How to correctly operate a Copper Granulator Machine?

When buyers purchase a machine, before using they need time to get familiar with it for a complete understanding, which will decrease the machine failure rate and save a lot of time in the future. What’s more, reasonable maintenance methods are also important, the right and appropriate maintenance can extend its service life effectively and make sure it can process waste wires at a high speed and get high-quality copper products successfully. We write this article for you to help you grasp all the relevant information better and faster.

Troubleshoot—— 25 Tips to Make You Succeed in Copper Wire Granulator Business

If granulator machines can’t operate at their optimal performance or have some malfunctions, the reasons may be complex due to the unique structures of different machine parts. But we are capable of dealing with these troubles with our rich industry experience.

Now, we list 25 tips from 6 aspects to help you understand granulator machines in the market and provide solutions to all the problems that customers may encounter from installation to use.

25 Tips to Make Copper Wire Granulator Reach Best

Improper operation

1. Feeding too many waste wires will cause the main shredder to get stuck. If you meet this problem, you can shut it down immediately and cut off the main power supply, then open the upper cover, and remove the jammed waste wires.

2. If waste wires are covered with water, or oil, or wrapped with electrical tape, they cannot be separated directly. In these cases, you can wipe them, clean the oil on their surface and remove the wrapped electrical tape, but for different kinds of cables need to be different methods to process:

- For oil cables, you can use our water granulator machine to process them and add the solvent into the water.

- For car cables and cable with tapes, you can add some talcum powder when you process or before recycling.

3. Screws are mostly used in granulator machines production and play an important role in connection, so every screw must be tightened greatly. If you run the machine without tightening the screws enough, it will be easily damaged to the machine itself.

4. Check the support plates on both sides of the air separator system regularly and replace them promptly if there are any cracks or breaks.

5. The machine needs about 20 minutes of break to be ensured after every 4 hours of work, or else it will be harmful to the machine.

6. Check whether the direction of spindle rotation is consistent with the direction shown on the protective cover. If it is wrong, you should make a change.

7. Try not to tie the dust bag mouth tightly and leave a bowl-sized space for exhaust.

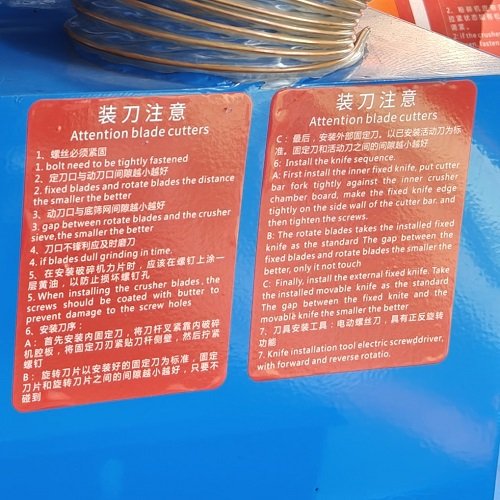

Abnormalities in the copper outlet and plastic outlet

8. If no copper particles come out of the copper outlet, speed up the vibrating table and reduce wind force.

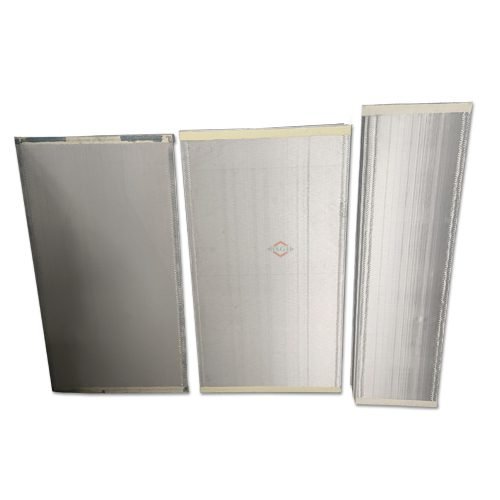

9. If plastic particles come out of the copper outlet, slow down the vibrating table and increase wind force.

10. If no plastic particles come out of the plastic outlet, slow down the vibrating table and increase the wind force.

11. If copper particles come out of the plastic outlet, speed up the vibrating table and reduce the wind force.

12. The copper outlet of the air separator is equipped with a press plate, which is adjustable in height. The lower the pressing plate is, the harder it is for the copper product to come out. Generally, the pressing plate is about 3cm away over the air separator sieve surface.

Bad separation effect

The reasons for the poor separation effect can be analyzed depending mainly on three aspects: the situation of waste wires, blades, and crusher sieve or the operation.

13. If the interior of the waste wire contains hemp rope, fiber, aluminum, platinum and other substances, which will affect the separation effect.

14. If the blades are severely worn or not sharp enough, some of the waste wires cannot be completely cut off but are pulled off. The length of them is relatively long which is not conducive to subsequent separation therefore affects the final product, so you need to sharpening blades.

Shredder blades as follows:

15. If the raw material stuck in the crusher, then you need to change to a bigger crusher sieve.

16. Improper installation of the blade will slow down the speed of cutting as well as affect the separation result.

17. The machine should be kept in level ground which means there can’t be any shaking during operation. The machine shaking will disturb the vibration generated by the air separator system and vibrating table which is the main basis for separating copper from plastic skins. If the shaking is caused by a gap between the machine chassis and the ground, you can insert iron pieces into until the whole machine can work stable.

????The clean methods of the machine

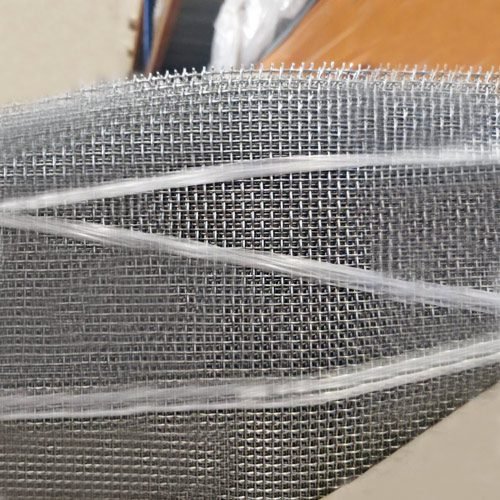

18. The air inlet filter and separation sieve must be cleaned in time. Use an air gun to clean the debris inside air separator sieves regularly to ensure the normal separation of the machine separation system, blockage of the machine will affect the separation effect. When cleaning, you need to remove them first and then put the high-pressure air gun against the screen surface to blow away the blocked dust from the front to the back. If there are fine wires stuck in the mesh screen, you can use a scraper to remove them.

19. Dust collection bags also need to be cleaned in time to prevent the bags from clogging and affecting exhaust. You can open the dust collection box first and then hit it with a stick with appropriate force. If the force is too small, it will have no cleaning effect. If the force is too strong, it may damage the bag.

⚙️Machine Maintenance

20. The main bearings of the crusher, separator, and electrostatic separator should be filled with high-pressure and high-temperature resistant butter every 3 months.

21. The main bearing of the separator and the eccentric wheel on both sides should be filled with high-pressure and high-temperature butter every 4 months.

22. The front and back sides of the insulation board of the electric wire rack should be cleaned with an air gun one time every 10 days and the discharge wire should be wiped with a cloth once a month.

⚠️Safe operation

23. When feeding, be careful not to let the waste wires wrap around any part of the human body.

24. Spiral blades rotate at high speed inside the winch cage mouth, so do not put any part of your body into it.

25. There is high-voltage electricity in the electrostatic compartment. Do not put anything into it to avoid hurting.

Your Best Choice – BSGH Granulator

When you operate the machine, you can ask our sales staff, we have experience in this field for more than 25years, you can take more videos for us and show us even if you use the machine best, we also can check whether can adjust for you to the better effect, bigger processing capacity.

When you use BSGH Granulators, you will have less troubles and have a better experience and pleasant journey for making more money.

Conclusion

This article acts as a communication link and bridge between products and customers. We hope it can help customers better understand product functions, performance, and other related information. Secondly, this article enables customers to use and operate the product correctly and avoid problems and losses caused by misunderstanding or incorrect operation. If you want to know more information, you can contact our staff at any time.