Your Trusted One Stop copper Recycling Solution Provider

Copper Granulator for sale

- BSGH Granulator is a leading copper granulator brand in China since 1995.

- Our copper granulator machine can solve all headache problems in your scrap cable recycling business.

- We also provide you the custom solutions for your wire recycling business to 3T/H.

BSGH Industrial Copper Granulators for sale

BSGH offers more than 100+models of copper granulators and cable granulators, designed to efficiently recycle nearly all types of scrap wire. Whether for industrial or home use, our machines deliver high efficiency and a copper recovery rate of 99.99%. From small-scale operations to large processing facilities, we have solutions that match your capacity requirements. Whatever your needs, there’s a BSGH machine that’s perfect for you.

- Our granulator machine can process from 40KG/H to 3T/H(88ib~6600ib per hour) for scrap cable recycling; can recycling all kinds of scrap cables diameter recommended below 30mm(1.18″) also the heavy cables which recycling rate can reach 99.99%.

- BSGH Granulator price range is from usd4900 to usd159000(this is for standard granulator machine); for custom granulator machine price range is from usd25590 to usd298000(we can custom the largest cable recycling plant);

- Suitable for thick and thin wires: car wires, data cable, telephone cables, solid wire, square wires, romex cables, rubber wire and armored cables etc.

special types of copper granulators

Special heavy-duty copper granulators from BSGH Granulator stand apart from others on the market. This machine has a stronger and more durable structure and support forklift feeding to help save time and effort.

- Special design single shaft shredder for cable crushing;

- Unique square blades differs from others;

- 2 Strong air separator systems.

- Heavy-duty structure enables it to carry more raw materials.

- This extra-large machine has a larger processing quantity of 6000lb/h. If you are a recycling company, scrap yard owner and have about 100T scrap cable per month, it will become your best cable recycling partner.

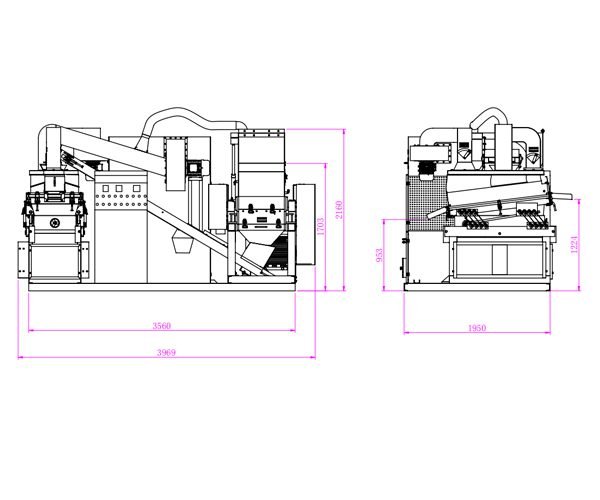

Large industrial copper granulators for sale

Our large copper granulators offer exceptional stability and heavy-duty performance, backed by over 25 years of market proven. Designed with advanced and mature technology, these machines are ideal for industrial applications, capable of handling large-scale cable processing demands. Choose from processing capacities ranging from 1,760 lbs/h to 6,600 lbs/h to meet your specific requirements.

Middle copper granulators for sale

- Procesing range 660Ib-1540Ib/h, one person can easily operate the machine; higher recycling rate; lower power consumption, produce less powder and producing 100% pure copper.

- If your budget is between USD20000-USD40000, also not want too small granulators, you can choose our mid-sized copper granulators.

BS-N125 Copper Granulator

Config: #600 Crusher + Air Separator

Power: 40.5KW

Belong to our N series Wire Granulator

BS-D60 Copper Granulator

Advantages: Lower Noise

Power: 48KW

Best Cost Performance

BS-D65 Copper Granulator

Power: 53KW

Config.: Integrated type

Features: Save Space and Costs

BS-600 Copper Granulator

Power: 63KW

Config: Shredder + Air Separator

Small copper granulators for sale

Best cost performance copper wire granulator machine in the market; cheap price but better quality; processing range 88Ib to 660Ib per hour; Built to last and reliable, these machine are all integrated types, all-in-one.

If your budget is under USD 18,000, you can choose small copper granulators which can help you minimize your costs.

BS-D75 Small Copper Granulator

Config: Smallest 3Phase Copper Granulator Machine

Power: 18KW

BS-D10 Copper Granulator

Power: 24KW

Power Consumption: 16KW/H

BS-D20 Small Copper Granulator

Blades: SKD-11

Power: 28KW

BS-D30 Copper Granulator

Power: 38KW

Power Consumption: 26KW/H

Single-phase copper wire granulators for sale

Built for practicle and get a good result; suitable for home using, hobby, technician and small quantity customers, if you haven’t 3-phase voltage, single phase copper granulator is perfect for you.

BS-S10 Copper Granulator

Feature: Heavy-duty single phase copper granulator

BS-S15 Copper Granulator Machine

Feature: Smallest single phase copper granulator

BS-D75 Copper Granulator Single Phase

This machine can do single phase and 3phase voltage

custom service of copper granulators

Structure

Our copper granulators have an upgraded structure with three core systems: crushing, separation, and dust collection. These part can be made according your situation, Its durable and reasonable structure reduces maintenance and part replacement needs.

Pre-shredder

The double-roller shredder is a heavy-duty pre-crusher for copper granulators, designed to process waste cables into 5-25 cm segments. This reduces impact on the main crusher and protects its blades. With high capacity, strong torque, smooth operation, and low noise, you can get from 3KW shredder to 180KW*2.

Advanced Design

Our crusher adopt an alternating shaft blades system, capable of shredding waste cables into 3-5mm copper-plastic mixed particles. Its robust frame, made from thickened, high-quality steel plates, ensures stable performance, efficient crushing, and low noise, making it ideal for waste cable recycling.

Air Separator

The air separation system is a key component of the copper granulator, designed for efficient copper-plastic separation with a recovery rate of 98% to 99.9%. Its performance relies on precise control of critical parameters, including machine angle, vibration frequency, airflow, discharge speed, and alignment. These factors work together to ensure near 100% copper recovery.

Get a free quote for your copper granulators now!

If you have a demand for a professional copper granulator and are so lucky to meet our machine, please don’t hesitate to send your inquiry to us, and we will provide you with professional solutions details and operation videos for you.

how we promise your

copper granulators

working performance?

Advanced crushing technology of copper granulator ensure minimal copper loss and an efficient power system, achieving excellent crushing results with uniform particle size and high efficiency.

In the separation system, we combine accurate air flow separation and vibration separation technologies: the air flow separator initially separates copper from the mixture based on the weight differences between copper and plastic. Then, a small shaking table utilizes differences in vibration frequency for a second separation. The combination of these two technologies significantly enhances separation precision, ultimately achieving a separation rate of up to 99.99%.

Our high quality copper granulator blades are made from premium alloy steel, such as 96Si and SKD-11, ensuring superior hardness, precision, wear resistance, and heat resistance. Sourced from top steel manufacturers, the blades undergo triple high-temperature forging to enhance strength and durability, followed by precise heat treatment for exceptional performance in demanding conditions.

The small vibrating table is used for the secondary separation of mixed copper and plastic which consists of a frame and a vibrating steel screen mesh. The mesh is a critical component of the vibrating table, playing a vital role in both separation effectiveness and efficiency. Our vibrating screen mesh is made from 304 stainless steel, providing high strength and excellent impact resistance. This allows for precise separation of copper and plastic while ensuring exceptional durability for long-term, stable operation. We have designed a variety of mesh sizes to meet a wide range of separation needs.

The air separator sieve of coppe granulators features a four-layer design constructed from galvanized steel, a wooden frame, and two layers of high-quality 304 stainless steel. This mesh is essential in the airflow separation process of copper granulators, as it evenly distributes the airflow across the base of the sieve, ensuring uniform force on the materials for effective separation. Our airflow separation mesh is available in 160 mesh and 200 mesh sizes, allowing for the separation of various materials by simply changing the mesh size.

Production process and quality control

STEP 1- RAW MATERIAL

First of all, premium raw materials are the most important factor to ensure the high quality of our copper granulators machine. We choose thickened high-quality steel plates to make the machine body and high-hardness and high-wear-resistant steel to make the blades, ensuring excellent performance and high durability. After preparing the raw materials, we will cut and drill them.

STEP 2- HEAT TREATMENT

Heat treatment plays a vital role in the manufacturing process of copper granulators. Good heat treatment can improve the hardness and strength of the blades so that they will not become dull quickly, and also enhance the toughness of the steel frame and other load-bearing parts so that they will not be damaged frequently.

STEP 3- LATHE PROCESSING

This step mainly involves processing the main shaft, air separator system shaft, and other parts. Workers need to accurately grasp every detail of these main parts, as even a slight deviation will affect the overall performance of the copper granulator.

STEP 4- SPARE PARTS WELDING

The processed parts are welded into the main crusher, air separator, and other equipment. Strong welding provides the machine with high stability, durability, and safety.

STEP 5- FINISHED PRODUCTS WITHOUT PAINTING

This step is mainly to weld the various components closely together to form a complete machine.

STEP 6- COMPREHENSIVE TESTING

We will conduct multiple tests and trial runs on the machine to ensure that every component can achieve optimal working performance.

STEP 7- WHOLE MACHINE FINISHED

This is the last step of the machine production. We will polish and paint the machine, and assemble and debug it into a brand-new machine. We support free customization of your favorite color and your company’s logo.

Why US

Machine Diversity

We offer over 60 models of copper wire granulators, with processing capacities ranging from 40 KG/H to 3000 KG/H, capable of meeting the recycling needs of nearly all scales of waste cable recovery. Whether for individual recyclers, small recycling stations, or large metal recycling processing plants, customers can find equipment that best suits their specific requirements. Our goal is to provide flexible and efficient solutions, ensuring that clients achieve optimal recovery results under various operating conditions.

Versatility in Cable Processing

Our new copper wire granulator have a wide range of applications, capable of processing both copper and aluminum wires, as well as certain specialized materials. They can accurately separate copper from high-copper-content cables such as square wires, communication wires, and automotive wires. Additionally, our equipment is capable of recovering up to 99.99% of copper from various types of mixed wires and fine strands. By incorporating auxiliary equipment, we can also efficiently recover copper from iron-containing cables and fine wires, further enhancing recovery efficiency and separation rates.

Structural Versatility

We offer flexible scrap copper granulator machine configurations that can be tailored to the types of raw materials and processing volumes required by our customers. Based on standard models, additional auxiliary equipment such as pre-crushers, conveyors, storage hoppers, electrostatic separators, and magnetic separators can be seamlessly integrated. This versatile configuration ensures that the equipment effectively meets our customers' specific requirements.

Easy to Operate

Our wire granulator machines are designed with user-friendliness in mind, featuring a simple design that makes operation straightforward. The entire recycling process can be managed by a single operator who is responsible for feeding materials and collecting the final products. Additionally, our machines are equipped with an electrical control cabinet that allows operators to easily adjust airflow and vibration frequency. Operators can also monitor voltage and current levels in real-time through the control cabinet, enhancing operational precision and ensuring that the machine consistently maintains optimal performance in response to varying processing requirements.

comprehensive service from presale to aftersale

BSGH Granulator strives to satisfy more customers by continuously optimizing services. We provide one-stop service from pre-sales, during sales, to after-sales to ensure that your rights are effectively protected. Our commitment to excellence ensures that you receive the best service and assistance, and helps your business flourish through our advanced recycling solutions.

1. Pre-sale services

When you choose a good cable copper granulator machine from us, our sales manager will accurately recommend the right model for you based on your waste cable types, quantity and budget.

- Customization options: If you have special needs, please inform our sales manager in time. We have a wealth of customization options to meet your requirements.

- Perfect design: We support factory design, circuit design and machine placement design.

2. In-sale services

- After receiving the 30% deposit, we will immediately prepare the production for you. We will continue to follow up on the production process and update you on the production situation in time.

- We will strictly control the quality of the machines during the production process and conduct comprehensive tests on the machines before shipment.

- Once production finishes, we will arrange shipment for you as soon as possible and continue to monitor the shipment status of the machine until you receive it safely.

3. After-sale services

All our scrap copper granulators machine come with a one-year warranty, most import is machine itself haven’t any problem we can promise you 100%. Therefore, you can feel confident to buy our machines, and we will provide you with sufficient and safe after-sales protection.

- Quick response: We also support lifelong 24-hour online service to solve all your machine problems online.

copper granulator production site

our ifat fair and canton fair

2 times offline exhibitions IFAT fair and 2 times offline exhibitions Canton fair

FAQ

We have 5 types of copper granulator machine besides from small to big total have 60+ models.

Copper granulator from BSGH Granulator price is varies: small granulator from usd4900 to usd14900; middle size granulator price from usd19000 to usd59900; big granulator price from usd59000 to usd209000, for the custom recycling line price will be higher, consult our staff to get more details.

For our standard copper wire granulators, the smallest capacity is about 40KG/H, the biggest is about 3T/H, if you have bigger demands, don't worry, we provide custom service for you.

The copper granulator is mainly used to separate waste cables' metal core and insulation layer and recover valuable metals, usually copper or aluminum. It works by crushing first and then separating, with super high efficiency and separation rate, and is the first choice for various recyclers.

Absolutely, our customer can get the machine cost back within half month to one month.

1-year warranty for the copper granulator machine's main body, not including the wearing parts.

For big granulators, we mainly doing EXW, FOB, CIF,CFR; for small granulators except for previous terms maybe DDU is also used.

Normally for small and medium also standard granuators, we can produce for you about 20-30days, if big machine, then according to your voltage and confirm normally about 30-40days.