Turnkey Copper Wire Recycling Solutions

Our throughout recycling solution puts quality and efficiency at the first place. Our equipment plays an important role in getting good purity of copper whlie maintaining large output.

We offer custom machinery solutions that make project completion go smoothly by using innovative and industry-specific expertise. We focus on top-of-the-line equipment to make sure long-lasting results in the copper recycling field, no matter how big or small your business is.

We can help you find efficient copper recycling methods that will improve both your operation abilities and benefits. You can rest assured that BSGH Granulator machine will work for at least 10 years and help build a long-term business.

About BSGH Granulator

We are your Turnkey Copper Wire Recycling Solutions Provider

We specialize in providing comprehensive turnkey solutions for the recovery of copper wire, offering expertise in designing, installing, and maintaining state-of-the-art recycling machinery tailored to your specific requirements. Our capabilities ensure the efficient processing and recovery of valuable copper from various types of wire, maximizing effectiveness and sustainability of the machine as well.

- Comprehensive Recycling Solutions Provider

- Advanced Recycling Technology Expertise

- Industry-Seasoned Recycling Specialist

- Customized Solutions for Your Requirements

- Efficiency-Driven Recycling Solutions

- Complete Project Management Services

- Sustainable Recycling Excellence

- Client-Centric Approach to Recycling Services

Why Choose Us

How We help out with your Turnkey Copper Wire Recycling

We offer complete solutions for your full copper wire recycling project by using our advanced equipment and years of experience in this field. Our method is designed to make things run more smoothly, and our coordinated and orderly project management services make putting things into action easier. In your recycling pathway, you can count on us to provide long-lasting and customer-focused help.

Comprehensive Turnkey Solutions

We offer full-package solutions for reusing copper wire, which makes the recycling process easier.

Advanced Technology Integration

We use innovative technologies and equipment to make sure that copper recovery works well.

Simplified Project Management

We take care of the whole project, from setting it up to running it, making sure you succeed in getting copper product.

What We Do

BSGH Granulator is the one provides you the best and highest quality machine, giving you the greatest peace of mind. You can find the turkey copper wire recycling solutions here with the best cost performance.

Machinery Solutions

We offer efficient machines for recovering copper wire with different types that make the process run more smoothly with high efficiency.

Our team has rich experience in charge of the whole recycling project with different countries, which demonstrates our strong capabilities,

Our understanding and skills and accumulated experience in practical can help you through the whole process of recycling copper, getting the best results.

get turnkey solutions today.

Get the best prices on turnkey copper wire recycling today. We offer pricing that is customized to your budget, using our industry expertise and efficiency. Contact us right now to receive a price that maximizes your return on investment for a full copper wire recycling service. Don’t pass up this opportunity for getting the greatest pricing.

Why Choose our Turnkey Copper Wire Recycling

Choose our turnkey copper wire recycling options for the best knowledge in the business, advanced technologies, and full support. We guarantee the success of your recycling project by simplifying the process from setup to operation based on our years of experience.

Our focus on efficiency and leading-edge technology helps us get the most copper back, which gives us long-lasting benefits. We put your specific needs first and offer solutions that are tailored to your goals. Our focus on the client means that we give you dedicated help at every step, which makes recycling more efficient and profitable for you.

Choose copper wire recycling options that are both environmentally friendly and cost-effective. These will help your business in real ways.

Partnering with us with your full copper wire recycling needs, we believe this is an informed choice.

How to Get Turnkey Copper Wire Recycling Solutions

Get in touch with our team to get our turnkey copper wire recycling options. We’ll look at your needs, make a plan that fits them perfectly, and help you through the whole implementation process.

01.

Inquiry and Consultation

Getting in touch with our knowledgeable staff is the best way to find out more about our complete copper wire recycling services. We're here to help you and give you advice based on our experience.

02.

Customization and Quotation

Order confirmed, manufacturing initiated; we're committed to delivering your customized recycling solution promptly and efficiently.

03.

Order Confirmation and Manufacturing

Once we get confirmation of your order, we start making your turnkey copper wire recycling options. Our goal is to provide you with reliable and effective recycling options that are suited to your needs.

04.

Delivery and After-Sales Support

Our delivery method has been streamlined to make sure that your turnkey copper wire recycling solution is set up quickly. Our knowledgeable after-sales support team is always ready to answer questions and offer ongoing help as needed.

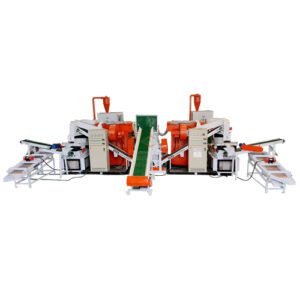

Our copper wire granulator Machines

Turnkey Copper Wire Recycling For your scrap cables

Check out a range of copper wire recycling machines for ideas on how to make things more efficient and more sustainable. Watch innovative machines turn waste wires into useful copper products promoting creativity and environmental responsibility in the recycling industry. Find out about all the good things that can be done with modern recycling equipment, which can lead to a better and more efficient future.

The following products are our several hot sales models, all turnkey solutions for different kinds of cables: car cables, telecommunication cables, armored cables, mixed cables and so on. For these kinds of cables are all common cables our machine regularly processes; for your armored cables, we can customize the solutions for you to recycle and take out the metal contents, here you can find one suitable for your needs.

-

Large Capacity Industrial Copper Cable Granulators for Sale BS-F3000

Read more -

BS-F1000 Copper Wire Granulator with 1T/H Capacity from China

Read more -

Pvc Copper Wire Recycling Machine BS-A1100

Read more -

400~700KG/H Hot Selling BS-N130 Cable Shredder Machine for Sale

Read more -

Dry Copper Wire Granulating Machine BS-D600 for Sale | 400KG/H

Read more -

Best Price BS-D65 Electrostatic Separator Copper Wire Granulator for Sale

Read more -

BS-N125 Copper Recycling Machine with Electrostatic Separator for Scrap Cables

Read more -

Best Cost Performance BS-D60 Copper Wire Separator Machine in Selling

Read more -

BS-D30 Wire Grinding Machine with 300KG/H

Read more -

Fully Automatic BS-D20 Scrap Wire Chopper Machine Factory 200KG/H

Read more -

Buy BS-D75 Small Copper Granulator Machine

Read more -

BS-D55 Wire Shredder With Electrostatic Separator For Sale

Read more -

99.99% Recycling Rate BS-N140 Wire Granulators From BSGHGranulator

Read more -

Best Performance BS-N135 Cable Wire Recycling Machine For Sale

Read more -

Durable BS-D80 Scrap Copper Rice Machine for Sale

Read more -

Affordable BS-D85 Copper Wire Crusher Machine With Electrostatic Separator For Sale

Read more -

BS-AC120 Electric Wire Stripping Machine for Sale

Read more -

BS-AN120 Cable Stripping Machine

Read more -

BS-AC80 Wire Peeling Machine

Read more -

BS-200 Wire Cable Stripping Machine for Sale

Read more

FAQs

Differing machines, like wire strippers, granulators and motor granulators are offred by us. There are more related machines such as: shears, briquettings and compactors which are used before and after the scrap wire process,

Wire stripping machines take off the insulation from copper lines, via cutting and peeling function, leaving only the clean copper core that can be recycled.

A copper wire granulator plays a crucial role in the recycling process by efficiently processing and recycling copper wires. Here’s an overview of its role:

Wire Shredding:

- The granulator begins by shredding or cutting the copper wires into smaller pieces. This step is essential for effective processing.

Separation of Insulation:

- After shredding, the granulator separates the copper from the insulation material. This is typically done through a combination of mechanical processes using airflow separation and vibration.

Size Reduction:

- The separated copper pieces are further reduced in size to facilitate easier handling and transportation.

Copper Recovery:

- The final stage involves recovering the purified copper granules. These granules can then be used in the production of new copper products.

Environmental Benefits:

- Recycling copper through a granulator is an environmentally friendly process as it reduces the need for mining new copper ore. It also minimizes the environmental impact associated with extracting and processing raw materials.

Resource Conservation:

- By recycling copper wires, the granulator contributes to resource conservation, as it allows for the reuse of valuable material that might otherwise be discarded.

Energy Efficiency:

- Recycling copper is often more energy-efficient than extracting copper from its raw ore. Using a granulator in the recycling process helps conserve energy and reduce overall environmental impact.

Yes, sure, our copper wire recycling machine can handle different wire sizes to work with a variety of wire kinds, which makes them useful for a range of recycling tasks.

All of our machines are fully automated, significantly simplifying the recycling process. Their high efficiency minimizes the need for manual intervention, making the entire recycling operation more seamless and user-friendly. With automation at the core, these machines handle various tasks, from the initial shredding of copper wires to the meticulous separation of copper and insulation materials.

Lets Tell Us About Your granulator machine Needs

Tell us what you need from a wire granulator machine. We’ll come up with custom processing solutions that will help you recycle more efficiently and run your business better.

- Whatsapp/Viber: 008613772508206

- Email: coppergranulator@bsghrecycling.com

- Website: https://bsghgranulator.com/