High-efficiency large Copper Granulators Manufacturer

• leading efficiency in the copper recycling industry

• Far exceeds the service life of similar machines

• With the most advanced airflow sorting technology, the separation rate is 2% higher than other machines.

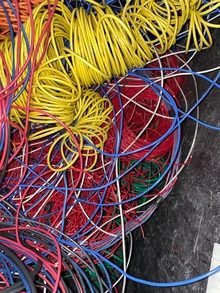

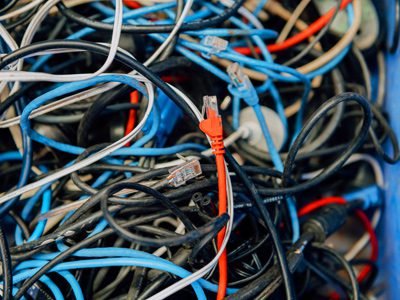

• The processing range covers almost all types of cables

• Your best large mature copper granulator recycling solution provider

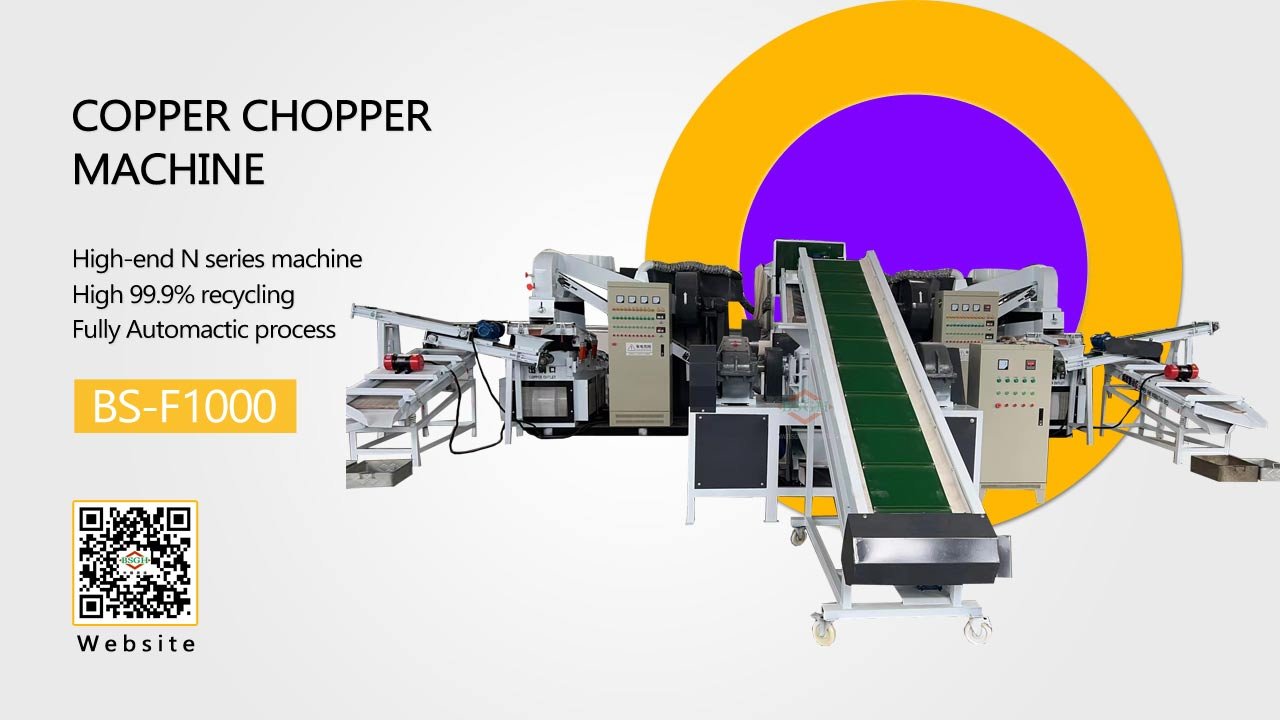

Top large copper granulators from

BSGH Granulator

BSGH Granulator is a global leader in copper recycling machine research and manufacturing, our large capacity copper granulators stand out in the industry with their superior quality, performance, and processing capabilities. Among them, large granulators represent the pinnacle of our innovation, providing excellent results for recycling of various scrap wires and cables, our large granulators are mainly in N series.

Our large granulators excel at processing scrap cables into high-purity copper granules and plastic granules, better for cables with a diameter of less than 30mm. If you process a large amount of scrap cables and have a stable supply source, we strongly recommend our large copper granulators. They are designed to improve your production efficiency and maximum profitability, providing strong support for your recycling business.

large granulators Machine Gallery

Onpage Catagories

Website Catagory

Hot-selling big copper granulators

BSGH Granulator has specially designed several large copper granulators, which are comparable to the quality of top European brand machines, and more competitively priced. You can choose according to your waste cable type and quantity, or you can contact us directly and send us photos of your waste cables for better recommendations.

- More than 20 models for you to choose from

- Processing capacity from 700KG/H-2000KG/H

- Large granulator price from USD 29,999-USD 800,000

- Hot sales in the United States, the United Kingdom, Thailand, Chile, Australia, etc.

- All of our machines have passed CE certification

Case Video

Our big copper granulators are widely used domesitc and overseas, as a superior copper granulators manufacturer, all our machines have passed CE certification and will go through strictly test before shipment. So no need to worry about the machines quality.

And we have many testing videos to let our customers familiar with machine below, it will surely help you a lot, quickly click!

Playlist

3:40

0:16

more video for our customer, if you want to see, pls scan QR in right

- All videos are come from real customer feedback.

- Video on youtube is only parts of our video

BSGH Granulator Youtube QR code

explanation of

large copper granulators function

Main parts

Main Crusher

The large copper granulators main crusher are bigger than others similar middle or small machine, plays a critical role in the cable recycling process with bigger process capability, it also crush scrap cables into 3-5mm copper-plastic mixtures.

• It adopts advanced crushing technology and an efficient power system, supports the rapid crushing of materials, has a good crushing effect, and is not easy to get stuck.

• The blade is made of 96si or SKD-11 steel with high hardness and wear resistance, which can easily complete the crushing task. Even if the blade becomes dull after a period of use, it can be disassembled and sharpened before continuing to use.

• The thickened body design greatly enhances the load-carrying capacity, even if a large amount of scrap cables enter, it will not cause a serious impact on the machine.

Air Separator

For some large copper granulators the air separator are same, some not same, also have bigger size, different model have standard systems.

• The first step of the separation system, preliminarily separate the copper-plastic mixture.

• It uses advanced airflow sorting technology, using wind power to separate heavier copper from lighter plastic.

• The screen adopts a four-layer structure design, made of galvanized sheet, a wooden frame, and two layers of high-quality 304 stainless steel, with high separation accuracy and durability.

Small vibration table

No matter big copper granulators or small or middle, the small vibration table are same size.

• It performs secondary separation of copper granules and plastic granules, ensure you can get 100% pure copper.

• It uses the different vibration frequencies of the two substances to efficiently separate copper and plastic.

• The small vibrating table sieve is made of 304 stainless steel, with precise separation, stable operation, and strong impact resistance.

Optional Auxiliary Equipment

Pre-shredder

For large copper granulator shredder, we have standard one, but if you have much qunatity material, I recommend you to buy bigger shredder.

• Before entering the main crusher, the waste cables are pre-shredded into 5-25cm long strips.

• Adding a pre-shredder to your copper granulator can not only greatly speed up the recycling process but also protect the main crusher blades and extend the service life of the machine.

• High capacity dual shaft shredder, can be used as a pre-shredder to pre-process various waste cables, and can also shred radiators, tires, car engines, small appliances, and other materials as a single machine.

Conveyor Belt

Large granulators all parts will be connected by various conveyor belt.

• Conveyor belts can help you simplify operations by conveying scrap cables to each part of the machine, achieving fully automatic production and reducing the need for manual labor.

• Providing a consistent and even feed rate helps prevent machine overloading and ensures optimal performance of the granulator.

Storage transfer device

• Storage transfer device is usually placed between the pre-shredder and the main crusher for large granulators. It can store pre-processed materials with a capacity of about 500KG.

• In addition to the storage function, it also has a feeding function. The bottom of the device is composed of conveyor belts, which can evenly feed the materials to copper granulator.

Electrostatic separator

• If you need to process a lot of fine wires with a diameter of less than 0.5mm, we strongly recommend that you purchase an electrostatic separator.

• Electrostatic separator is placed at the plastic outlet to separate the processed materials again, extracting the lighter copper that cannot be separated by air separator, effectively improving the recovery rate.

Magnetic Separator

• Magnetic separator is an essential auxiliary device for processing iron-containing cables. It can absorb all magnetic substances - iron from the mixture so that the final copper particles remain pure. • We mainly have two types of magnetic separators: belt magnetic separators and double-layer iron magnetic separation machines.

ask more large Copper Granulators details or different models from bSGH team

which kinds of wires can large

granulator machine process?

For big used copper granulator machine, there’s no limitations for the scrap wire, almost all kinds of wire machine can process well.

For jelly cables/glue wires/plug wire/connector cables can basically be handled well, we have special handling methods for these special cable wires, please contact us for more professional solutions!

Raw material

End Products

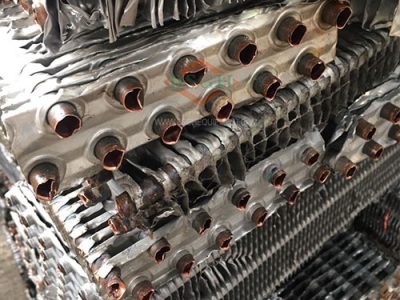

When you process different kinds of cables, you can get copper particles in different forms.

Efficient Recycling for Diverse Materials

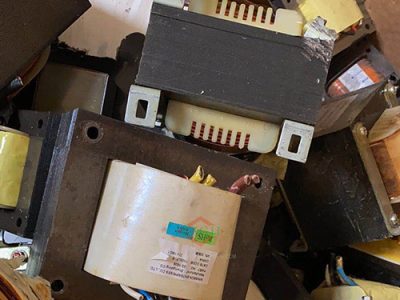

Choosing to buy BSGH Granulator machines, no matter large copper granulators or middle you will get a versatile machine with a strong processing capability and a wide range of applications. It can process both copper and aluminum wires, and has a good recycling effect on both square wires with high copper content and miscellaneous wires with low copper content. In addition to waste cables, the sturdy structure and advanced separation system also support our large granulator to efficiently recycle raw materials such as radiators, small transformers, etc.

Copper Wire

Aluminum Wire

Scrap Radiator

Waste Transformer

Personalized customization service

If you have special types of scrap cables, or if you have special requirements for the machine, we support personalized customization services. Our professional design team will create a unique cable recycling solution for you, customized according to your actual needs. You can also customize key details such as blade material, screen size, machine color, and even add your company logo to ensure that the machine fully meets your business requirements.

Advantages of large copper granulators

latest optimized design

Our machines feature the latest optimized structures, with parts designed for close, logical connections and minimal maintenance needs, significantly reducing downtime. The blade, the only easily worn component, can be sharpened and reused, keeping operating and maintenance costs lower. Furthermore, the fully automatic design requires only 1-2 operators to manage the entire recycling process, helping you save significantly on labor costs.

fully automatic recycle

All of our large models support fully automatic material recycling, and the operator only needs to feed and collect the final product during the whole process. The machine is equipped with an electric cabinet, and the operator can use it to flexibly adjust the wind force and vibration frequency to achieve high-precision separation of different types of raw materials, and can also monitor the voltage level in real time.

High Recovery Rate

With the dual separation system of airflow sorting and vibration separation, our machine can extract the copper from the waste cables to the maximum extent, with almost no copper loss and a recovery rate of up to 99.99%. The final copper granules are uniform in size, smooth and bright, without oxidation, and are 100% pure copper granules that can bring you more profits.

10+ years lifespan

With a simple and sturdy structural design, our machine requires far less maintenance than the market average, but its service life is twice as long as similar machines. Only basic lubrication, regular inspection, and blade sharpening and replacement can it provide more than ten years of stable operation.

Powerful performance

Our large copper granulator represents the highest efficiency in scrap cable recycling on the market today. All processing capacity data displayed on our official website are accurate and achievable, reflecting the machine’s ability to combine high-speed recycling with excellent separation accuracy.

Low Investment Risk

We offer highly competitive pricing, ensuring that the value our best equipment delivers far exceeds its cost. By investing in our machines, you can recover your initial investment within a month and enjoy long-term, stable profits.

Provide High quality Machine for you

About BSGH Granulator

We are proud to be China’s first and largest manufacturer of copper granulators, specializing in their research, design, production, and sales. Our large high quality copper granulators are chosen by more than 100 recycle company every year, combining high efficiency, high recycling rate, and high safety.

Our professional R&D and design teams are committed to continuous innovation, developing high-quality new models, while improving and upgrading the structure of existing models to ensure optimal performance.

In the future, we will continue to be committed to becoming a trustworthy big copper granulator supplier, creating more efficient, energy-saving, profitable equipment to meet the diverse needs of global recyclers.

By simplifying operations and improving productivity, our machines can help customers achieve maximum profitability, quickly occupy the market, and maintain a leading position in the highly competitive recycling industry.

Why choose us

25 years of experience

BSGH Granulator has been in the scrap metal recycling industry for over 25 years. Our professional team can create the best copper recycling solution according to your actual needs, and our professional technical support can solve all your machine-related problems. Choosing us means choosing a reliable business partner, and we will do our best to help you expand your recycling business.

easy operation

Our large granulators are as easy to operate as our smaller models. Designed with user-friendliness in mind, even first-time operators can handle the machine with ease. Our large granulators crafted with maintenance free and long lasting in mind, so it’s your best choice in China.

Sales footprint all over the world

BSGH Granulators are trusted by recyclers worldwide for their superior quality and performance. After comparing with other brands, many customers choose our large granulators for their efficiency and user-friendly design. Our machines have been exported to over 80 countries, earning high praise and repeat cooperation from clients, and establishing BSGH as a leading quality in copper granulator industry.

One-stop service

Before sales, we provide the most suitable model recommendation and personalized customization services. We support free design of factory diagram, circuit, and machine placement for you. During sales, we will update you on the machine production status in time, send you a test video after production finishes, and continue to pay attention to the shipping status until you receive the machine safely. In addition, we provide comprehensive after-sales service to protect your rights.

Professional One Stop solution Service

Quality assurance

We prioritize quality as the most critical factor for our large copper granulators. To ensure the highest standards, we focus on strict quality control during production and comprehensive after-sales support.

- Strict quality control during production

Selection of raw materials

We select high-quality raw materials to manufacture large copper granulators, for example, we use SKD-11 and 96si to make blades, 304 stainless steel to make sieves, and adopt pure copper core motor as the machine motor.

Precision manufacturing process and strict parts testing

We use advanced manufacturing technology and pay attention to every detail to ensure the high precision of each component of large granulators. For example, our blades undergo multiple heat treatments to ensure that they are durable enough while having excellent crushing performance. All parts will be quality inspected before assembly to prevent defects.

Assembling and testing

The components of our large granulator machines are firmly welded together to ensure excellent durability and structural integrity. After production, each machine is thoroughly inspected and tested to verify its performance and reliability. In addition, we provide you with a test run video before delivery so that you can check whether the machine meets your expectations.

- Comprehensive after-sales support

Detailed user guide:

From installation and debugging, operating methods, to machine maintenance, lubrication, and blade removal methods, we provide detailed steps to help you better use and maintain the machine.

One-year warranty

Each large copper granulators has a one-year warranty, during which we provide free repairs and replacement of non-artificially damaged parts.

Lifetime online quick response service

Enjoy 24/7 online support throughout the life of your machine, ensuring a quick response to any questions or concerns.

CE Certificate

Is a copper granulator profitable?

(Profit analysis for big copper wire granulator business)

Absolutely, profitability is influenced by a multitude of factors, which can be simplely expressed in the formula: Profit = Revenue – Costs.

Revenue is contingent upon the quality and output of copper products, as well as the recycling rate and the efficiency of recycling processes. Conversely, costs encompass the initial purchase and subsequent maintenance of copper granulator machines, as well as labor expenses. To maximize profits, it is imperative to swiftly increase revenue while simultaneously curbing costs. Investing in a high-quality BSGH copper granulator machine, renowned for its efficiency and advanced PLC automation system presents a viable solution. Such a machine not only facilitates the production of premium-grade copper products in substantial quantities but also alleviates labor costs.

Many people or customers are having doubts whether cable recycling business is profitable or not? You can refer to below profit analysis of copper wire granulator business, we have conducted a comprehensive profit analysis of the copper granulator, meticulously outlining all pertinent factors, hope it can help you.

- We do as scrap automotive wire, copper content about 55%.

- The smallest big copper wire granulator model ECO1000 for reference.

- Processing capacity about 875KG/H, 8Hours/Day.

| Running Cost Per Day($) | ||||

|---|---|---|---|---|

| Input | Scrap Car Wires | Power Consumption | Workers | |

| Quantity | 7T | 76KW/H*8H=608KW | 2 workers | |

| Unit Price | 4691/T | 0.14 | 21.42/Day | |

| Input Cost | 32837 | 85.12 | 42.86 | |

| Total Cost | 32964.98 | |||

| Income Per Day($) | ||||

|---|---|---|---|---|

| Output | Copper | Plastic | ||

| Quantity | 7*55%=3.85T | 3.15T | ||

| Price | 10008/T | 300/T | ||

| Income | 38530.8 | 945 | ||

| Total Income | 39475.8 | |||

Daily Profit= Daily Income – Daily Outcome = 39475.8 – 32964.98 = 6510.82 ($)

Above table data is provided by our Dubai customer. Due to different countries having different raw materials and final products price, above data is just for reference.

Positive Feedback of Large Copper Granulators

BSGH Granulators are sold all over the world and almost all customers are satisfied with our big capacity machine.

Here are some feedback pictures and videos from our different country customers for your reference.

Feedback pictures

our large granulators always go extra smile

The machine is working as described. We can get pure copper we want by this machine. The supplier constantly support from beginning until we received the machine. Very recommend supplier and trusted service.

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

We received machines, all work perfect!! Thanks for your professional service. You really help me a lot! I also want more other machines, look forward for our more more business!

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

Very professional machine, very profession service, professional sales, I recommend you to consider purchase from BSGHGranulator CHINA famous brand.

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

First of all the quality of machine is very good and I am using from 2015 and you are very professional and cooperative, I love machine and want to do more business with BSGHGranulator.

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

We got the machine and tested the machine yesterday and it works so good. The capacity can meet our needs and the copper granules we get are so clean. Also we are satisfied with service that helped a lot.

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

ECO1000 working well, that’s why order keep coming. The quality is really reliable.

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

The FAQs About Large Copper Wire Granulator Machine

Customers maybe confused when buying a granulator machine, the following are some questions we prepared for large granulator customers who often asked when buying a large copper granulator machine, hope it will help you!

Hi friend, usually we suggest our customers buy more optional accessories such as blades, crusher sieves, vibrating table nets, and air separator sieves.

We provide a 12-month warranty starting from when your machine is installed.

If you have any questions about the machine, we will 24 hours online guide you on how to solve it. What's more, we also provide you with all life spare parts.

If you have any question about machine, we will 24 hours online guide you how to solve. What’s more, we also provide you all life spare parts.

We support T/T 30% advance payment before machine production and 70% balance payment before shipping.

When your machine finishes, we will also send your machine picture and working video for your check.

Yes, of course. When the machine finishes, we welcome you to test the machine on the spot. We also welcome third parties to test machine quality after machine finishes.

What's more, you also can call our customer to know how's machine working. We are an honest and reliable supplier, you can be assured.

Yes, you can get it, no problem.

Our cable granulator machine can process almost all kinds of wires. If the wire you process is like hair, I suggest you add an electrostatic separation device, which can improve the recovery rate of copper.

If the technician comes to your local, you need to bear the fees for Round-trip air tickets, wages, food, and lodging expenses

(1)Air tickets, cost of eating, and hotel fees you can pay directly.

(2)Technical staff salary: USD 100/per day (This big machine may need about 1 week time install, about USD 500-700 . According to the installation time, you can give him cash after installation, no worry)

(3)The cost of applying for a passport by a technician, is about USD 600.

(4)You also can come to China to learn how to install, and maintain the machine after the advance payment. advance payment.

Yes, of course. When your machine finishes production, we welcome your team to check our machine's performance.

Yes, sure. We support dollars, EURO, and RMB. They are the common currency for international trade transactions. You can be assured.

Yes, if you have any questions about installation, our technician will help you.

But normally, Machine transport by the whole set. when you receive the machine, only need to let your electrician help you connect three-phase electricity, then can work the machine.

What's more, we will also send the machine manual for your reference. It's very easy, you can do well. No worry. We will always be with you.y easy, you can do well. No worry. We are always with you.

Yes, sure. Welcome to contact Jocy Whatsapp 86 13772508206 to know how to contact local customers.

I guess maybe you can come to see our customer's machine locally. Contact Jocy at 86 13772508206 to arrange a visit.

Electrostatic separation can increase recycling rates when processing fine wires, usually at the plastic outlet. After the action of electric charge, can get copper particles mixed with a few plastic particles and pure plastic particles.

Put the copper particles mixed with a few plastic particles in the machine to work again, then can get 100% pure copper. particles mixed with few plastic particles in machine to work again, then can get 100% pure copper.

Every country is different. You can use the HS code( 8479899990) to check with your local agent, they are more familiar with this cost.

Yes, of course. We support door-to-door service. You can be assured.

Of course. Our BS-A1100 cable granulator machine with 1.5 T/H uses a forklift to feed cable wire. Contact Jocy Whatsapp 86 13772508206 to know more.