Powerful processing capabilities help you quickly obtain benefits

Industrial Cable Shredder for Recycling Copper and Aluminum Cables

Introducing the forklift feeding BS-A1300 cable shredder for commercial use from BSGH Granulator – a heavy-duty machine engineered for efficient recycling of scrap wires and cables, provide you broken-free, built to last, reducing operation costs, the best equipment for various scrap yards, cable recycling factories, scrap metal recycling centers, etc.

BS-A1300 cable shredder machine manufacturer

BS-A1300 cable shredder is a patented product designed by BSGH Granulator, especially used for recycling large quantities of scrap copper and aluminum wires, better with a diameter below 30mm. The processing capacity can reach 2000-3000KG/H, efficiency is in a leading position in the world and it is a unique big machine.

This machine supports continuous forklift feeding, eliminating the need for uniform feeding while maintaining excellent recycling results, without the risk of getting stuck from excessive material. This enables automated, mechanized recycling of waste cables, significantly reducing the need for manual operation. With just 1-2 operators, the machine can run smoothly and efficiently.

Machine Gallery

If you want a machine with a smaller processing capacity, we strongly recommend you choose our BS-A1100 wire shredder machine.

Cost-effective BS-A1100 wire shredder machine

BS-A1100 is a also heavy-duty industrial wire shredder machine that can also be fed by a forklift, saving time and effort. Its processing capacity is about 1200-1500KG/H. Although smaller than BS-A1300, they both have the same sturdy structure and long service life. In addition to various waste cables, BS-A1100 wire shredder has strong power and can process waste motor copper windings. Due to its special design, it has become a favorite of many large recycling plants in Europe and South America.

Machine Gallery

Choose US your best choice

industrial Cable Shredder To Maximize Your Recycling Efficiency

High Resource Recovery Rate

Cable shredder can achieve high-precision copper-plastic separation while greatly improving production efficiency. Through at least two separation steps, 99.99% of copper resources in waste cables can be extracted from scrap cables. At the same time, we also have auxiliary equipment to help process special cables, ensuring that copper resources can be recovered to the maximum extent from almost all types of cables.

Remarkable Economic Results

Our industrial cable shredder machines process cables and wires into smooth, bright copper granules with no oxidation or impurities such as plastic particles, achieving 100% purity. Also with higher processing capacity, these ensures you can get higher economic returns for you.

Sturdy construction

Compared to common copper cable shredders, BS-A1300 and BS-A1100 feature a more robust structure and a thicker, sturdier body. Ordinary copper cable shredders may become jammed if they are fed too much material at once, whereas our heavy-duty models are designed with an exceptional load-bearing capacity. Not only do they support forklift feeding without the risk of jamming, but they are also more durable and resistant to damage, ensuring long-lasting performance.

Low maintenance requirements

When designing our machines, we prioritized the cost-effectiveness of recyclers, ensuring low operational and maintenance requirements. Our cable wire shredder consumes around 20% less energy than similarly-sized machines, minimizing power usage. Built with high-quality components, it is durable with minimal wear, reducing the need for frequent repairs and replacements, and minimizing downtime. In the long run, the savings in operating costs far exceed the initial price of the machine, making it a brilliant and cost-effective investment.

Environmental protection and zero pollution

Our machine is designed to promote the recovery and reuse of copper resources, reducing the need for new copper mining, while ensuring that it does not pollute the environment. It is equipped with an advanced pulse dust removal system that effectively collects all dust generated during the recycling process, creating a clean and healthy working environment. Maintenance of the dust collection system is simple – just clean the dust bag regularly to keep it running smoothly.

free quote

If you need to process a great number of cables and have a stable source of waste cables, and if you are looking for an affordable recycling solution that is high-efficiency and easy to operate, our BS-A1300 and BS-A1100 copper shredders are the best choice. Get in touch with us, and we will be happy to help you.

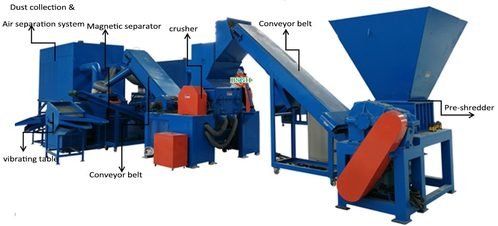

structure of industrial copper cable shredder machine

Our cable shredder mainly comprises the following parts: pre-shredder, main crusher, conveyor belts, air separator, vibrating table, magnetic separator, dust collection device, and electric cabinet. Their functions and working steps are on the right

The Functions of Each Part Are Below:

The cable shredder’s first step is the pre-shredding process. It can shred the waste cables into 6-15cm to be convenient for the next step. This useful device effectively reduces the workload of the main crusher to increase the copper wire shredder’s overall processing capacity, reduce blade grinding, and make the machine more durable. The pre-shredder of BS-A1300 is our special design, which is unique in the world.

The most important step in the cable recycling system. It can process scrap cables into 3-5mm mixture of metal granules and plastic granules. Our main crusher has 48 movable blades and 6 fixed blades, and driven by a 110kw motor, making it very powerful.

The conveyor belt connects all parts of the machine. It can convey raw materials to various parts of the machine, reducing the need for manual operation.

The first step of the separation system, also the most advanced technology in the industry. It uses the difference in weight between metal and plastic to extract metals such as copper and aluminum.

The second step of the separation system, it uses the difference in vibration frequency of the two materials to sort, and then you can get 99.99% copper granules from the mixture. Only China’s cable shredder is equipped with small vibrating tables, while our small vibrating table is the most accurate and durable among them.

Magnetic separator is an essential auxiliary equipment for processing iron-containing cables. It separates iron from all mixtures to ensure that the final product is 100% pure copper or aluminum.

The dust collection device will continuously collect all dust from the recycling process, allowing our cable shredder to meet the environmental standards of all countries.

The electronic control system is used to control the linkage, single action, overload alarm, etc. of each component of the cable shredder, as well as to diagnose the operation of them.

Hydraulic pre-shredder - the unique design in the world

The pre-shredder used in BS-A1300 industrial cable shredder is specially designed by BSGH Granulator. It has the characteristics of high efficiency, high torque, reliability, etc. It is the best partner to help you carry out large-scale cable recycling operations.

- Single shaft design,:with square blades to hook the material, so it can be fed continuously by forklift, which minimizes the risk of getting stuck due to overloading in the crushing chamber.

- It can pre-shred waste cables into 6-15 cm long strips, smaller than the 5-25 cm strips produced by dual-shaft shredder, making it easier for the main crusher to process.

- To solve the problem that the single-shaft shredder cannot hook the wire when processing relatively hard cables, we designed a hydraulic auxiliary pushing system to prevent the machine from idling.

- We have upgraded the hydraulic pushing system. The ordinary pushing system adopts the horizontal pushing method. When there is not enough material in the crushing chamber, there may be empty crushing. However, our hydraulic pushing equipment adopts pushing from up to down, ensuring that the waste cable can be pushed to the blades every time the pusher is extended, and the hydraulic rod has a fast pull-back speed, which effectively reduces the gap time and improves the crushing efficiency.

BSGH Granulator - Your reliable partner in china

With more than 25 years of experience, we are the earliest manufacturer of industrial cable shredder machines since 1995 in China.

Our machines are exported to 80+ countries and regions in the world.

We have established friendly and mutually beneficial cooperative relations with more than 100,000 customers.

Our market share in China has reached 70%~80%.

What services can you get from BSGH Granulator

Professional One Stop solution Service help you handle recycling problems

BSGH Granulator has been a trusted name in the copper recycling industry for nearly 30 years, with extensive expertise in manufacturing and selling cable shredders. Our dedicated technical team is committed to developing and refining cable recycling technology to meet diverse production requirements, helping customers efficiently recover valuable materials and maximize profits.

High-quality machines

We are a high-end copper recycling machine brand with a market share of over 80% in China. We only provide truly high-quality cable shredders, they have precise recycling technology and stable operating systems to continuously create value for you. They perfectly combine reasonable prices and excellent quality to provide you with the most valuable recycling solutions, achieving a win-win situation of low cost and high returns.

Flexible customize service

At BSGH Granulator, our expert R&D team excels at creating customized solutions tailored to your specific needs. Simply send us pictures of your raw materials along with your special requirements, and we will design a flexible solution to meet your exact demands. Whether it’s the blade material, screen material and size, voltage, or machine color, we offer fully customizable options to ensure your satisfaction.

Professional service team

Before sales, we provide the most suitable model selection suggestions, customization services, and help you complete the ordering process so that you can have a smooth shopping experience. During sales, we support you in designing machine placement plans for free and provide machine installation and debugging methods and worker training. After sales, we provide a 12-month warranty and lifetime online quick response service.

Good Feedback

As the industry’s leading brands, our customers are all over the world. Our main overseas markets are concentrated in the United States, South America, Europe, Thailand, etc., and the customer repurchase rate has reached 60%. There is no doubt that our cable shredder has also been widely praised by overseas customers. The following is the feedback from some customers.

Not only does the company do good work, but they also do it with good people. Whenever we are inquiring machinery, they are always ask our requirements, recommend facility and professional in reviewing our needs.

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

We have used BSGH Granulator brand machinery 8 years, and each time ,I have new requirements, we can always message Hannah for quick, efficient service. we are been serviced well in professional machines, such as Copper wire chopper and radiator peeler, we are very happy that we soon take up the recycling market in America.

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

When equipment are scheduled and confirmed, phone conversations ,face to face video call are always friendly and courteous. BSGH Granulator company is without doubt a five-star operation!",I am proud of working with BSGH company !

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

FAQ

Yes, regular lubrication of the machine will help keep the machine running at high performance and extend its life.

Our machines can provide stable performance for more than ten years under normal use and regular maintenance, making them your best choice.

Yes, you can rest assured. All machines of BSGH Granulator are CE certified.

No, the small volume copper and aluminum weight difference is so small that the cable shredder cannot separate them cleanly. When you need to process both copper and aluminum wires, put them into the machine separately.

Our industrial cable shredder machine can process aluminum cables, copper cables, rubber wires, soft wires, armored cables, car loom wires and so on.

When the blades become blunt, you can remove and grind them before continuing to use them. When the crushing effect becomes poor, please manually reduce the distance between the moving blades and the fixed blades. When the distance has been adjusted to 0 but still cannot achieve the ideal crushing effect, you need to replace the blades.

Lets Tell Us About Your Shredder for scrap cables Needs

Please let us know what you need from cable Shredders. We’ll work to come up with options that will meet your needs.

- Whatsapp/Viber: 008613772508206

- Email: coppergranulator@bsghrecycling.com

- Website: https://bsghgranulator.com/

industrial Cable Shredder video

Related Product

If you are a small recycling plant or a medium-sized scrap yard, we also have many small cable shredders and medium-sized cable shredders for your choice.

-

Large Capacity Industrial Copper Cable Granulators for Sale BS-F3000

Read more -

BS-F1000 Copper Wire Granulator with 1T/H Capacity from China

Read more -

400~700KG/H Hot Selling BS-N130 Cable Shredder Machine for Sale

Read more -

BS-N125 Copper Wire Recycling Machine for Scrap Cables

Read more -

Best Price BS-D65 Electrostatic Separator Copper Wire Granulator for Sale

Read more -

Best Cost Performance BS-D60 Copper Wire Separator Machine in Selling

Read more -

BS-D30 Wire Grinding Machine with 300KG/H

Read more -

Affordable BS-D85 Copper Wire Crusher Machine With Electrostatic Separator For Sale

Read more