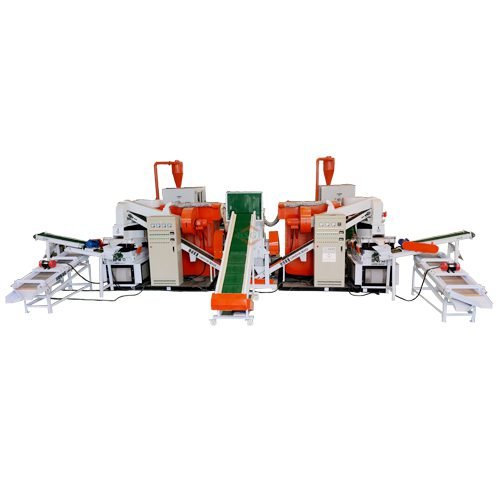

Copper Recovery System

The Copper Recovery System is a precision-engineered machine designed to maximize copper recovery from waste cable materials. It employs vibration and advanced separation methods to accurately separate copper, ensuring high purity and yield, the system is designed for high-capacity processing and can efficiently handle a variety of material kinds. Durability is critical, with the system designed to work consistently over lengthy periods, its user-centric design simplifies operation and maintenance, making it dependable for effectively enhancing copper recovery rates. This system is a strategic investment in the improvement of copper recycling operations and operational profitability.

About BSGH Granulator

We are your Wire Recycling System Provider

We are your Wire Recycling System Provider, supplying modern recycling technology, efficient wire recovery systems, outstanding support, and dependable machines to improve operational efficiency.

- Utilizing the latest in recycling innovations for maximum efficiency and wire recovery.

- Offering systems designed to fit specific operational needs and capacities.

- Providing durable and dependable equipment for long-term use.

- Backed by years of industry experience and technical know-how.

- Ensuring customer satisfaction through installation, training, and ongoing support.

- Focused on offering solutions that contribute to sustainable recycling processes.

Why Choose Us

How we help out with your Copper Recovery System

We provide advanced sturdy Copper Recovery Systems with specific separation, high-yielding, advanced technology, and extended technical assistance for optimal recycling efficiency.

Advanced Technology Application

We apply sophisticated technology in our Copper Recovery Systems for enhanced separation and purity, ensuring efficient processing and high-quality output with 99.9% recycling rate.

System Configuration to Specifications

Every machine in our copper recycling system is configured with every parts it needs. Moreover, considering the aging and damage of machine accessories, We also give away some machine accessories as backup. If some parts of the machine fail or need to exchange , there are backup solutions to solve the problem.

Continual Support and Technical Assistance

Providing ongoing technical support and maintenance services, we help keep your system in optimal condition, ensuring consistent performance and long longevity.

Our copper wire granulator Machines

The Copper Recovery System simplify your recycling

Maximize recycling rates

We constantly update our machine performance over the years trying to provide

the best service for you and contributing to enhance the throughput of the end

product.

Copper recovery system of granulator

Copper recovery system of stripper

Copper recovery system of radiator

Copper recovery system of electric motors

What We Do

Maximize recycling rates

We constantly update our machine performance over the years trying to provide the best service for you and contributing to enhancing the throughput of the end product.

Offering detailed maintenance and support, we ensure your system operates at its best, reducing downtime and enhancing productivity.

Staying abreast of industry developments, we integrate the latest techniques and improvements into your system for sustained and superior performance.

get Best price today.

Get an incredible offer on our Copper Recovery System today. Elevate your recycling process with our dependable technology, which is meant to increase copper yield and operational efficiency. Invest in our machines and you will get a high-quality and wonderful performance machine at a preferential price. It will become a wise choice for your investment. Improve your operating capacity with our tried-and-true system, and reap the rewards of higher productivity and profitability. Contact us right now for the best rate and to enhance your recycling process.

Why Choose our Copper Recovery System

By choosing our Copper Recovery System, you are associating yourself with a system known for its high efficiency and high recycling rate. Our machines are specifically designed to improve copper recovery rates, hence enhancing your production and profit.

We are committed to implementing modern, advanced technologies into our designs to ensure longevity and constant performance. You have access to ongoing knowledgeable support with our system, assuring top performance.

By selecting our solution, you are investing in a sophisticated, trustworthy system capable of meeting the stringent requirements of modern recycling operations.

You will smile after using our machine.

How to Get Copper Recovery System

Enquire about our offerings, and let us assess your needs, identify the right Copper Recovery System, and organize transport and setup.

01.

Inquiry and Consultation

Contact us for a further explanation of our Copper Recovery System, which is designed to improve your recycling efficiency using innovative and dependable solutions.

02.

Customization and Quotation

Inquire about a customized configuration and receive a complete quotation for a Copper Recovery System that meets your specific needs.

03.

Order Confirmation and Manufacturing

We will manufacture the machine with a responsible and rigorous attitude after purchase confirmed focusing on precision and great craftsmanship.

04.

Delivery and After-Sales Support

We will send the machine to the reputable shipping company and track the shipping information to make sure the machine can be taken by customers successfully. We also provide careful after-sales to solve the problems you met during the use.

FAQs

The system is adept at handling a broad spectrum of copper materials, including diverse types of wires and cables, all kinds of scrap radiators, and also copper winding wire for efficient copper granules recovery.

Designed for optimal performance, say 99.9%, BSGH Granulator system ensures substantial recovery of copper, utilizing sophisticated separation technologies for minimal loss.

Available in many models, the system’s capacity varies to accommodate different volume requirements. We advise discussing with our staff specific needs for a tailored solution.

Yes, the system is engineered for ease of use with straightforward controls and is constructed for durability with minimal maintenance needs.

We provide extensive support, including installation guidance, operational training, and maintenance tips, along with responsive customer service to ensure ongoing, efficient operation.

Lets Tell Us About Your granulator machine Needs

Share your wire granulator machine specifications with us. We will create specialized processing plans aimed at boosting your recycling capacity and output quality.

- Whatsapp/Viber: 008613772508206

- Email: coppergranulator@bsghrecycling.com

- Website: https://bsghgranulator.com/