Lifting Electromagnet Manufacturer

The lifting electromagnet is a specialized device that harnesses electric and magnetic properties to raise materials it’s attached to. It’s essential for lifting and transporting ferromagnetic materials in various industries like metallurgy, mining, machinery, shipbuilding, and transportation. Additionally, it serves purposes such as electromagnetic manipulation, magnetic force centering, and fixing bar lengths in certain fields. Because the materials it handles vary, the electromagnet’s structure, magnetic circuit, and manufacturing processes also differ, resulting in numerous targeted product series with specific strengths and capabilities.

About Us

Lifting Electromagnet with different capability

BSGH Granulator is not only produce all kinds of scrap copper recycling machinery, but also serve our customer with peripheral products lifting electromagnetic to increase the efficiency of the machine and facilitate customer operation.

In the realm of industrial operations, the handling and transportation of diverse raw materials present formidable challenges. Many of our clients encounter significant complexities due to the diverse range of raw materials they handle—varying in size, type, and characteristics. Our lifting electromagnets are meticulously designed to specifically address these challenges, providing an effective resolution that minimizes customer concerns and optimizes operational efficiency. By leveraging our technology, clients effortlessly achieve their objectives, efficiently managing the intricacies involved in material handling.

At the core of our mission lies a steadfast commitment to empower our clients across industries. With our specialized electromagnets as the cornerstone, our aim remains unwavering: simplifying the intricate realm of material handling. we aspire to be the driving force propelling our clients toward unparalleled success in their diverse industrial pursuits.

lifting electromagnet types

Electromagnetic lift, with their diverse types, shapes, and configurations, cater to specific applications across various industries. This versatility underscores their effectiveness in meeting industry-specific needs, showcasing the adaptable nature of magnetic technology in fulfilling specialized requirements across sectors.

Scrap metal lifting electromagnet technical datas

There are also have high-temperature types, high frequency types, oval shape lifting electromagnet, Lifting Electromagnet for Billet, Girder Billet and Slab and so on.

Suitable for cast ingot, steel balls, pig iron, machine chips, for various kinds of steel scraps, return scraps, cropping, baling scraps and etc in foundry factories and for iron powder in coal washery. During slag disposal process, it can remove the large size of iron at the initial step. The outlet box has two chambers, an extra thick fender and an anti-twist setting. There are three excitation options: rated voltage DC220V; strong

excitation; over excitation.

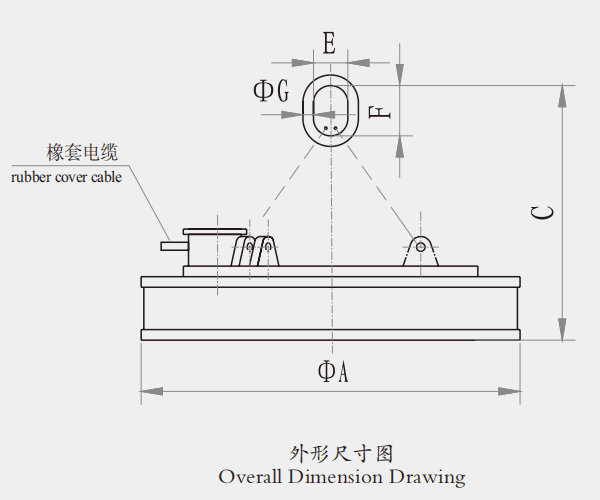

| Model | Cold-state power(KW) | Current(Cold/Hot state) | Weight(KG) | Overall diamension | Lifting Capacity(cold/hot state) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | C | F | E | G | Steel ball | Casting ingot | Turnings | ||||||

| BS5-50L-1 | 2.6 | 11.8/7.7 | 220 | 500 | 700 | 160 | 90 | 25 | 1200 | 220/130 | 80/65 | ||

| BS5-60L/1 | 3.0 | 13.6/8.9 | 320 | 600 | 750 | 160 | 90 | 25 | 2000 | 290/170 | 95/80 | ||

| BS5-70L/1 | 3.3 | 15/9.8 | 490 | 700 | 800 | 160 | 90 | 30 | 2500 | 380/200 | 120/100 | ||

| BS5-80L/1 | 4 | 18/12 | 580 | 800 | 800 | 160 | 90 | 30 | 3000 | 480/250 | 150/130 | ||

| BS5-90L/1 | 5.9 | 26.8/17.5 | 750 | 900 | 1090 | 200 | 125 | 40 | 4500 | 600/400 | 250/200 | ||

| BS5-110L/1 | 7.7 | 35/22.8 | 1100 | 1100 | 1140 | 220 | 150 | 40 | 6500 | 1000/800 | 450/400 | ||

| BS5-120L/1 | 10 | 45.5/29.5 | 1300 | 1200 | 110 | 220 | 150 | 45 | 7500 | 1300/100 | 650/500 | ||

| BS5-130L/1 | 12 | 54.5/35.5 | 1700 | 1300 | 1240 | 250 | 175 | 50 | 8500 | 1400/1100 | 700/600 | ||

| BS5-150L/1 | 15.6 | 70.9/46.1 | 2200 | 1500 | 1250 | 350 | 210 | 60 | 11000 | 1900/1500 | 1100/900 | ||

| BS5-165L/1 | 16.5 | 75/48.8 | 2700 | 1650 | 1590 | 370 | 230 | 75 | 12500 | 2300/1800 | 1300/1100 | ||

| BS5-180L/1 | 22.5 | 102.3/66.5 | 3200 | 1800 | 1490 | 370 | 230 | 75 | 14500 | 2750/2100 | 1600/1350 | ||

| BS5-210L/1 | 28.4 | 129/84 | 4200 | 2100 | 1860 | 400 | 25 | 80 | 21000 | 3500/2800 | 2200/1850 | ||

| BS5-240L/1 | 33.9 | 154/100 | 5500 | 2400 | 2020 | 450 | 280 | 90 | 26000 | 4800/3800 | 2850/2250 | ||

| BS5-260L/1 | 35.6 | 162/105 | 6800 | 2600 | 2100 | 450 | 280 | 90 | 30000 | 6100/4900 | 3850/3600 | ||

| BS5-280L/1 | 39 | 178/116 | 7900 | 2800 | 2700 | 500 | 300 | 100 | 34000 | 7100/5700 | 4450/3400 | ||

| BS5-300L/1 | 41.6 | 189/123 | 11000 | 3000 | 2300 | 500 | 300 | 100 | 39000 | 8350/6700 | 5250/4100 | ||

This electromagnet is designed for standard temperature operations. For specialized requirements such as high-temperature or high-frequency applications, please don’t hesitate to contact us for tailored solutions and further assistance.

features of lifting electromagnet

- Adopt totally sealing structure with good property of moisture-proofing. Non-magnetic protect domestic initiative, stainless steel plate production, magnetism-isolation, wear-resistant and shockproof.

- Overseas technology has been introduced, improved, innovated, as well as get optimum designed by computer to make our products reasonable structure, light self-weight, strong attraction force and low energy consumption.

- The energizing coils have been processed by special technology and thus its property of electrical and mechanical properties are enhanced, Heat-resistant of insulating material reaches grade C and service life is long.

- The rated duty cycle of a normal electromagnet has increased from 50% in the past to 60%, thus working efficiency gets improved.

- Over-high temperature electromagnet adopts unique isolation from heat and radiation, the temperature of attached materials gets increased from 600° C in the past to 700° C, which expands the application range of the electromagnet.

- A full set of auxiliary unit such as Control Cubicle, Cable Reel, etc can be provided as well.

- Installation, operation and maintenance are convenient

How do I choose an electromagnet?

- The specification, tonnage, hoist height, brake type of hook, and capacity. — should be provided.

- Choose normal or high or super-high temperature type according to the material’s temperature. If below 150 ° C choose normal type; between 150° C and 600° C high type; above 600° C but with a limit under 700° C, super high type.

- Duty cycle: when exceeding 60%, choose the high-frequency type.

- When the operation is in liquid, please choose the diving type and provide us with liquid medium and diving depth.

- Please provide geometry parameters (such as length, width, depth, diameter and so on.) and number of pieces or bundles to lift when lifting section material, and sheet material.

- For single unit, choose the control cubicle and other assistant equipment according to consumed power (current); for the combined unit, we need the total amount of consumed power (current).

- Lifting height determines the length of cable coiled on the cable reel. The power of the electromagnet (current) determines the current tolerance of the cable reel. Pieces of the electromagnets and grouping condition determine the number of cores.

Understanding Scrap Metal Lifting Electromagnets

Evolution and Innovation

The journey of scrap metal lifting electromagnets traces back to the 19th century. Initially, basic configurations were used, but technological advancements have led to highly sophisticated models. The evolution has been marked by enhanced lifting capacities and operational efficiency.

How Scrap Metal Electromagnets Work?

These electromagnets utilize electromagnetic fields generated by electric currents. The flow of current through a coil of wire creates a magnetic field. When the electricity is activated, the magnet attracts ferrous materials. Once the current ceases, the magnetic field diminishes, releasing the load.

Advantages in Industrial Applications

Efficiency in Material Handling

Scrap metal lifting electromagnets excel in handling heavy and irregularly shaped ferrous materials. Their magnetic strength ensures secure gripping and transportation, significantly streamlining operational processes.

Safety and Cost-Effectiveness

These electromagnets contribute to a safer work environment by reducing the need for manual handling. Moreover, they minimize material damage, resulting in cost savings by preserving the integrity of transported goods.

Components and Configuration

A typical scrap metal lifting electromagnet comprises a ferrous core, a coil wound around it, and a power source. The arrangement is designed to optimize the magnetic field for efficient material lifting.

Applications Across Industries

Metal Recycling Facilities

Scrap metal lifting electromagnets play a pivotal role in recycling operations. They efficiently segregate and transport metallic waste, contributing to sustainable practices and resource conservation.

Construction and Demolition Sites

In construction, these electromagnets aid in moving heavy steel beams and structures. Similarly, in demolition, they assist in clearing debris by swiftly lifting metal scraps.

Manufacturing and Assembly Lines

Manufacturing units utilize these electromagnets for material handling during various production stages. Their precision and efficiency streamline the assembly process.

FAQ about lifting electromagnet

Scrap metal lifting electromagnets, when used according to safety guidelines, are considered safe. However, caution must be exercised to prevent accidents.

Absolutely! Their magnetic strength enables the lifting of diverse ferrous materials, irrespective of shapes and sizes.

Most commonly, they operate on electricity, but specific configurations can be customized to suit alternative power sources.

Routine checks for wear, tear, and proper functioning are essential. Maintenance tasks might include inspecting the coil, checking connections, and ensuring the power source is stable.

While some variations are designed for underwater use, standard models might face operational limitations when submerged.

Consider factors such as lifting capacity, power source compatibility, and operational environment when selecting the appropriate electromagnet.