Electric Motor Recycling Machine

BSGH Granulator’s scrap electric motor recycling machines represent the epitome of professionalism in the realm of waste motor recycling, our company machines are meticulously designed and manufactured to exceed expectations according to actual experience in this industry, from machine design to actual final products, every aspect and angle of our machines undergoes rigorous calculation, testing to ensure optimal performance and durability. What you see is the culmination of our relentless dedication to perfection, resulting in mature products that stand as a testament to our commitment to quality and innovation in motor recycling technology, showing mature products that stand as a testament to our commitment to quality and innovation in motor recycling technology.

BSGH Granulator

Best electric motor recycling machine in the world

The electric motor recycling machine in BSGH Granulator’s company has a good reputation in the recycling industry because of its high efficiency, good quality and durability. Our series of products is constantly being upgraded and modified, on the premise of basic functions ensuring, We also make some changes according to the needs encountered by machines in recycling practice, each machine is similar but unique. In this way, the electric motor recycling machine series can ensure the diversification and personalization and the needs of every customer can be well met. The advantage of our motor recycling machine is that it can cut the copper winding or stators smoothly and easily. During the pulling process, the copper winding can also be successfully taken out wholly and completely. The whole recycling process is automatic helping you save labor costs.

most popular electric motor recycling machine models technical datas

| Model | Power(KW) | Weight(KG) | Capacity(PCS/H) | Net Diamension(L*W*H, MM) |

|---|---|---|---|---|

| BSM-20 | 5.5 | 414 | 80~100 | 1220*940*920 |

| BSM-30 | 5.5KW | 395 | 60~80PCS/H | 2310*770*950 |

| BSM-40 | 7.5 | 670 | 0~120PCS/H | 1940*1430*1150 |

| BSM-50 | 7.5 | 650 | 40~60PCS/H | 2140*800*730/950*540*780 |

| BSM-60 | 4 | 508 | 80~120 | 1370*1040*1460 |

| BSM-70 | 3 | 430 | 200~300 | 1500*650*800 |

| ST-400 | 5.5 | 1100 | 8~30 | 1800*900*1950 |

Machine maintenance and precautions

- Check the electrical box of the machine regularly to avoid water or moisture.

- The power socket and sheath should be replaced if damaged.

- The running tracks on both sides of the cutting machine need to be oilevery day. It is best to add lubricant more than twice a day.

- The claws need to be lubricated with lubricating oil regularly. It is best to add lubricant more than twice a day.

- Do not pile up flammable objects around the machine to avoid dangerous accidents.

- Check the oil pipeline to prevent leaks.

structure of the scrap electric motor recycling machine

The structure of all our company’s motor recycling machines can be basicly divided into two parts depending on functions, they have similar function and similar structure, One is the cutting part and the other is the pulling part, just in order to realize the function maybe have different form of cutting or pulling.

Cutting part

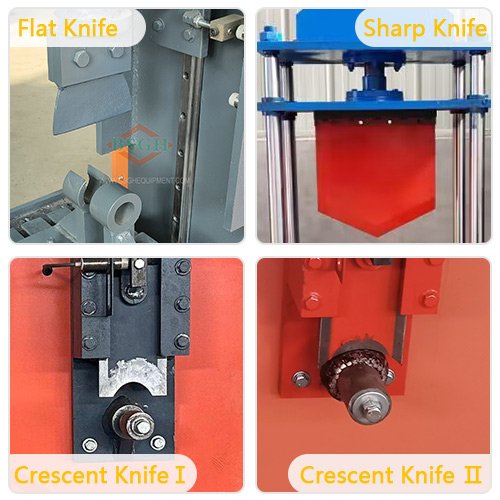

The blades is used to cut motor case or motor stator can be divided into three typs: Flat blade cutting, Sharp Blades Cutting and Semi-Rod Blades Cutting, each types of blades also have different shapes.

Flat blade cutting: This type blades is used to cutting the motor case. ST-400 and BSM-50 are equipped with it.

Sharp Blades Cutting: It is designed for halve the motor stator. Machines such as ST-400 and BSM-50 use this kind of blades too.

Semi-Rod Blades Cutting: It is used to cut the copper winding at one end of the stator leading the pulling process more easier. MR-W, BSM-10/20/40/60 and BSC ets, mainly rely on this type.

Different blades have different uses. They are all made of high hardness, good quality and wear-resistant materials.

pulling part

It mainly consists of claws of different sizes, some machines also add hydraulic clamps. They are used to handle stators of different diameters.

- 4-claw is mainly used in transfomer recycling machine.

- 6-claw is mainly in ST-400, processing diameter about 80~200mm.

- The 8-claw is mainly used to handle stators below 120mm.

- 12-claws mainly to process stator diameter 90~160mm, silicon steel thickness inner 120MM.

- The 16-claw aims to process stators 120~ 180mm, steel thickness under 160mm.

- The hydraulic pliers can deal with stators with larger diameters, for standard machine upto to 500MM.

Note: It is worth mentioning that some models machine cutting and pulling functions of motor recycling machine can be used at the same time, which can effectively improve the efficiency of the machine.

25+ experience in recycling fields

10+Years experience in motor recycling

With over a decade of experience in scrap motor recycling, BSGH Granulator has become a trusted leader in the industry. We have developed a diverse range of recycling machines designed to handle various scrap motor materials with precision and expertise. Each machine in our lineup is engineered to address the unique requirements of specific motor types, ensuring efficient and effective processing.

Leveraging our extensive experience and industry insights, we have created specialized solutions to tackle various challenges encountered in motor recycling. From small-scale to large-scale operations, our machines deliver exceptional performance and versatility, catering to the diverse needs of our clientele.

Moreover, our company’s commitment to quality is evident in the recognition we have received. Our products have obtained CE certification from the European Union, underscoring their compliance with rigorous safety and quality standards.

Manufacturing for last long: leading electric motor recycling machines

About electric motor recycling machine manufacturer

As the sole and leading professional scrap motor recycling machine factory in the world, BSGH Granulator’s company takes responsibility for leading the industry standards, we develop types of scrap motor recycling machines for different types of raw materials, more than 10 kinds; While many overseas markets lack professional solutions for various scrap motors, we at BSGH Granulator have risen to the challenge, offering specialized solutions for even the most unique and complex motor types, just like new energy motors to ceiling fan motors and car motors, our comprehensive range of machines is designed to meet the specific requirements of each motor category with precision and efficiency. BSGH consistently upholds a commitment to research and development, pushing the boundaries of motor processing capabilities across diverse sectors, our products are crafted to guarantee the utmost consumer satisfaction and keep our position as industry leader.

why us?

To cooperate with BSGH Granulator company, you can get the best cost-effective machines and the really good products, your machine and your money are all safe with us, you can rest assured and also can get 100% satisfaction.

Sole in the world

most complete

10+ years experience

60000+ square meters

10+ professional technician

Why do we need this machine?

Motors exist in all aspects of people’s production and life, they are involved in a wide range of business and scope which means there are a lot of scrap motors as well. How to explore the value of these scrap motors and make them benefit human life is particularly important. Therefore, the waste motor recycling machine was born, Its emergence allows a large number of waste motors to be recycled.

Waste motors are mainly found in household appliances and industrial equipment including washing machines, air conditioners, electric vehicles, fans, machine tools, exhaust fans, car engines, compressors, etc. According to the structure of motors, they are mainly divided into ordinary motors and special motors. So, we have different types of motor recycling machines to handle them.

What can we get after recycling through the motor recycling machine?

In the realm of recycling, scrap motors present a valuable opportunity for resource recovery. These motors are primarily comprised of silicon steel and copper windings. Our cutting-edge recycling machine specializes in efficiently extracting the copper metal from these windings without any loss. By utilizing our technology, the entire copper windings can be obtained, ensuring maximum yield and improve efficiency of the recycling process.

Let our machine simplify your scrap motor recycling process

Are you fed up with the complicated process of recycling scrap motors? Well, fret no more! Our company’s advanced machine is here to make your recycle easier. Scrap motor have too much types, send me your requests now and get the best and cheapest solutions for you.

FAQ

This is a good questions, it will according which kinds of motor you process, pls contact our professional sales manager and talk more.

We suggest the stator diameter up 15 cm to use small electric motor wrecker machine. For below 15cm diameter motor stators ,there have two solutions, it can improve effciency greatly:

1.)Use the motor stator breaking machine, first cut in small pieces,then feeding into the plant BSP-200.

2.)Or change the more bigger machine BSP-300, you can put whole motors into processing directly.

Sorry, my friends, because of scrap motor structure is complicated and varies types, so for each kinds of motors, there’s also have special ways to deal with.

Yes, sure, normally we recommend customer 85KW; but if you need smaller power, we have simple one can meet your demands, only 25KW, smaller and cheaper.

Leave your questions here to get what you care, send me NOW!