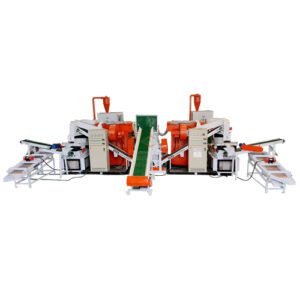

Best hydraulic shredder For Sale

Single-shaft shredder is also called hydraulic shredder, because it has a hydraulic system, our hydraulic system is pushiing scrap materials from up to down,more efficiently than traditional in the market. this machine is a professional equipment specially designed to pre-process various waste cables by BSGH Granulator. It is suitable as a pre-shredder and is always used together with a copper wire granulator. Our hydraulic shredder adopts an enlarged crushing chamber, which can shred waste cables more efficiently, with a processing capacity of 3~4T/H. In addition, our hydraulic shredder is also equipped with an upgraded hydraulic pushing system, which adopts a longitudinal pushing method from top to bottom, accurately solving the problem of empty push in ordinary pushers. It is your best choice to reduce the size of waste cables before using the copper wire granulator.

We ensure high-efficiency hydraulic shredder

you can trust our High-quality machines

Our latest hydraulic shredder adopts the enlarged shaft, specializd blades design for pre processing scrap cables or wires, which not only improves processing capacity to 3~4T/H but also supports forklift feeding, it greatly reduces the feeding time and improves the crushing efficiency of the machine. The single-axis design enables the hydraulic shredder to crush the waste cables into smaller 6~15cm long strips, convenient for storage and feeding to the copper wire granulator.

The hydraulic drive system allows the machine to achieve high-torque crushing and overload protection, ensuring the high efficiency, reliability, adaptability and safety of the hydraulic shredder. The pusher can be operated remotely, and the hydraulic rod has a fast pull-back speed, which effectively reduces the gap time. The entire process can be continuously loaded by a forklift, realizing the mechanized operation.

- Our methodlogy

Hydraulic shredder Process

The hydraulic shredder has a main axis with many blades installed on it. When the machine is running, the square knife hooks the material and the hydraulic auxiliary pushing system pushes the material from up to down, ensuring that the waste cables are efficiently shredded into 6~15cm long strips. Finally, the conveyor belt coveys the pre-processed waste cables to the storage transfer device or the main crusher.

Hydraulic Shredder Specification CE Certificated | |

Application Material | All Kinds Of Scrap Cable Wire |

Capacity | 3-4T/H |

Voltage | 380V 50Hz Or Customized |

Total Power | 113.7KW |

Main Machine Power | 110KW |

Hydraulic Station Power | 1.5KW |

Conveyor Belt Power | 2.2KW |

Feeding Hole Size | L≤1600mm, W≤1300mm, H≤1000mm |

Copper and Plastic Granlues Size | 6-10cm |

Optional parts you can choose

Conveyor Belt

Storage transfer device

hydrauic shredder

Contact us

Whether you have questions about the hydrualic shredder or want to be recommend a suitable hydraulic shredder model for you, you can contact us directly and we will provide you with a unique solution.

specially designed to solve your pain points

Newest hydraulic shredder

-

The hydraulic shredder can be fed directly by a forklift, which is more efficient and saves labor costs. Only one operator can run the machine.

-

Ordinary pre-shredder requires manual uniform feeding, which is time-consuming and labor-intensive, and has high labor costs.

-

Hydraulic shredder: Single-axis design, can crush waste cables into smaller sizes of 6~15cm. Use square knives to hook materials, the machine will not be stuck due to too many raw materials in the crushing chamber, and the knife edges can be used alternately.

-

Ordinary pre-shredder: Double-axis design, can only shred waste cables into 5~25cm. No overload protection, if there are too many raw materials in the shredding chamber, the machine gets stuck.

-

Hydraulic shredder adopts a hydraulic auxiliary pushing system. Its hydraulic push puller can accurately push the cable to the blades to avoid idling.

-

When processing scrap cables, ordinary single-shaft shredders are prone to not being able to hook the cables, causing the machine to run idle.

-

Hydraulic pusher: To avoid empty push, we upgraded the hydraulic shredder's pushing system. It uses the method of pushing materials from up to down, ensuring that the hydraulic push puller can push the cable every time it extends, thus improving the shredding efficiency of the machine.

-

Ordinary hydraulic push shredder: It uses the method of pushing materials horizontally. When the material load in the crushing chamber is insufficient or the material is misplaced, the push puller may extend but fail to contact the raw materials, resulting in an empty push.

Why do you need to add a pre-shredder to your copper wire granulator?

getting twice the result with half the effort

Pre-shredder plays a crucial role in copper granulator systems for higher recycling efficiency, longer service life, and lower risk of the machine getting stuck.

Reduce the size of waste cables

The pre-shredder shreds the waste cables into smaller sizes that are easier to process, preparing them for further processing in the copper wire granulator.

Extend the service life

Using a hydraulic shredder to pre-process the waste cables, it can effectively reduce the wear of the main crusher blades when crushing the cables and the impact of a large number of cables entering the machine, making the copper wire granulator more durable.

Improve production efficiency

The small size of waste cables can make the recycling process faster and smoother, thereby improving the production efficiency of the copper wire granulator.

Reduce the stuck risk

The hydraulic shredder controls that only materials of appropriate size enter the copper wire granulator, minimizing the risk of the main crusher getting stuck and ensuring that the copper wire granulator always maintains the perfect working condition during operation.

Why choose us

Your Professional High Quality hydraulic copper shreder machine supplier

BSGH Granulator is a Chinese company specializing in the research, design, manufacture and sale of various scrap copper recycling machines. We provide a variety of wonderful copper recycling solutions designed to help you maximize your profits and minimize your costs. Our machines are hot-selling in more than 80 countries and regions around the world, and have won unanimous praise from customers worldwide for their high-cost performance, high durability, and best working performance. You can feel confident in your decision to partner with us, and we will try our best to provide you with the best machines and services.

Rich experience

BSGH Granulator has been in the copper recycling industry for more than 25 years. Over the years, we have accumulated rich experience and sufficient industry expertise, cultivated a very professional team, and developed mature design and machine manufacturing technology. It can be said that choosing us is choosing the most reliable business partner.

Strict quality control

We regard quality as the most important factor in the copper recycling machine manufacturing process. We have formulated the highest quality standards and control plans, paying attention to every detail of the machine. We will conduct multiple comprehensive tests on the machine during the production process and send you a test video before shipment to ensure that the machine we send out is of the highest quality.

One-stop service

We provide comprehensive and thoughtful one-stop service. Before sales, we will give you the most professional machine selection suggestions and provide perfect customized solutions based on your needs. We also support circuit design, factory design, and machine placement design. During the sale, we will update you on the machine's production progress in time and continue to pay attention to the machine before you receive it safely. After-sales, we provide a one-year warranty service and a lifetime 24-hour online response service to help you solve all problems encountered during the use of the machine.

our ifat fair and canton fair

2 times offline exhibitions IFAT fair and 2 times offline exhibitions Canton fair

Lets Tell Us About Your shredder machine Needs

Specify your cable granulator needs. We styling solutions to your processing needs to maximize recycling performance and efficiency.

- Whatsapp/Viber: 008613772508206

- Email: coppergranulator@bsghrecycling.com

- Website: https://bsghgranulator.com/

hydraulic shredder videos

you can assemble to following machines

-

99.99% Recycling Rate BS-N140 Wire Granulators From BSGHGranulator

Read more -

BS-D30 Wire Grinding Machine with 300KG/H

Read more -

Best Price BS-D65 Electrostatic Separator Copper Wire Granulator for Sale

Read more -

Dry Copper Wire Granulating Machine BS-D600 for Sale | 400KG/H

Read more -

400~700KG/H Hot Selling BS-N130 Cable Shredder Machine for Sale

Read more -

Cheap Cable Granulators ECO1000 With Conveyor Belt and 4 Small Vibration Table

Read more -

BS-F1000 Copper Wire Granulator with 1T/H Capacity from China

Read more -

Large Capacity Industrial Copper Cable Granulators for Sale BS-F3000

Read more