoured cables, have strong power and good performance.

- It can separate aluminum, steel and iron from waste cables up to 100 mm in diameter.

- Strong shredding power + high output

- Replace different screens to control particle size

best copper wire granulators for sale

The biggest copper wire granulators manufacturer in China, BSGH Granulator, provides 100+ professional copper wire granulators. We offer both standard models and custom solutions, designed to handle almost every type of copper wires with 99.9% recycling rate — helping you maximize profits.

- Processing capacity: Standard models range from 40kg/h to 2000kg/h, with custom models reaching 3000kg/h.

- Wide applications: all scrap copper and aluminum wires from small to large diameter, including square wire, communication cable, household cable, soft rubber cable, automotive cable with tape, ultra-fine wire less than 1mm, and miscellaneous wire

- Excellent performance for both copper and aluminum wires.

- CE certified approval

- 12-month warranty

- Brand name: BSGH Granulator

BS-S10 single-phase Copper Wire Granulator

• Capacity: 40-60kg/h

• The most powerful single-phase copper granulator on the market

BS-S15 mini Copper Wire Granulator

• Capacity: 40-60kg/h

• Smallest granulator that can easily handle automotive wiring

BS-D75 Small Copper Wire Granulator

• Capacity: 70kg/h

• Smallest three-phase model, single-phase is also available.

BS-D10 home Copper Wire Granulator

• Capacity: 100kg/h

• Hottest selling for homeuse customers

BS-D30 Homeuse Copper Wire Granulator

• Capacity: 300kg/h

• Hot sale in USA and Europe

BS-D60 Scrap Copper Wire Granulator

• Capacity: 300-500kg/h

• Advanced and excellent

BS-N125 medium-sized Copper Wire Granulator

• Capacity: 300-500kg/h

• Durable and high-end

ECO1000 big Copper Wire Granulator

• Capacity: 1000kg/h

• The most cost-effective large model with two separation systems

BS-F1000 industrial copper wire granulator

• Capacity: 1000-1200kg/h

• ECO1000 cable granulator + double-shaft pre-shredder

BS-F3000 Heavy-duty Copper Wire Granulator

• Capacity: 1200-1500kg/h

• Largest standard model, high performance & durability

BS-A1300 Copper wire granulator

• Capacity: 2000-3000kg/h

• Specially customized model, supporting forklift feeding

Operating videos of copper wire granulators

Below are several videos of our copper wire granulator machines in action. You can see that each one is capable of thoroughly separating copper and plastic particles, resulting in clean, bright, 100% pure copper and plastic particles, both of which can be sold at a premium price.

Playlist

1:17

0:36

0:41

1:07

0:16

0:30

1:32

2:35

0:51

Optional systems for copper wire granulators

Maximize copper purity and recovery rates with our supporting equipments, designed for flexible and high-performance operation. BSGH copper granulator can be configured with two kinds advanced separation machines to match your specific material challenges and output targets.

Necessary equipment for ferrous cables - magnetic separator

Magnetic separators are essential equipment for copper wire granulators to processing iron-containing cables. They precisely separate various magnetic materials from the crushed mixed particles without affecting the final product, ensuring 100% purity and no residual impurities in the recovered copper.

- Separate iron from copper, providing you with dual economic benefits.

- We offer a variety of machine types, including belt magnetic separators, high-intensity magnetic separators, and self-unloading magnetic separators.

- They effectively protect downstream equipment from damage caused by hard iron.

The secret weapon to improve recovery rate - electrostatic separator

If you need to process large quantities of extremely fine wires less than 1mm, adding an electrostatic separator for your copper wire granulators is highly recommended by BSGH Granulator, divided into D series and N series.

Because the weight difference between copper and plastic among thin wires is small, air separators cannot accurately sort them all. Some copper granules may mix with the plastic particles, resulting in copper loss.

After discharging from the plastic outlet, the electrostatic separator further sorts the mixed granules again, reducing copper loss. This increases copper recovery rates and makes plastic purer and more profitable.

your best choice

Advantages of copper wire granulators

automatic design

With fully automatic design, only 1-2 operators can complete the entire cable recycling process, significantly reducing workforce costs.

precision-engineered

Each component is precision-engineered to fit perfectly, making installation and disassembly quick and convenient.

Dust-Free

Equipped with advanced pulse dust collection equipment, the recycling process will not generate dust or pollutants, meeting global environmental protection standards.

PLC system

The PLC system can help you monitor machine status in real time such as freely adjust wind speed, vibration frequency, etc.

easy to operate

Stable and excellent performance, able to maintain the best status during continuous and uninterrupted operation.

Low maintenance

Low maintenance frequency, the blade can be used multiple times after sharpening, with short downtime and low maintenance cost.

Leading copper wire granulators factory in China

With over 30 years of dedicated expertise, we are proud to be China’s earliest and most trusted manufacturer of copper wire granulators—leading the industry since 1995. Today, our high-quality copper granulators are trusted by more than 100,000 customers across 80+ countries and regions worldwide. We’ve built lasting relationships based on reliability, innovation, and mutual success. Whether you’re processing household cables or industrial wiring scrap, our machines deliver purity, performance, and profit—backed by three decades of engineering excellence.

Join global recyclers who choose experience and innovation. Let’s transform your recycling operation easier together.

CE certificate

All our copper wire granulators pass CE certificate, you can rest assured to export to Europe.

FAQ

I need to process both fine wire and a small amount of armored cable, and investing in an ACSR chopper isn't cost-effective. Is there a better machine for me?

Yes, we recommend purchasing an additional wire stripping machine. You can use the copper wire granulator for fine wire and the wire stripping machine for thicker wire and armored cable.

Can I choose the motor brand myself?

Yes, we support customized motor brand and power.

Can the copper wire granulators separate copper and aluminum?

No, please do not feed copper and aluminum wires together into the machine; you can process separatedly.

What should I do if the copper wire granulator machine breaks down?

Don't worry. Our copper wire granulators won't break down under normal use. Even if they do, we're online 24/7 to help you resolve the issue quickly.

How can I pay?

We accept T/T payment. You pay 30% of the machine price, and we'll arrange production. After the production is completed, we will send you a testing video, and you will pay the remaining 70%. We'll arrange shipment immediately after receiving the final payment.

copper wire granulators customer project

Our copper wire granulators customers are spread all over the world: USA, JAPAN, Saudi Arabia, Thailand, UAE, Europe etc., This is just a very little customer case. If you want to know more, pls contact our sales staff to get more details.