In early March, an Iraq customer visited our One-Stop Recycling Solution website. He discovered that our company offers a comprehensive range of metal recycling machines, perfectly suited to his needs. After reaching out to our sales manager for purchasing advice, we learned that he owns a major recycling company in Iraq, ranking among the top 5. His business includes 6 processing plants, specializing in recycling waste wires, household appliances, manufacturing scrap, and scrapped vehicles, requiring equipment to process a variety of scrap metal materials.

Transaction Details

Based on his requirements, our sales manager recommended the following five machines:

Additionally, we suggested that to further improve his recycling efficiency, he could purchase a forklift and excavator to enhance loading speed and reduce labor costs. The Iraqi customer subsequently ordered seven machines in total in August. From the deal to the machine is finished production takes about 2 months, after all payments arrive, we arrange shipping and all documents to deliver the machines to the customer’s port, and at the end of July, all machines arrive customer.

Setup and Performance

After transporting the machines to his industry, the customer eagerly tested their performance. As the machines were mostly assembled in advance, it only took one hour for a simple installation and connection to the three-phase power supply.

Following his initial tests, he remarked,

“I am completely amazed by the performance of your machines. They are not only beautiful pleasing but also exceeded my expectations in functionality. I consider this a highly successful partnership.”

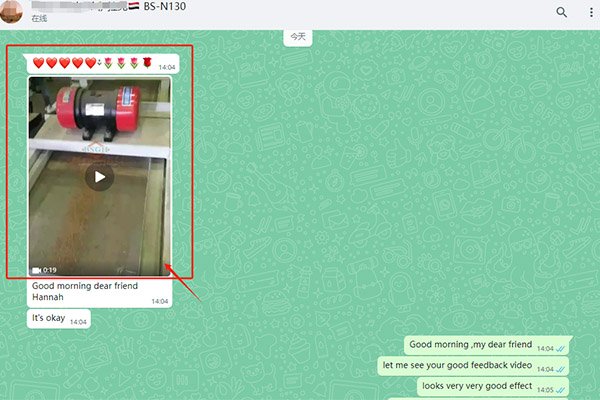

The following is the video of the copper granulator machine working that was sent by Iraqi customers.

BS-N130 Copper Granulator

After half a day of remote training from our technical engineer, the customer’s operator was able to control the machine for processing scrap cables by following the manual. The BS-N130 copper wire granulator was highly automated: operators simply fed automotive wires and other cables into the pre-shredder, and in one hour, it processed 700 KG of scrap cables. The air separator and vibrating table system could efficiently separate the materials, producing clean plastic and 100% pure copper.

Wire Stripping Machine

For large cables not suitable for the BS-N130 copper granulator, such as submarine or high-voltage cables, the customer useed the BS-AC120 wire stripping machine. This machine upgraded casters for easier installation and movement. The worker placeed a 73mm high-voltage cable into the entry hole, and the double-layer upper and lower blades stripped the plastic exterior within 10s. The BS-AC80 wire stripping machine, also purchased by the customer, features similar upgrades, with improved frame blades to handle soft and shielded wires more effectively.

BS-160T Metal Baler Machine, Forklift, and Excavator

The customer used the baler machine alongside the excavator and forklift. One operator loaded scrap steel pipes and plates into the metal baler’s feed port using the excavator, while others operated 160T metal compress and packaged the scrap. Designed with a fully automatic system, the machine quickly produced solid, compact bales under 1 min. Finally, the forklift transported the product to speed up workflow and save labor costs.

When metal plates was too big for the metal baler, the AS-315T alligator shear machine was used to cut it down to size. The machine smoothly cut through big steel plates and includes overload protection to reduce downtime.

Customer Feedback

The day after receiving the machines, our Iraqi customer shared feedback on their performance. He noted that the copper granulator is easy to operate, fully automated, and produces 100% clean copper. The metal baling machine creates solid, compact bales without requiring complex operation, and the wire stripping machine handles large cables smoothly with excellent noise control. The alligator shear, forklift, and excavator also performed well, significantly enhancing the efficiency of his entire recycling operation.

Why Choose BSGH Granulator

Factory-Direct Supply: All machines are manufactured at our factory in Taizhou, Zhejiang, China, eliminating middleman costs and providing significant savings.

Professional Team Support: From pre-sales to post-sales service, our team delivers knowledgeable assistance, offering tailored recycling plans and solutions for any issues.

Quality Focus: We prioritize machine quality over sales volume, employing mature manufacturing techniques and high-quality materials, ensuring each machine meets high-performance standards.

Global Recognition: BSGH has established a solid overseas market in the USA, UK, Italy, Thailand, and more. Our machines are recognized as cost-effective choices comparable to European standards.

Contact US

For any scrap metal recycling equipment needs, feel free to contact us. BSGH Granulator offers exclusive recycling solutions. We look forward to your inquiry!

- Email: coppergranulator@coppergranulator

- WeChat/WhatsApp/Viber: +86 13772508206

- Website: www.bsghgranulator.com