BSGH Granulator

Choose Your Copper Granulator

The copper granulator is a specialized device that is engineered to recycle copper from wire scraps. The principal purpose is to separate useful metal from messy and dirty wires with all diameters. The wires processed will be divided into two materials and be conveyed through two outlets, one is plastic outlet and the other is copper outlet; granules are pure and viable for subsequent recycling or reutilization. In the digital era, the granulator provides an eco-friendly solution to the escalating issue of copper waste. The emergence and development of copper granulator machines is the inevitable result of the scarcity of copper resources, and its widespread application not only relieves resource pressure but also protects the environment, achieving two goals with one machine.

Our expert team has an in-depth understanding of the market, accurately grasps market dynamics, and produces machines that can meet the needs of customers around the world. BSGH Granulator machines have excellent performance, a wide processing range, high throughput, and good durability. This webpage will introduce our large copper granulator machine in detail. If you want to know about machines with other capacities, you can search on our official website.

Certificated Manufacturer

We Focus on Your Copper Granulator Quality

Our dedication to the excellent quality of BSGH Granulator is unmatched. We prioritize quality over selling purpose guaranteeing that each machine we manufacture adheres to both produce standard we made at the beginning and stringent industry criteria set by different countries.

Over the years, our machines have been favored in the international market. Many customers have spontaneously left positive reviews in the comment area, and some customers have established long-term cooperative relationships with us. These are enough to show that the quality of the BSGH Granulator machine is impeccable.

BSGH Granulator is worth of your choice.

How The Copper Granulator Be Manufactured

Step 1 -Raw Material

For raw material: cutting and drilling

Step 2 - Most important step

After the raw materials have preliminary processing, the next step is to take them for heat treatment.

Step 3 - welding

This step is mainly for spare parts welding.

Step 4 - lathe processing

This step is mainly for the main parts of machine processing, such as the main shaft, air separator system shaft, rollers, eccentric shaft, and so on, Its accuracy is very important to the performance of the machine.

Step 5 - spare parts welding

This step is mainly to weld the above-processed parts into semi-finished equipment of main crusher, air separator and dust removal device.

Step 6 - finished products without painting

Welding all finished spare parts into semi-finished products.

Step 7 - install and debug

For semi-finished products, the machine will run for some time meanwhile we will debug and check it making sure it can work at the best performance.

Step 8 - whole machine finished

After Disassembly, we polished and painted it, then assembled and debugged it again. If the machine is proved to operate well, we will deliver it as soon as possible.

project video for different copper granulator

We have various types of copper granulator machines, our machines are made to process all kinds of scrap cable wires, no matter whether your wires are thin or thick, we still have solutions for you to choose from.

Playlist

0:37

0:33

0:23

0:40

0:45

0:40

0:31

0:30

You Deserve The best Performance but the lowest price Copper Granulators From Factory

Leading China Copper Granulators

Can Compete with Euro Granulators

About Copper Granulators Manufacturer- BSGHGranulator

We are a leading copper granulator manufacturer and supplier in China, no matter large or small capacity, we all have. Big copper granulators are very popular in the national market, serving 1000+ customers with great demand.

Since the revolution of granulator technology improved in recent years, our relentless efforts to quality and innovation has propelled us to the forefront of the market. To provide you with the best and wise solutions, we offer a comprehensive range of copper granulator models. Each model caters to specific needs, ensuring you find the perfect fit for your operations.

Why BSGHGranulator

Get Your Cost-effective

Copper Granulators HERE

Industry Expertise & Innovation

BSGHGranulator has perfected copper granulation system over the years. Our team innovates to create copper granulators that are efficient and industry-leading.

Robust Quality Control

We test and inspect every copper granulator. Your product will always be durable, operate well, and produce consistent results due to our quality dedication.

Full Support After-sales

BSGHGranulator values long-term cooperation and high-quality copper granulators. Over the life of your equipment, our unmatched after-sales service includes training, maintenance, and component replacement.

customized/Large copper Granulator for sale

We have many kinds of copper granulator for sale, when you choose copper granulators, you need clear about how many scrap cables have in total? or monthly quantity? If you have many scrap cables regularly, you need big copper granulators, then you can choose from below, according to your wire types and conditions you can choose different configurations. Every one of our models has it’s function and specialty, you also can consult our staffs online.

- Copper granulators for sale price for big capacity: usd48990 to usd156900;

- Processing cable types: car loom wires, telecommunication cables, feeder cables and so on, almost have no requests for cable types;

- Copper granulators hot sales in UK, Canada, USA, Europe.

- Copper granulator models for sale: more than 20+ for big granulators; total 60+ models from small capacity to big capacity;

- Processing capability: 800KG~2000KG/H

- Certificate: All our granulator already pass CE certification;

- Service: copper granulator machine also support customized;

- Industry position: leader in granulator copper fields;

BIGGEST

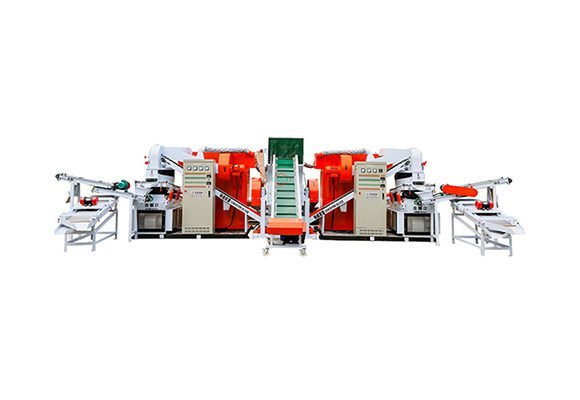

3~5T/H Biggest copper granulators for sale

This machine consists of a big pre-shredder, a big crusher and 4 N series air separator system as the main structure. A powerful crushing system ensures the processing capacity and 4 separation system ensure the pure end products and high efficiency. We provide customized solutions according your situation.

BIGGEST – AMONG STANDARD

BS-F3000 copper granulators for sale

BS-F3000 is the biggest one in our standard machine, it consists of a pre-shredder and one ECO1000 model copper granulator, with 2 small electrostatic separators and 4 small vibrating tables for secondary separation. If you are searching for an efficient, less failure and maintenance, and high-quality solution to elevate your recycling company, the BS-F3000 Copper Granulator is the answer.

BS-F1000 copper granulators for sale

For certain large-scale customers dealing predominantly with square wire and thick wire materials, the ideal choice is the BS-F1000 copper granulator machine. This advanced system is composed of a pre-shredder, the ECO1000 model copper granulator machine, and four small vibrating tables dedicated to secondary separation. Notably, there is no requirement for an electrostatic separator in this setup, making it a streamlined and efficient solution for your specific needs.

N Series

ECO1000 copper granulators for sale

ECO1000 copper granulators consist of one main crusher and 2 air separator systems with 4 small table vibration beds. The processing capacity can up to 1T/H with the most advanced technology, heavy duty but save energy, very suitable for the newer in this fields, because of easy operation and comparatively lower costs.

N Series

BS-N130 copper granulators for sale

Capacity: 400~600KG/H

Structure: Pre-shredder + Main Crusher + Air separation + Small vibration tables

Similar capacity: BS-D80 BS-D85

For different kinds of wires, machine processing capability also not same:

- 4~6 Square cables: 600~800KG/H

- 1.5~2.5 square cables: 400~700KG/H

- For car wire and telecommunication wire, copper content is about 45%~50%, capacity can reach 300~600KG/H

- For complex wire and hair wire, copper content is about 20%~30%, capacity can reach 200~400KG/H.

BS-D85 copper granulators for sale

This model belongs to our D series big copper granulator machine, which aims for the best cost-effective but perfect performance machine. If you think the similar machine in N series higher costs, this machine must be your secondary ideal choice.

- Structure: Pre-shredder + Crusher + Air separator + Small table vibrator + electrostatic separator machine

- Recycling rate: 99.99%

- The capacity also varies for different kinds of cables, similar to BS-N130

- Lower crusher noise.

As you can see, we listed some very popular models of big copper granulator machines above for your reference. Every machine has its features and fits different customer demands. If these machines can’t meet your demands or you have other requests, you can contact us for customized services

We have lots of experience and customer feedback video

News & Case Studies

How to do shredder maintenance?

I. Introduction An industrial shredder isn’t just a piece of equipment; it’s the engine of your profitability. Whether you’re processing scrap metal, e-waste or other

How to choose different types of industrial shredders?

I. Introduction Industrial shredders are a vital tool in many industries today. Whether you’re cutting down bulky waste, recycling materials, or destroying products for security

FAQs

Copper granulators work by shredding scrap and waste copper wires into tiny particles. They effectively separate pure copper granules from insulated wires using a combination of cutting blades and separating processes.

A high-quality copper granulator has a long lifespan, is easy to use, and requires little maintenance. Furthermore, its design should enable a high separation rate, maximizing copper recovery from scrap.

Absolutely. If you have a large amount of scrap copper wire, a granulator can help to speed up the recycling process. This machine not only reduces manual labor, but the recovered copper can also be sold at a profit, frequently more than compensating the initial expenditure.

Cleaning the blades, keeping the separation systems clear of dirt, and inspecting for worn-out parts are all part of routine maintenance. Following the manufacturer’s maintenance requirements can considerably extend the life of your machine.

Yes, they are critical to sustainable resource management. Granulators eliminate the need for mining and the environmental consequences associated with raw copper extraction by reusing copper.