Electrostatic Separator Manufacturer

BSGH Granulator/3T/CopperTai is a reliable electrostatic separator manufacturer, which significantly affects improving and innovation of electrostatic separators. We only provide high-performance machines and professional one-stop service.

Your Electrostatic Separator Machine Manufacturer in China

We are a leading manufacturer of electrostatic separators machine in China, have advanced technology and equipment to produce high-quality products and have a strong R&D team to develop new products and solutions.

Electrostatic separator machines are versatile and can be used in many different applications where the separation of materials is required. Here we mainly talk about applications in cable recycling field: BSGH electrostatic separators are commonly used in the recycling of various materials like plastic, metal, and electronic waste. Machines can separate different materials based on their electrical conductivity or charge, we mainly have D series and N series electrostatic separation machines to assemble with different machines.

In order to configure our high-end cable granulator and get a high recycling rate, BSGH Granulator also put ourselves into studying electrostatic separators and now we have advanced technology and equipment to produce high-quality products and have a strong R&D team to develop new products and solutions.

We all know electrostatic separators are versatile and can be used in many different applications, BSGH as a leading electrostatic separator supplier in China now, our electrostatic separator can perfectly separate different materials in various fields.

Here we mainly talk about applications in cable recycling field: It is commonly used in the recycling of various materials like plastic, metal, and electronic waste. Machines can separate different materials based on their electrical conductivity or charge, we mainly have D series and N series electrostatic separation machines to assemble with different machines.

N Series High-End Electrostatic separation Equipment

N series machine is the advanced machine in BSGH Granulator, in order to assemble with cable recycling machine, we invent 2 types for cooperating with N series large capacity granulators and medium capacity granulators machines, one is small other is bigger one.

Advantages of BSGH N series electrostatic separator machines

1. Adopt high-quality and advanced production processes, which can ensure the stability of the machine.

2. Machine performance is so excellent that can work stably and efficiently for a long time.

3. High quality with strict quality control and continuous innovation.

4. Low noise, high output , dust free and environmentally friendly.

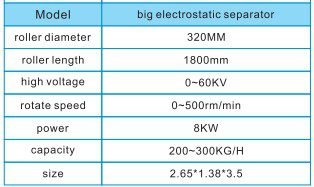

Big Electrostatic separation

- Technical Data

- Machine Details

- Related Cable Granulator

- Technical Data

- Related Cable Granulator

Small Electrostatic Separation

D Series High Cost-Performance Electrostatic Separator Machine

D series is the symbol of the affordable machine in BSGH Granulator. In order to cooperate well with different models of D series cable granulators, we mainly released 3 types of electrostatic separator machines. Also, you can choose the model according to your demands.

Advantages of D series machines

- The D series machines are designed to use high-quality materials, which ensures that they are durable and can be used for a long time.

2. We have a wealth of experience in producing electrostatic separators, and we are committed to continuously improving our equipment based on customer feedback. This ensures that the machine can be effectively optimized for customer needs.

3. High cost-performance. D series machines are affordable, which can save costs of investment.

| Size | L1830xW1250xH2500MM | Weight | 800kg |

|---|---|---|---|

| Power | 2.2KW | Voltage | 380V/Customization |

| Size | L1830xW1250xH2500MM | Weight | 800kg |

|---|---|---|---|

| Power | 2.2KW | Voltage | 380V/Customization |

| Size | L2600xW1250xH2500MM | Weight | 1200kg |

|---|---|---|---|

| Power | 2.2KW | Voltage | 380V/Customization |

High separation rate electrostatic separator company BSGH Granulator

What is electrostatic separator?

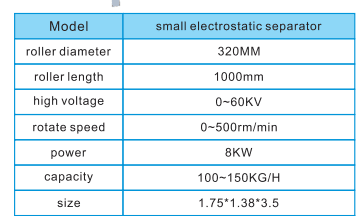

An electrostatic separator machine is a device that uses the principle of electrostatic force to separate materials based on their electrical properties.

BSGHGranulator Electrostatic Separation machine is a support equipment to recycle copper from plastic. Due to the cable granulator recycling copper with the principle of gravity and wind, some thin and light copper is hard to be recycled, this condition can be solved by an electrostatic separator. It is equipped after the plastic outlet vibrating table and recycles thin copper granules from plastic granules by their different electrostatic properties, which can reduce copper loss.

Electrostatic Separator Working Principle

Electrostatic Separation equipment separates copper and plastic based on different electrostatic properties of copper and plastic. By subjecting copper-plastic granules to an electric field, the copper can be attracted to a positively charged electrode and the plastic is repelled and can be collected separately.

What are the other applications of electrostatic separator?

Electrostatic separator machines can be used to separate a wide variety of materials, including conductive and non-conductive materials, as well as materials with different levels of conductivity. They are often used to recover valuable metals from electronic waste or separate plastics from other types of waste for recycling purposes.

metal and non-metal

Mineral sorting

Grinding wheel ash extract metal

reasons you need an electrostatic separation Equipment

- More Profit

- Enviroment friendly

- Easy to operate

Electrostatic separation machines can improve the recycling rate and recycling value.

It uses a physical method to separate copper and plastic, pollution won’t be produced in the whole process. And the purpose of separating is reycling the material, which is definitely good for our enviroment.

Adopt PLC automaticly control, you don’t need to learn many knowledges when you use this machine and it is very easy to operate.

Why choose BSGHgranulator electrostatic separation equipment?

Higher Separating rate

Double recycle copper scrap to reduce copper loss. Here you can get the pure plastic, copper with less plastic you can put into machine recycling again.

less maintainance

Our machine no need frequently maintainance, BSGH equipment is known as superior quality, which can work perfectly for a long time and save you using costs.

low energy consumption

We usually use 3 phase power to run the machine, which is expensive in many countries, so we minimized energy waste, you can save more money when you using machine.

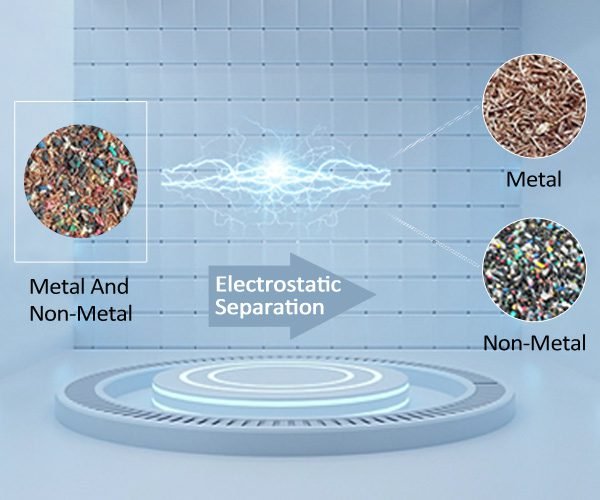

How to maximize the effectiveness of electrostatic separators?

Refers to the voltage between the charged electrode and the ground electrode (drum). Different materials require different sorting voltages. If voltage is too high, it will affect the material recovery rate, and if voltage is too low, it is not conducive to recovery purity.

If the distance between the charged electrode and the grounding electrode is too small, spark discharge will easily occur, which will seriously affect the beneficiation effect; if the distance is too big, the electric field is relatively stable and it is difficult to achieve effective separation. At present, the most commonly used in the production process is between 60~80mm.

Drum speed directly affects the residence time of selected materials in the electric field area. The adjustment of the rotating speed is related to the particle size of the material. If the particle size is large, the rotating speed is required to be slow; if the particle size is small, the rotating speed is required to be fast.

When the raw material contains moisture, it will increase the conductivity of the non-conductor and affect the separation effect. Removing the moisture on material surface and restoring the inherent electrical properties of different minerals can make the sorting results more accurate.

how does electrostatic separation reduce pollution?

After being processed by electrostatic separator, the number of hazardous materials that are sent to landfills or incinerators can be reduced, which can reduce pollution.

Electrostatic separation machine recycle raw materials with physical method, which can avoid secondary pollution

The whole recycling process happens in a hermetic space and it won't exhaust waste water or air

How to operate a Electrostatic Separator correctly?

Correctly connect all wires well

If frenquently spark,then adjust it far away little from the static roller.

For fuse need to be tight.

Baffle and static roller distance about 5cm.

lf copper outlet have much plastic, adjust the baffle and static roller far a little.

lf the static roller can’t absorb the material, then adjust this slower.

lf plastic is clean, this can adjust quicker.

lf plastic not clean, this need adjust slower.Drilling a hole under ground at least 1M to reach up the earth, take a angle iron,do as above picture, connect one wire to the angele iron.

put the angle iron into the hole.

Drilling a hole under ground at least 1M to reach up the earth

Take a angle iron, connect one wire to the angele iron.

Put the angle iron into the hole.

Keep the hole moist, also can input some salty water,then electric conductivity is better.

Loading picture of electrostatic separator

It's Our Great Honor To Serve You.

Send us a message if you have any questions or requests. Our experts will give you a reply within 1 hours and help you select the proper capacity machine you want.

008613772508206

coppergranulator@bsghrecycling.com

*All your information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe with us.

Ask A free quote

REPLY WITHIN 24HOURS.

Start growing with BSGH now, we can help you wholesale or use the machine at best effect.