New Energy Vehicle Motor Recycling Machine Overview

With the gradual development of the car industry, the number of new energy vehicles is also increasing. Most new energy vehicles adopt permanent magnet synchronous motors, which contain copper windings in the motor stator and high-value strong magnets in the motor rotor. Recycling these copper windings and strong magnets when the car is scrapped is not only a recycling of metal resources, but also can create high profits.

The new energy vehicle motor recycling machines are used to recycle new energy vehicle motors. They are mainly divided into motor stator recycling machine and motor rotor recycling machine. The new energy vehicle motor stator recycling machine can cut one end of the copper winding and grab the copper winding from the stator. The motor rotor recycling machines first remove the shaft of the motor rotors, and then heat the motor rotor to effectively recover the strong magnetism in the rotor. At present, the new energy vehicle motor recycling machine is suitable for major new energy vehicle manufacturers and recycling plants. It is a simple and effective solution for automobile motor recycling.

Your Leading New Energy Vehicle Motor Recycling Machine Supplier

BSGH Granulator is the first manufacturer in the market to develop and manufacture machines for recycling new energy vehicle motors. At present, new energy motor recycling machines on the market have not yet developed to maturation. However, BSGH Granulator, with more than 25 years of industry experience and expertise, and the most advanced motor recycling machine manufacturing technology, was the first to overcome the problem and manufacture the perfect new energy vehicle motor recycling machine. In addition, we also provide a variety of scrap metal recycling machines.

Comprehensive product line

Complete specifications and powerful functions. BSGH Granulator provides different types of car casing shredders, car balers, car engine shredders and other machines to meet your needs for recycling various car parts. No matter what raw materials you need to recycle, you'll find the right machine at BSGH Granulator.

High cost performance

Our machines have both top quality and low price. Choosing us, you will buy machines with quality comparable to top European brands at a competitive price.

Worldwide Shipping

Our products support worldwide shipping. No matter where you are, we can ensure that your order is delivered quickly and safely.

Thoughtful service

BSGH Granulator always puts service in a great important position. We believe that only by protecting the rights of our customers and providing them with satisfactory services can let our customers think of us firstly when choosing scrap metal recycling machines.

The best new energy vehicle motor recycling solution

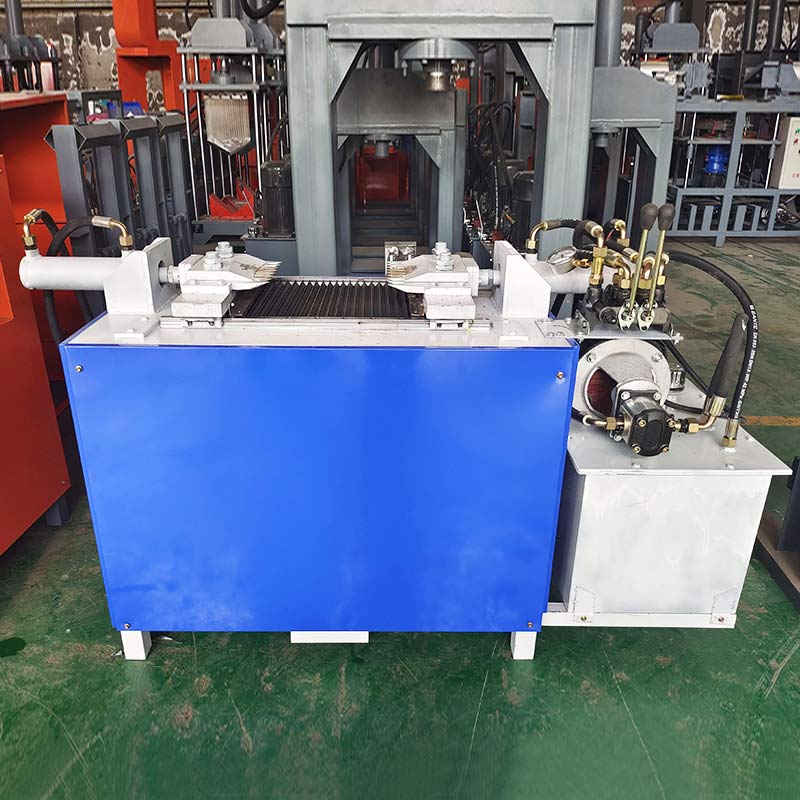

New energy motor stator recycling machine

Since new energy vehicle motors have different structures and copper winding methods from ordinary motors, it is difficult to recycle them well using ordinary motor recycling machines on the market. In order to meet customers’ needs for recycling copper windings in new energy vehicle motor stators, BSGH Granulator developed this new machine with more power. It can efficiently separate the entire copper wire windings in the scrap new energy car motors.

BSM-90 Motor Stator Recycling Machine

Power: | 5.5KW |

Voltage: | 380V/50HZ,3Phase or Customized |

Motor speed: | 1400r/m |

Pump: | Gear pump G625 |

Cutting knife width: | 95MM |

Cutter Stroke: | 10CM |

Cutter Cycliner Inner/Outer Diameter: | 63/75MM |

12 Jaw Range: | 75-120MM |

16 Jaw Range: | 120-180MM |

Features of new energy motor stator recycling machine

-

High Efficiency

The machine is equipped with a cutting part and two pulling parts, capable of processing your new energy vehicle motors with high efficiency.

-

Safety And Security

The machine adopts a foot control switch to ensure the high safety.

-

Powerful Claw Clamp

Twelve-Claw Clamp and 16-claw clamps,a jaw specially designed for processing special motors.

-

100% Recycle

No copper loss, it can completely recycle the copper windings in the motor stator.

Contact us for

more machine information

If you have scrap motors from new energy vehicles that need recycling, don’t hesitate to send us your inquiry today! Our dedicated team is passionate about delivering the best recycling solutions to your specific needs. Contact us now and experience top-notch service and efficiency!

New energy motor rotor recycling machines

New energy vehicle motor rotors contain strong magnets, which are substances with high recycling value. Recycling the strong magnets in the motor rotor can bring you high economic benefits. Recycling new energy vehicle motor rotors mainly requires two machines:

Motor shaft pulling machine

The motor shaft pulling machine is mainly used to remove the shaft from the motor rotor. You only need to fix one end of the motor rotor on the machine, and the machine will automatically complete the process of removing the shaft.

- Power: 5.5KW

- Size: 2720*950*930MM

- Weight: 630KG

- Voltage: 380V/Customized

- Diameter: More Than 10mm

- Warranty: 1 Year

The car motor rotor heating machine is mainly used to heat the motor rotor after the shaft is removed. After being heated by the machine, you can manually remove the strong magnets in the motor rotor.

- Motor power: 3KW

- Host Size: 650*510*920MM

- Host Weight: 110KG

- Gas Station Size: 560*460*800MM

- Gas Station Weight: 55KG

Features of new energy motor rotor recycling machine

-

Compact Structure

Our new energy motor rotor recycling machine has a compact structure and saves space.

-

Performance Security

The shaft removal machine adopts a hydraulic system, which can remove the shaft of the motor rotor more efficiently and maintain stable performance during long-term operation.

-

Efficient Heating Technology

The heating machine supports rapid heating of motor rotors, and the processing time of one motor rotor is about 10 seconds.

-

Advanced Smoke Structure

The heating machine is equipped with the most advanced smoke exhaust system. It can discharge harmful gases in time and ensure the health and safety of operators.

free quote new energy motor rotor recycling machines

What valuable resources can be recycled in new energy vehicle motor rotors? How to recycle strong magnets to maximize benefits? If you don’t know, please contact us at any time.

How do our new energy car motor recycling machines work?

New energy motor stator recycling machine

New energy motor rotor recycling machines

- First, after removing the motor casing, use the cutting part of the machine to cut off the copper winding at one end of the motor stator.

- Then put the motor stator into the pulling part, and the jaw will automatically grab the copper winding and pull it out completely.

First, fix one end of the new energy motor rotor on the motor shaft pulling machine. After starting the machine, the motor shaft pulling machine will automatically push the shaft out from the rotor.

Second, heat the motor rotor without the shaft with car motor rotor heating machine, and finally you can manually recycle the high-value strong magnets.

Advantages of new energy car motor recycling machines

BSGH Granulator specializes in the development and manufacture of various scrap car recycling machines. The new energy vehicle motor recycling machine is BSGH Granulator's new scrap motor recycling solution, which is designed according to the characteristics of new energy vehicle motors. By choosing our new energy car recycling machines, you are investing in solutions that combine efficiency, sustainability, safety, and cost-effectiveness, enhancing your recycling operations and contributing to a greener future.

- High processing Speed

- New Structure and Durability

- Low investment and long-term returns

Our machines are designed to recycle new energy vehicle motors at a high speed, significantly increasing your operational efficiency. They process motors quickly, saving both time and labor costs.

Our machines are made of high-quality materials, durable and can be used for a long time. We have optimized the structure of the machines, and their solid structure ensures that they can provide reliable performance even after long operation, thus reducing the need for frequent maintenance or replacement.

Choosing us means choosing a top-quality machine with zero hidden costs. This not only saves you the cost of machine maintenance and frequent replacement of parts, but also brings you long-term returns. According to the feedback sent by many customers who have cooperated with us, our machines can be used for more than ten years as long as they are properly maintained.

Motor Recycling Machine Feedback

BSGH Granulate’s machines are unique in design and high in quality which are not only very popular in China, but also customers all over the world will buy our machine. After receiving the machines, customers all praise our machines for their high efficiency and strong processing capacity. There is no doubt BSGH is a symbol of quality assurance, so they will cooperate with us more.

Contact Us

Get a free quote on new energy motor recycling machine to change your scrap motors into CASH!!!

Feel free to use this secure form to send an email directly to BSGH Granulator.