scrap car recycling machine

recycle all parts in your scrap cars to the greatest extent possibly

- Whole Scrap Car Recycling

- Car Dismantling

- Scrap Car Motor Recycling

- Car Shell Shredding Machine

- Car Looms Wire Recycling

- Car Radiator Recycling

- Car Engines Recycling

- Scrap Car Baler Machine

scrap Car Recycling Machines supplier

BSGH Granulator offers comprehensive solutions to help simplify and enhance your car recycling work. We have scrap car recycling machines (including car shell shredder and car shell baler machine), car engine crushers, magnetic switch recycling machines, car cable recycling machines, car generator recycling machines, and car starter recycling machines etc, no matter which part of the car you want to deal with, you can find the right solution at BSGH Granulator. Our car recycling machines can effectively dismantle and separate the various parts of the car to achieve the purpose of recycling and reuse, helping you to quickly make a profit.

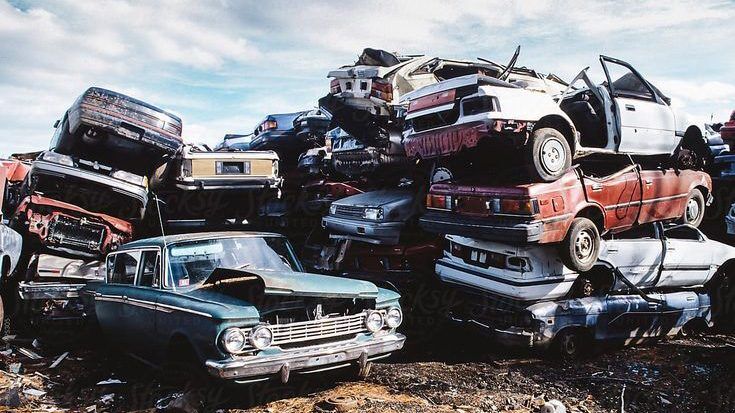

Importance of Recycling Scrap Cars

Practice has proven that more than 90% of the steel and metal parts of scrapped cars can be recycled. What we call car recycling is to process the various parts of scrapped cars under the premise of meeting the standards, and separate the metal resources and non-metallic substances through different treatment methods.

Recycling scrapped cars has important social value and economic benefits. The automobile industry is a typical resource-intensive industry. The production of automobiles requires a large amount of steel, metal, plastic, rubber and other materials. Therefore, if the usable materials on scrapped cars are not recycled, it will not only cause serious waste of resources, but also may pollute the environment.

The recycling of scrapped cars is the key to the green, circular and low-carbon development of the automobile industry. On the one hand, it can ensure the rational circulation of resources, realize the sustainable development of the automobile industry and promote the ecological civilization construction. On the other hand, it can bring good economic benefits to individuals. It can be said that recycling scrapped cars is a business that has the best of both worlds.

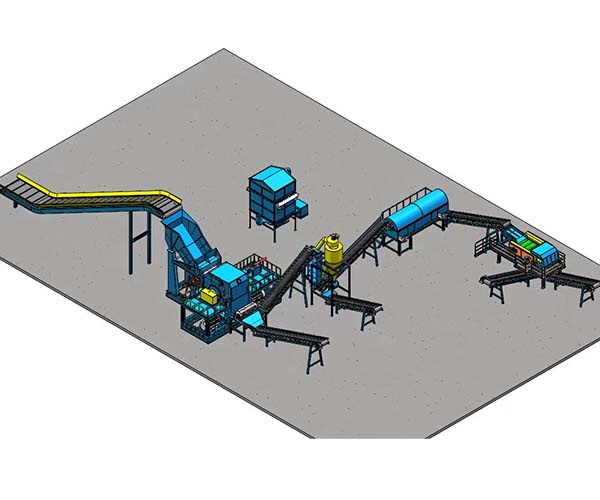

whole scrap car recycling machine for sale

Our whole scrap car recycling machine can recycle the whole scrap car directly, you only need to dismantle the scrap car tyre and car shaft, then all whole scrap cars can be directly feed into machine directly, no need to dismantle the inner parts.

- The car crusher recycling machine is equipped with a shock-absorbing device and does not require anchor bolts.

- The crusher assemble the hydraulic pusher, easy to change the hammer mill head.

- Unique screen replacement design.

- The main shaft is driven by hydraulic motor.

- The dust collection system is a unique reverse suction design and assemble with pulse dust removal.

- Large material discharge function enables the large pieces of material to be discharged from the material chamber without stopping the machine during operation, protecting the crushing chamber and increasing its service life.

- The main shaft of the crusher is equipped with a protective device to increase its service life.

- Car recycling machine is equipped with a forced feeding system. When processing light and thin materials like barrel-type scrap, the hydraulic roller feeder compresses the material, making it easier to enter the crushing chamber and increasing output.

For Different Parts Of The Car, We Have Targeted Professional Solutions

Car Recycling Machines For Sale

Scrap car recycling machine is not one machine but series of machines. Many auto recycling yard boss face the challenge to dealing with moutains of scrap vehicles efficiently. We offer a full range of automotive parts recycling machines that help you quickly dismantle, recover, and process end-of-life cars. With our solutions, you can reduce labor costs, improve productivity, and turn scrap into valuable resources with ease.

Car shell shredder machine

We offer two types of car shell shredder machines: double-shaft shredder and hammer mill car shell shredder machine, which are mainly used to shred car shells into small pieces. If you want to separate the shredded materials, we can also customize the separation system.

Car shell baler machine

If you don’t want to crush the car shell or have baler requests, we also provide car shell baler to solve your car shell storage problem. It can greatly reduce the volume of the car shell, making it convenient for transportation and saving space.

Car engine crusher

For scrap car engines, we have many different types of car engine crushers for you to choose. It can quickly shred the aluminum casing of the engine, which not only facilitates subsequent recycling but also allows you to make more profits.

Auto wire recycling machine

We can help you recycle both copper and plastic from scrap car wires to get double profits. We have more than 100 models of copper wire recycling machines, with processing capacity ranging from 70kg/h to 2000kg/h, each with a copper recovery rate of up to 99.9%.

car motor recycling machine

Scrap car motors have different types: car alternator, car starter, car electromagnetic switch. for different types of car motors will need to use different kinds of motor recycling machine. in BSGH Granulator, you can find all recycling solutions for your scrap motor recycling.

car radiator recycling machine

For scrap car radiator recycling, there are mainly 2 kinds: radiator stripping machine and radiator recycling plant. You can choose the proper model according to your raw material quantities. If you have budget, you can choose higher efficiency recycling plant.

Your trustworthy for car recycling machine supplier

For car recycling, how should you do is more reasonable? Should you process directly or pre-processing? What are the advantages and disadvantages for each? if you not clear, send me an enquiry below.

How does our scrap car recycling machine work?

Below are some operation videos of our scrap vehicle recycling machines, so that you can better understand the operation status, usage methods, and quality of the final products of our machines.

conclusion

Scrapped car recycling has high profits and good development prospects. But at the same time, it is also important to choose high-quality machines to start the scrapped car recycling business. BSGH Granulator is willing to be your reliable partner, use the best machines as your solid backing, and contribute to your scrapped vehicle recycling business.

How can we make your operation leaner and more profitable?

As mentioned before, it is important to choose high-quality machines to start your business. Low-quality scrap car recycling machines may seem cheap on the surface, but choosing low-quality machines often brings you problems such as short service life, low safety, low efficiency, high hidden costs, etc. BSGH Granulator is committed to providing you with the most perfect car recycling solutions. Whether quality, efficiency or service, we strive to satisfy every customer.

Comprehensive Recycling Capability

Whether you need to dismantle, crush, bale, or separate materials from specific components, our scarp car recycling machines can process nearly every recyclable part of a scrap car for you.

Flexible Configurations

Modular designs and customizable configurations let you combine different machines or upgrade capacity as your business grows. From small-scale recycling to industrial-scale scrap yards, you can scale your setup easily.

Superior Material Separation and Purity

Our car recycling system has the most advanced physical separation methods. For example, the car shell shredder separation system can separate crushed aluminum, iron, non-metallic materials, etc., with a separation rate of 99.9%. The cable granulator can maximize the extraction of clean, bright, 100% pure copper from car cables.

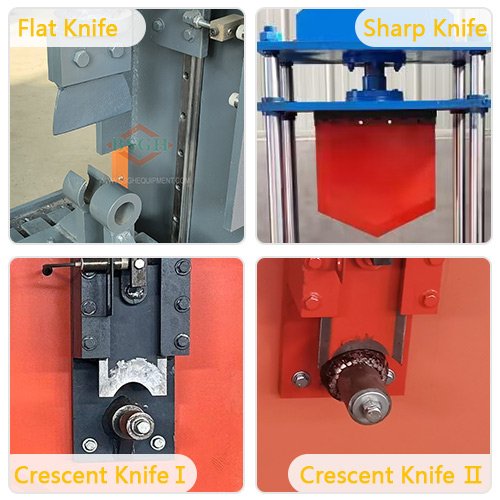

Heavy-Duty Construction and Long Service Life

Core components such as shredder blades are made of high-strength materials such as H13 and SKD-11, ensuring excellent wear resistance and durability. The reinforced frame and solid structure prevent deformation and vibration during high-load processing.

Fully Automated Operation

Intelligent control systems and automated operation significantly reduce manual labor requirements. Most machines can be operated safely by 1–2 workers, lowering operating costs.

Professional Support and Service

We offer one-stop assistance, including model selection, customization, installation guidance, operator training, lifelong technical support, etc. A one-year warranty guarantees long-term reliability and peace of mind.

your professional car recycling machine manufacturer

As a leader in the recycling industry, BSGH Granulator has become the first choice for most people when purchasing scrap car recycling machines. We are never afraid of comparison and competition because we are very confident in our products.

Top quality

At BSGH Granulator, we focus on quality you can trust. All our car recycling machines are built with high-grade, wear-resistant steel and reliable components. This means long-lasting performance, less downtime, and lower maintenance costs for your business.

The most advanced technology

For over 20 years, we have been committed to continuous innovation to keep our machines operating at peak performance. Our advanced technology ensures outstanding efficiency and high recovery rates, helping you achieve reliable results.

Best performance

Over the years, customer feedback has proven that our car recycling machines are powerful, stable, low energy consumption, and cost-effective. As long as you regularly maintain and service the machines, they can bring you long-term and stable benefits.

Competitive prices

We aim to minimize customers' costs and maximize customers' profits. We provide top quality and reasonable prices. By choosing us, you can minimize indirect costs, such as machine maintenance costs, replacement parts costs, etc.

Our Ifat Fair And Canton Fair

FAQ

In scrap cars, there are 8 kinds of raw materials at least, so there are also have 8 kinds of recycling machines, and each kind has its specific machines, prices from usd2900~usd289800.

To be honest, we don't recommend you process the whole car directly, because there are many different materials in scrap cars, and each kind of material has its characteristics, so I recommend you process it separately.

We have car loom wire granulator machine from small to big for you to choose, according to your car wire quantities, we will recommend you the proper model for you, you can consult our sales manager.

Of course. Our standard models can process between 40 kg/h and 2000 kg/h. If you need a higher capacity, we can also design and customize a machine specifically for you.

Yes, we have the whole car recycling machines for you, if you want to feed the whole car into the machine to process directly, it’s also no problem.

If you want smaller fragments, you can choose a shredder. If you need to make materials easier to transport or save space, a baler machine is a good option. We can recommend the right equipment based on your specific requirements.

1. Every five days of use, add lubricating oil to the bearings to ensure the machine operates normally.

2. When the machine is not in use for some time, it should be run for a few minutes to ensure that there is no other debris in the machine.

Firstly, use the cutting machine to cut off the copper winding at one end of the car starter rotor. Secondly, use the hydraulic pressing machine to press the winding, making it easier to take out. Then, heat the scrap car starter using the heating machine to soften the copper winding. Finally, put the car starter on the pulling machine to pull out the copper winding.

Of course, we offer single cutting, single pulling, and cutting and pulling machines for car alternators.

Still confused? See more FAQs or let us know by next contact information!

Tell Us About Your car recycling Machine Needs

There are many types of different scrap materials needed for recycling from your scrap cars, please feel free to tell us your customization need from a car recycling machine. We’ll come up with unique processing solutions that will help you recycle more efficiently and effectively.