Mini Metal Baler Machine

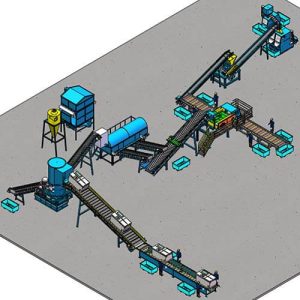

BSGH Granulator small or mini metal baler machine is the best solution for entry-level waste metal baling or small-scale metal recycling companies, characterized by:

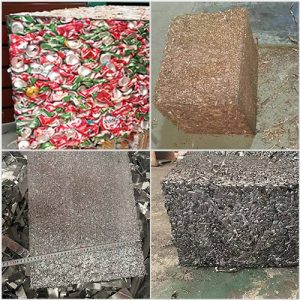

- Perfect in handling: lightweight metals, metal chip or metal turnings scraps, aluminum cans and other low-density metal materials.

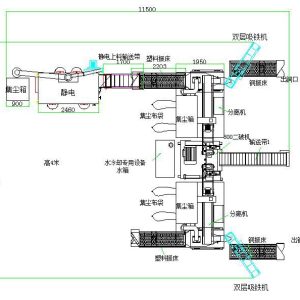

- Small footprint: Low requirements for factory area, more flexible for installation.

- Hydraulic system control: Stable performance and easy to maintain.

- Low price with the good quality for mini metal baler machine.

Features of mini metal baler

BSGH Granulator’s small metal baler enables to process various light metal waste, mainly suitable for individual business who just stepped into metal recycling or small scrapyard. Besides affordable price, the reason why our home use mini metal baling machine stands out in the fierce Chinese recycling market lies in their superior features:

- Removable lock hole for easy replacement;

- High-pressure pipe material: seamless steel pipe + high-pressure resistant steel wire tube;

- The lock slider head and chamber inner walls are lined with hardened wear plates;

- Baler body material: Q235B;

- Water cooling to guarantee a better operation.

- Have multi models for you to choose from for different pressure.

- Support to custom the chamber size, bale size and tonnage.

If you are unsure which to choose, don’t hesitate to get in touch with us and send pictures of your raw materials, then we will recommend the most suitable machine for you.

Hot sale mini metal baler machine worldwide

The BSGH Granulator R&D team has developed a full range of metal baling machines that help you cut storage and transportation costs by up to 80%, making your recycling business more efficient and more profitable. For mini metal balers, we have selected our three most popular models for your reference—each with the same core specifications but different configurations to meet your specific needs.

- Working pressure: 20-25MPa

- Voltage: 380V/50HZ

- Rated pressure of piston pump: 31.5MPa

- Has four hydraulic cylinders.

60T mini metal baler

Optional: You can choose 3 different chamber size.

- Small chamber size: 500*400*250MM

- Medium chamber size: 600*500*350CM

- Large chamber size: 900*700*350CM

- Bale size: 300*150*150mm

- Power: 11KW

- Single cycle time: about 50s

Optional: You can choose small or large chamber size.

- Small chamber size: 1000*800*350MM, bale size: 400*200*200MM

- Large chamber size: 1200*700*450CM, bale size: 400*250*250MM

- Power: 15KW

- Single cycle time: about 60s

Feature: Standard baler machine have one baling chamber size, it is large among small metal balers.

- Chamber size: 1200*800*450MM

- Bale size: 500*300*300MM

- Power: 18.5KW

- Single cyclSingle cycle time: about 70s

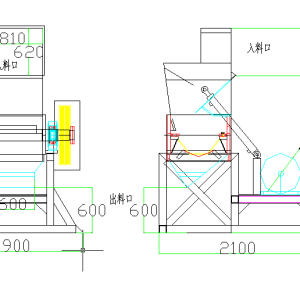

- Main unit dimensions: 3.3*2.3*1.8M

- Hydraulic station dimensions: 1.3*0.7*1.3M

How does mini metal baler work?

Experience the performance of our 60T horizontal metal baler, designed with a compact feeding chamber and exceptionally smooth operation. Simply switch on the machine, load loose aluminum chips into the hopper, adjust the control lever—our hydraulic mini metal baler will compress the material into high-density blocks in under one minute.

The final 30 × 15 × 15 cm bale significantly reduces storage space and makes transportation easier, helping you cut handling and logistics costs. With minimal manual intervention required, the entire baling process stays efficient, reliable, and consistent.

Interested in seeing how other models perform? Click the button below for more demo videos.

advantages Of mini metal baler

Fast Cycle Time

Our small hydraulic metal baler is able to press waste light metals with fast cycle time, only needs less than 70s, suitable for multi-frequency and small-batch baling work.

High-Durability Cylinder

The hydraulic cylinder is made of chrome-plated material undergoing quenching and tempering heat treatment, and have a solid piston rod, both keep our mini metal baler an exceptional strength, wear resistance, and long-term reliability under constant high pressure.

Hardened Locking Head

The locking head is quench-hardened to achieve a high surface hardness, significantly extending its service life by resisting deformation and wear, even under heavy, repeated use.

easy to operate

Operators can directly control the entire hydraulic system by adjusting simple three hydraulic levers, requiring no special training, even beginners can operate, saving your labor cost.

Raw material and end product

Mini hydraulic metal baler from BSGH Granulator aims at compressing lightweight materials such as metal chips and other low-density materials into solid, high-density bales, especially favored by limited budget recyclers from over 80 countries worldwide.

Personalized customization service For mini metal baler

BSGH Granulator offers a full range of metal baling solutions tailored to your specific materials, including metal balers, car balers, aluminum can balers, and more. We also provide free customization—from core functions to exterior design— giving you greater flexibility to meet your production needs. Our machines are widely trusted and highly popular in both the U.S. and European markets for their reliability and performance.

1. We provide two types of small baler for metal scrap: horizontal metal baler and vertical metal baler.

Vertical metal baler: Known for small footprint, relatively tall, fit for manual or simple lifting feeding material.

Horizontal metal baler: With a high degree of automation and a wide processing capacity, it is the ideal solution for producing larger, denser, and more uniform bales—dramatically boosting logistics efficiency and reducing overall handling costs. Besides, this types of baler can be divided into three bale ejection methods:

- Front-Out Baler: Our most popular model for high-demand recycling operations. With side ejection and maximum compression force, this structure produces the highest-density bales and runs with outstanding stability. Available across all tonnages, it’s the preferred choice for large metal recycling centers that need durability, speed, and long service life.

- Turn-Out Baler (Turn-Over Ejection Type): Designed for efficiency in compact spaces. The bale is rotated and discharged downward, normally machine height stay under 1 meter. Most models below 250T, making it the ideal mini baler for ferrous metal chips and small-volume recycling. Delivers dense bales while keeping the machine footprint small and easy to operate.

- Front Push-Out Baler (Front Ejection Type) A cost-effective entry solution for light materials. With front ejection and a single compression, it offers faster cycles and the lowest price range, supporting tonnages up to 160T. Perfect for aluminum cans, lightweight scrap, and facilities seeking maximum output at minimum cost.

What Our Clients Say

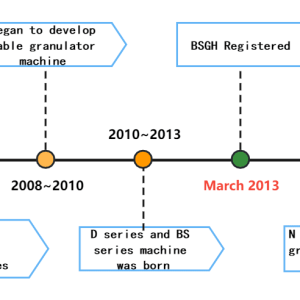

Although the small metal baler is our newest design, it has catered to a large number of customers around the world, we have received good comments from their feedback, inspiring us to move forward and continually engineer more metal balers to fit your varying needs.

FAQ about mini metal baler

What is the block weight of each small metal baler?

The block weight of each small metal baler is different. We have specific data, if you need, just feel free to contact us.

How long does your small metal baler take to finish one compression cycle?

About 60 seconds and smaller models are slightly faster than larger ones.

Are the bales of mini metal baler all square?

Normally, the bales is square because it can save your space and convenicent for storage to the maximum extent, of course, if you need special shape bale, just consult us for more.

How much does a mini metal baler cost?

Generally speaking, the price is rely on your baler configuration, our smallest metal baler only needs 5999USD, worth your investment.

How Can I choose the most suitable mini metal baler?

Small metal baler mainly differs in hydraulic pressure, chamber size and bale size with processing materials, so you can send us your raw material picture, we can figure out the optimal one for you.

I'm really concerned about the maintenance, is it easy to maintain the small metal baler?

Do not worry, our small metal baler can serve for over 10 years under normal use, you only need to inspect the oil tank full of enough oil, if any problem occurs, our 24/7 online sales staff will offer you a professional solution till problems are solved.