In 2024, the copper scrap machine market is about to go through huge changes because of new technologies, changes in global supply lines, and a growing demand for recycled copper. This makes copper scrap equipment more important than ever. Copper recycling is becoming a profitable industry because new technologies for handling and sorting waste copper make it more efficient and increase the output.

Understanding the Current State of the Copper Scrap Machine Market

Market Trends Leading into 2024

- As a common used metal, copper is widely used in people’s production and life. It is extensively used in the electronics industry to make cables and wires due to its good electrical conductivity. Because of its good thermal conductivity, it is often used as raw material for radiators of various products. In addition, copper can be seen in pipes and related accessories in the construction industry and many decorations in life. All in all, the usage of copper is indispensable.

2. Significant decline in global copper resource raises concerns about copper supply shortages. In the past, when the copper market was in short supply, scrap copper was usually able to make up for the shortfall. However, according to data, scrap copper recycling accounts for 20% of global refined copper production and nearly 30% of semi-finished copper consumption. Therefore, Goldman Sachs judges that the shortage next year will far exceed the capacity of the scrap copper recycling system to provide additional supply.

3. Adoption of Stringent Environmental Standards: To cut down on carbon emissions and protect natural resources, countries around the world are enacting tighter environmental laws and setting high recycling goals.

4. Integration of Digital Technologies: Digital technologies like IOT (Internet of Things), AI (Artificial Intelligence), and machine learning are being used more and more in the copper scrap machine market to improve operations, sorting accuracy, and the general efficiency of processing.

5. Shift Towards Circular Economy Models: Circle economy models stress the need to recycle and reuse things, and more and more businesses are going towards them.

Methodology for Forecasting

This forecast leverages a combination of primary and secondary research, including industry reports, government publications, and interviews with market leaders. The analysis also incorporates historical data trends to project future market movements.

Factors Impacting the 2024 Copper Scrap Machine Market Supply and Demand Dynamics

There are many economic, environmental and technological factors that affect the copper scrap machine market. The prediction for 2024 is largely based on how supply and demand change.

1. Recycling technology advances

New copper sorting, shredding, and granulating technologies are boosting recycling and raising copper quality to meet market demand.

2. Sustainable Goals and Environmental Regulations

Demand for recycled copper is rising due to stricter environmental restrictions and worldwide sustainability efforts. This encourages copper scrap machine manufacturers to develop greener recycling processes.

3. Raw copper price volatility.

Raw copper prices affect recycling’s profitability. As the expenses of raw copper grow, more people choose to get copper through copper scrap machines cause the quality and purity of recycled copper can meet the standard of use requirement with cheaper price.

4. Recycling Infrastructure Growth.

Considering the urgency of copper demand among countries, specially developing nations, the demand of copper scrap machine is huge in order to develop their economic and protect the environment at the same time so expanding the scale of recycling infrastructure with quick action plays an important role in their plan.

Regional Analysis of Copper Scrap Machine Market

As a result of the fast development and growing concern for the environment in Asia, the market for copper scrap machines is growing very quickly. This growth is being led by countries like China and USA, which have a lot of copper scrap from industries like building and electronics that are growing quickly. There are also a lot of investments in these countries to make recycling better. This is because the governments support and encourage Industry sustainable development strategy practices in an effort to less the damage they do to the environment.

Europe is known for having strict rules about the environment and big goals for recycling, which is driving the need for more modern technologies to process copper scrap. Because the European Union wants to promote a circular economy, its member states are investing in cutting-edge recycling facilities. This has made the EU a major market for copper scrap machinery. Some of the first countries who using new technologies to make recycling more efficient and meet government rules are Germany, France, and the UK.

There is a steady need for copper scrap tools in North America, especially in the United States, where recycling is a big business. The focus on sustainable material management and the drive to improve recycling in the United States itself to reducing reliance on materials brought from other countries are both helping the market grow. It is believed that the region’s focus on new ideas and efficient recycling methods will keep its market growth going strong.

Machine Types and Innovations

Copper junk recycle machine innovations are very important for the recycling industry because they can meet the growing need for processing copper scrap in a way that is efficient, environmentally friendly, and cost-effective. Better technologies for organizing, automation, and higher efficiency across all machine types are moving the market forward, which is good for both the economy and the environment. For copper scrap machinery, there’s different types, just like copper scrap from cables, radiators, motors and so on.

Sorting Systems

Many improvements have been made to sorting systems, which now use more advanced technologies to better separate copper from mixed scrap. Modern sorting systems use a mix of sensors and technologies for sorting, such as electromagnetic sensors, eddy current separators, and high-tech vision systems. These technologies make it possible to precisely find and separate copper, even from streams that are very mixed or contaminated. This makes the reclaimed copper much more pure. Using artificial intelligence (AI) and machine learning algorithms together makes the sorting process even better. It makes it possible for smart and flexible sorting methods that can improve the efficiency of separation in real time.

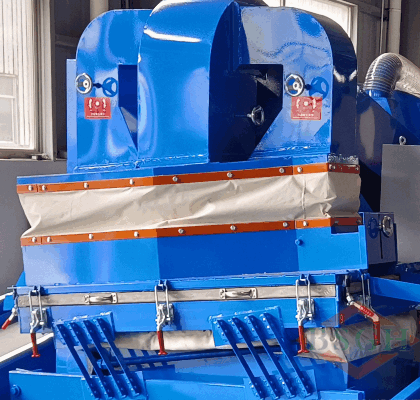

Shredders

Shredders are very important for the first steps in handling copper scrap material because they break it up into pieces that can be handled for further processing. Recent improvements to shredder technology have made the shredder safer, less energy use and lower operating costs. Modern shredders are designed to cut through a wide range of copper scrap quickly and efficiently, from big chunks to small wires. Applying sturdy material and good performance of wear resistance has made shredders last longer and require less upkeep. Our machine not only has the above advantages but also spends time on technological innovations in the structure of the shredder. The structure of the shredder have many different types, the most we see in the market is dual-shaft shredders. During the process, the two shafts rotate toward each other then cause part of the copper and aluminum to be screwed together. We have upgraded the technology to solve the problem based on the guarantee of efficiency.

The granulators

Granulators make the treated copper scrap even better by breaking it up into smaller, more uniform pieces. This makes it easier to sort and clean. Improvements in the design of granulators have made equipment that are not only more productive but also able to make better granulated copper. Some of these changes include more accurate cutting machines and a system that uses less energy to keep dust and noise from bothering people. In addition, some granulators now have sorting and cleaning systems built right in. This makes recycling easier and more efficient overall. Granulators is mainly for crushing raw materials.

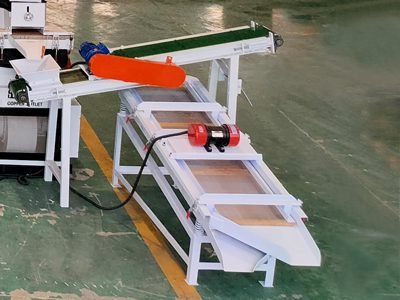

Separator

Our BSGH separation system mainly consists of an air separator and vibrating table. Air separator generates wind comes from the bottom. The strong wind force cooperates with the vibration to separate. Then the products will be further separated on the vibrating table. The table tilt angle and frequency of vibrating are also carefully studied by us to achieve the best separation effect.

Electrostatic separator

The electrostatic separator performs more detailed separation function based on the difference in charge of the materials. As China’s leading electrostatic separator supplier, our machine can perfectly separate different materials in various fields like plastic, metal and electronic waste. We have D series and N series electrostatic separators, both of which can be assembled with other machines. They all adopt high-quality and advanced production technology to ensure its stability. It also has excellent performance and can work stably and efficiently for a long time. Low noise, high output, dust-free and environmentally friendly are concentrated in one machine. Among them, D series machines are more affordable and can help you save costs.

Baler and Shears

Shears and balers are used for cutting, packing and baling the recycled copper which makes it easier to move and sell. The newest models have better automation and control systems that make them run more reliably and efficiently. As the market changes, more improvements will likely be created in technology field used to handle copper scrap. This will help the recycling industry grow stably and last longer.

2024 Copper Scrap Machine Market Forecast

| Machine Type | 2023 Sales (Units) | 2024 Forecasted Sales (Units) | Year-over-Year Growth |

| Sorting Systems | 1200 | 1440 | 20% |

| Shredders | 850 | 1020 | 20% |

| Granulators | 900 | 1080 | 20% |

| Baler and Shears | 750 | 900 | 20% |

Navigating the Future: Challenges and Opportunities in the Copper Scrap Machine Industry

Copper scrap machine market nears tipping point. Increasing demand for recovered copper will drive growth until 2024. However, its expansion has challenges and hazards. Companies preparing to meet growing demand may face many issues, preventing them from capitalizing on market prospects. To manage the industry’s future, stakeholders must recognize current issues and long-term prospects.

Copper Scrap Machine Manufacturer Challenges and Risks

1. technological advancements: R&D must be heavily funded to keep up with rapid technology change. Manufacturers must always innovate to meet recycling industry needs and make their goods more efficient and cost-effective.

2. Raw material pricing fluctuations: Global issues, market demand, and supply concerns affect copper prices. This can affect copper scrap tool production and price.

3. Supply Chain Disruptions: Pandemics, trade conflicts, and organizational issues will disrupt the supply chain, making machine parts and supplies hard to get.

4. Compliance with regulations: As environmental laws become more stringent, businesses must invest in cleaner, longer-lasting production methods. Ensuring these regulations followed, manufacturers need to invest more energy and money in breaking through technical bottlenecks to overcome these new challenges.

5. Market competition: As new companies enter the market with new ideas, the competition intensifies. To be competitive, producers must not only come up with innovative ideas, but also sell their products effectively and develop strong customer relationships.

6. Living up to expected demand: Because more and more people wants to get the recovered copper, companies have to expand the production scale to keep up with the quick demand speed made by the market. Scaling up doesn’t just mean making more machines; it also means making sure they are of good quality and meet the changing needs of the business.

Chances and the Future for Machine Making Companies

Even with these problems, the future looks good for scrap copper recycling machine producing companies, there are several chances for them to grow:

1. Trends in sustainability: The push for sustainability demand and cycle economy models around the world is a huge chance for producers. More and more people want machinery that can process copper trash more quickly also with less damage to the environment.

2. Technology Integration: AI, IoT, and machine learning are some of the latest technological advances that companies can use to improve their products, run their businesses more efficiently, and give their customers more services that are good for them.

3. The world market is growing. Emerging countries, especially Asia and Africa, South America, develop their information technology quickly and implement more open foreign policy which open new ways for makers to expand their market.

4. Customization and Service Providers: In a competitive market, producers can set themselves apart by offering unique solutions and full after-sales services.

Conclusion

The 2024 Copper Scrap Machine Market Forecast shows the industry is about to grow a lot, thanks to more people wanting to recover copper. Manufacturers face problems like coming up with new technologies and following rules, but there are also a lot of chances for growth and development as well. Copper scrap machine makers can set themselves up for long-term success in an industry through changing quickly by facing these problems head-on and taking advantage of the new possibilities. The copper trash machine market will be very important in shaping the future of metal recycling as the world moves towards more eco-friendly and effective ways to recycle.

Our advanced copper scrap machines improve recycling and the environment. Upgrade your processes now as recycled copper demand rises. Our top-notch equipment maximizes productivity and earnings while minimizes waste. Take advantage of this chance and pioneer the sustainable recycling. Learn about our machines and let us help you develop your business, Get started now.