Video Description

A testing video for a Malaysian customer, you can refer to it.

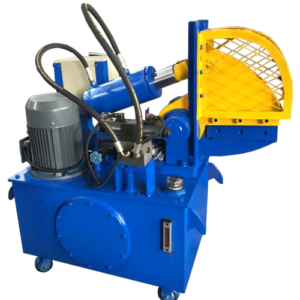

- Machine model: AS-630 Alligator Shear Machine

- Customer from: Malaysia

- Maximum Shear Capability: 630KN

- Maximum Pressure Capability: 120KN

As you can see, our AS-630 alligator shear machine is cutting the steel in the operator’s hand quickly, about 7-8 times per minute. The operation control is convenient and simple, the operator only needs to fix the material on the machine, and the machine cuts very easily, helping you save time and effort.