Your Reliable Partner In China

leading copper wire Grinder machine factory

A copper wire grinder machine, also known as a copper wire granulator, is designed to process various types of copper wires by separating the copper from the insulation. These environmentally friendly machines crush cables into pure copper and pure plastic through processes such as crushing, air separation, and vibrating screen separation. This not only prevents the waste of metal resources but also allows you to generate significant profits.The BSGH copper wire grinder machine uses the highest quality materials and the most advanced technology, ensuring a superior user experience. By investing in this machine, you can efficiently recycle copper wires while maximizing your returns.

──────── Product Selection ────────

Which kinds of copper wire grinder can you choose at BSGH company?

- We have more than 60 types of copper wire machines for you to choose from.

- Capacity from 50~2000KG/h, you can choose it according to your needs.

- The copper wire grinder machine price range is USD4900~USD158000+.

- We can provide you with customized services based on your requirements.

Model | Capacity(kg/h) | Weight(KG) | Power(KW) | Dimension(MM) |

1200~1500 | 18000 | 120 | L15500*W9500*H2500 | |

1000~1200 | 8700 | 98 | L10000*W9500*H2200 | |

800~1000 | 5800 | 76 | 7200*7500*2200 | |

400~700 | 5000 | 67 | 12000*3500*2250 | |

300~500 | 3200 | 40.5 | 3900*2000*2250 |

copper wire grinder machine supplier

Copper wire grinding is a critical process in many industries, from electronics manufacturing to scrapyard recycling; from personal to industrial use plant. Ensuring the efficient and precise grinding of copper wires can significantly enhance productivity and product quality, this is very important for us, so finding a reliable and experienced copper wire grinder machine supplier becomes essential. We BSGH Granulator, as the supplier stands out in the market, offering top-of-the-line machines that meet the highest industry standards.

to use our machine what you can get?

For every customer, they know what they want to get! Choosing our company as your supplier for copper wire grinder machines offers a multitude of benefits that are designed to enhance your operations and ensure you get the most out of your investment:

Durable and quality

Our machines are built to the highest standards, using good materials and advanced manufacturing techniques. This ensures that our grinders are not only durable but also capable of delivering consistent, high-quality performance over extended periods of operation.

pure copper

advanced technology

We integrate the latest technological advancements into our machines, such as automated control systems, precise grinding mechanisms, and best frequency inverter. These innovations enhance the efficiency, accuracy, and overall performance of our copper wire grinders, ensuring they meet the demanding needs of 99.9% recycling rate.

Comprehensive Support

Our commitment to customer satisfaction extends beyond the sale of our machines. We offer extensive after-sales support, including installation assistance, operator training, routine maintenance, and troubleshooting. Our dedicated support team is always available to ensure your machines operate smoothly and efficiently.

Proven Track Record

Our long-standing reputation in the industry is built on years of delivering reliable, high-performance machines. Numerous clients from various sectors have successfully implemented our grinders into their operations, contact us to get the comments now!

Main components

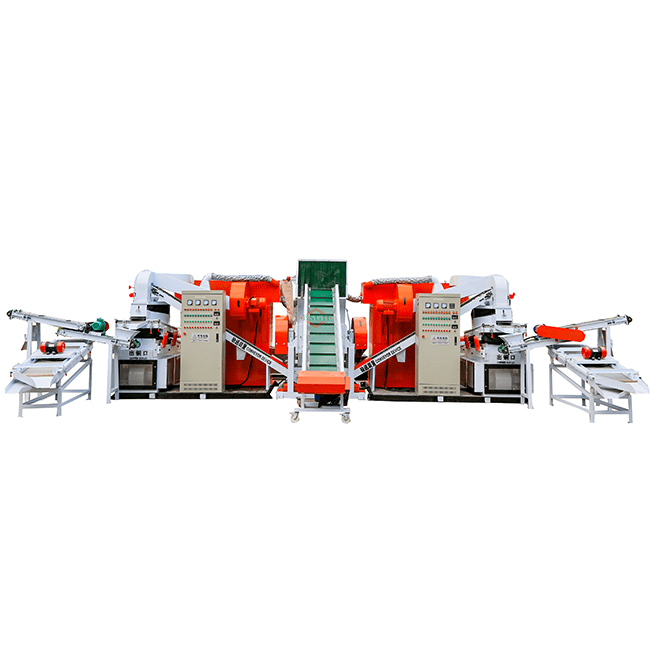

Our copper wire shredding machine consists of one main big crusher, 2 air separator systems with 4 small table vibrators.

Conveyor Belt

Conveyor belt will send your raw material into crusher, you only need to put scrap cables into conveyor belt.

Conveyor Belt

The main crusher is the most important part of the copper wire grinder machine operation process. It will crush the waste cables into mixed particles of metal and plastic for subsequent operation.

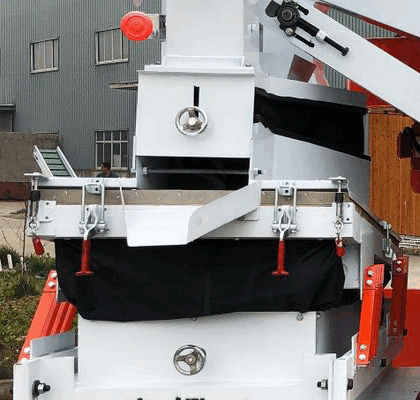

Air Separator

Separate the crushed raw material into pure copper granular and plastic granular. The principle of separation is that two different densities of materials in a certain angle, air blower, vibration of the process of deflection resulting in the separation of materials.

Small Table Vibrator

This machine is mainly plays the role of secondary separation, once the material is too complicated or complex, after this function, then you can get the pure copper and pure plastic.

About Us

Founded in 1995, our company has been a leading supplier of copper wire grinder machines for more than 25 years. Our mission is to provide cutting-edge solutions that help industries achieve their goals efficiently and sustainably. With a strong focus on innovation and customer satisfaction, we have built a good reputation in our customer group in the field.

1995

Establish in

100+

Workers

60000+

Factory Space

30+

CE and Certificate

Certificate

Our Ifat Fair And Canton Fair