I. Introduction

To maximize profits with a copper granulator in 2026, focus on high-efficiency models, proper maintenance, and strategic market positioning. Choose the right capacity for your scrap needs, keep the machine well-maintained, and stay informed about copper market trends to gain a competitive edge.

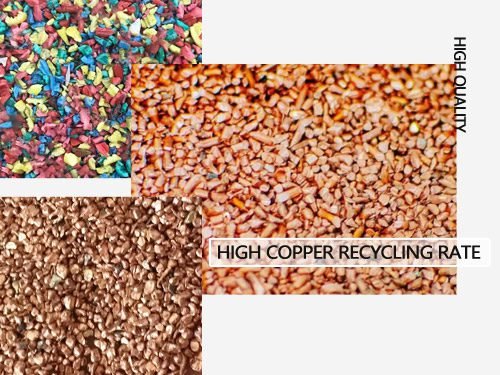

An industrial-grade copper wire granulator efficiently separates copper from insulation layers. If engaged in the scrap metal recycling industry, you must be well aware of the value of copper. However, extracting pure copper from insulated wires isn’t easy—unless you have the right copper wire granulator machine. With the great development of recycling technology, copper wire granulator machines in 2026 will be more intelligent and efficient.

II. Choose the right machine for your needs among such a large market

Before buying a new copper shredding machine, first you should totally judge their types and usages, only then can you make a better choice.

1. Types of Copper Granulators & Their Best Uses

Granulators vary in performance. Generally speaking, they can be classified into various types with diverse features by different standards as follows:

a. Dry-Type Copper Granulators

- No water used–Ideal for high-purity copper recovery

- Lower maintenance–No water treatment needed

- Best for: Medium to large–scale operations with dry scrap

b. Wet-Type Copper Granulators

- Water-cooled processing–Reduces dust and improves separation rate

- Higher purity output–Better for fine copper wires

- Best for: Recyclers needing 100% copper recycled one time

② By Processing Capacity

a. Mini Granulators (<100kg/h) – For small workshops or R&D purposes

b. Standard Units (100-500kg/h) – Most common for mid-sized recyclers

c. Industrial Systems (500-3000kg/h) – Continuous processing for large recycling centers

③ By Electricity Phase

a. Single-Phase–Cheap and for home use

b. Single-Phase–Cheap and for home use

④ By Series in BSGH Granulator

a. Mini Series–Mainly for low budget and small business users

b. D series – Compact and best cost-effective

c. N Series – 100% copper purity and 99.9% separating rate

2. The 5 Critical Purchasing Factors in 2026

In this guide, I’ll analyze the top 5 factors to you before paying for a copper wire granulator in 2026, maximizing your profits for any business size.

① Types of Cable Wire & Processing Capacity

Ask yourself: Which types of scrap cable wire and what amount of processing capacity are required daily?

a. Different types of copper cable need distinct copper granulators.

- To be specific, there is iron inside the wire harness, so it is necessary to equip a magnetic separator machine.

- If the waste wire is under 2mm in diameter, it is better to assemble an electrostatic separation machine.

- If you have armoured copper wire, you can assemble a pre-shredder(there are also different types of preshredders; the following are different types for your reference, if you not know how to choose, then you can contact us for better recommendations) for a thorough crush.

b. The processing capacity makes a big difference on choosing machines.

- Small recyclers → 200-500 kg/hour machines

- Large plants → 1,000+ kg/hour industrial systems

Note: It is necessary to buy a machine with a slightly larger capacity than your current needs for business growth.

② Copper Purity & Recovery Rate

The excellent quality granulator machines can achieve 99.9%+ scrap copper separation rate and 100% clean copper. Key technologies that affect output purity:

a. Airflow separation (removes lightweight plastics)

b. Vibrating screens (filter copper particles and you can get the most of pure copper here)

c. Electrostatic separation (for ultra-fine copper recovery)

d. Magnetic separator machine (for ferrous material recycling)

③ Energy Efficiency & Operating Costs

a. Electricity consumption: Dry types usually use 10-30% less power than wet systems, typically saving 10-30% energy than wet ones.

b. Maintenance costs: Check how often blades need replacement (high-quality tungsten steel lasts longer but too too expensive, normally we use SKD-11 instead).

c. ROI Calculation: Our BSGH Granulator machine at the price of $50,000 processing 400-600kg/h can return on investment in half to one month based on a steady supply of the raw materials.

④ Machine Durability & Manufacturer Reputation

Key Considerations:

a. Hardened steel blades (resistant to wear)

b. Steel raw material

c. 1 years warranty (indicates confidence in product)

d. The production technology is also the most important, to be honest, every manufacturer know how to produce granulator and their technique, but frankly speaking, the machine performance is really different, so thus will have 2 results:

- For pursue quality customers, they buy a good machine and earn more money, meanwhile consider this business is good and can be a long-term business.

- For low price pursue customer, they think all machine are similar and same, they buy the inferior quality granulators, when they use, continous problems will happen and make them feel frustration and down to this industry, such story are always happening among our clients, many low-price pursuit customers always complain about machine quality but can’t do anything about it.

e. Check supplier’s amount of videos.

Note: It’s better to check the supplier machine video: not one but many many different customer feedback videos. This is the most reliable, actually, except BSGH, many others can’t provide you so many videos.

⑤ Environmental Compliance & Safety

Regulations for 2026 are stricter on:

a. Dust emissions (HEPA filters may be required)

b. Noise levels (under 75 dB for worker safety)

c. Wet systems must have closed-loop water recycling to avoid pollution.

d. Safety features: Emergency stop buttons, overload protection and insulation guards.

III. How to Get the Best Deal in 2026

a. Request a demo – Test the machine with your scrap.

b. Compare quotes – FOB (factory price) vs. CIF (shipping fee included).

c. Financing options – Leasing or pay-per-ton models reduce upfront capital costs.

IV. Conclusion & Next Step

In 2026, selecting the right copper granulator is crucial to profitability. Businesses should match machine type to their scrap scale, aim for 99%+ copper recovery, and reduce operating costs through energy-efficient designs. Key factors include throughput, power consumption, and maintenance requirements, alongside investing in durable machines from reputable suppliers. At the same time, ensure compliance with safety and environmental standards and align with market trends. By balancing efficiency, purity, cost, reliability, and strategic positioning, recyclers can boost output and achieve sustainable long-term profits.

Find the right copper wire granulator machine in BSGH granulator ! Get the best deal and maximize your profits in 2026!