Introduction

South America is well-known for its rich natural copper reserves, especially in countries such as Chile and Peru, which are leading in the production of primary copper. However, copper is a metal material with a high recycling value. Even after copper products are discarded, the copper materials in them can be recycled and reused with almost no performance loss.

The copper recycling industry has a rich history. With the rising demand for copper and people’s increasing environmental awareness, even in copper-rich South America, many countries are now investing a lot of resources in copper recycling to support sustainable development.

This article will introduce the development of copper recycling in South America and the hot-selling professional copper recycling equipment, helping customers who want to start a copper recycling business to quickly understand this industry.

South America Copper Scrap Market Overview

The development of the South American copper scrap market is influenced by key factors such as market demand, international copper prices, and national policies.

1. Market Demand

Copper is used in many fields, including electricity, energy, machinery, metallurgy, transportation, etc. These industries rely heavily on copper as a raw material, so their development has also driven copper demand. Nowadays, with the rapid development of industries such as electricity and transportation, copper demand is also increasing. However, if we only rely on mining new copper mines, it will not only fail to meet the huge market demand, but also the copper reserves will become less and less. Therefore, recycled copper has become a very important source of copper materials, accounting for about 35% of the total copper consumption. This shows that recycled copper has a huge sales market and it’s a stable business to recycle copper.

2. International copper prices

A detailed analysis of copper price trends over the past 15 years shows that copper prices have been rising overall, consistent with the rapid development of the copper recycling industry. Rising copper prices have attracted more recyclers to the market, bringing new impetus to the industry. The influx of new players has also driven the demand for more advanced and efficient recycling technologies, promoting the continued development of the copper recycling industry. In 2024, despite slight declines in May and July, copper prices climbed from $3.70 per pound at the beginning of the year to $4.20 per pound in November. This overall upward trend shows that market conditions for copper recycling are strong, indicating a promising outlook for continued industry expansion.

3. National Policies

With the rising demand for copper and the gradual shortage of copper resources, South American countries are paying more and more attention to the sustainable development of copper and starting to use recycling methods instead of new copper mining. Brazil, Argentina, and others are implementing policies and incentives to minimize waste and environmental degradation. For example, incentives for companies that actively recycle materials have increased private-sector investment in copper recycling facilities, which has a positive impact on the scrap copper market.

4. Predictions for future development

We believe that the proportion of recycled copper in South America’s copper raw material supply will gradually increase in the future, promoting the vigorous development of the copper recycling industry.

- First of all, although South America has relatively abundant copper resources compared to other regions, the global demand for copper will increase in the future. Recycling of scrap copper has the advantages of low cost, high profit, and environmental protection. It can reduce the mining of new copper mines while bringing benefits to recyclers and avoiding waste of resources.

- Secondly, copper price will continue to rise in the future, bringing more profits to recyclers and stimulating more people to join the ranks of copper recycling.

- Finally, the encouragement of policies of various countries will gradually increase the recycling rate of scrap copper and further promote the development of the scrap copper industry.

IN SUMMARY, the copper recycling market in South America is expected to grow strongly, driven by increasing demand, favorable copper prices, and supportive government policies. With the emergence of more advanced recycling technologies and equipment, copper recycling has gradually become a more efficient, labor-saving, stable, and profitable business.

Ⅲ. The Most Common Copper Scrap Materials In The South American Market

Scrap Cables: Cables are widely used in all places where electricity exists, so the amount of scrap cables is very large. Cables use copper or aluminum wires as conductive metal cores, copper wires are usually more durable than aluminum wires and have a higher recycling value. The higher the copper content of cables, such as square cables, communication cables, etc., the higher their recycling value will be.

Scrap Motors: From small household appliances to large industrial heavy machinery, they are all driven by electric motors. Electric motors are made of metals such as copper, aluminum, and iron, they can be recycled even after being discarded. Generally, motors with copper windings in the stator and rotor are more profitable to recycle.

Waste Radiators: Radiators are usually made of copper or iron pipes wrapped in aluminum foil. They are essential in cars, air conditioners, and various systems that require cooling. Copper pipes, iron pipes, and aluminum foil can all be recycled.

Waste Transformer: Transformer is a common power equipment that can convert electricity from one voltage level to another. It plays an important role in the power transmission grid, industry, construction, and other fields. Transformer has high copper winding content, and recycling these copper windings can bring a lot of profits to recyclers.

Scrap Compressors: Compressors can be found in refrigerators and air conditioners. They have very hard metal shells, making them more difficult to recycle than other copper waste, but if their shells can be removed, the rich copper inside the compressors can bring huge profits to recyclers.

Ⅳ. TOP 10 Hot-selling copper recycling equipment in South America

BSGH Granulator is committed to providing high-quality copper recycling machines to recyclers all over the world. Over the years, we have conducted extensive market research around the world (including South America) and have a deep understanding of the recycling market in various places. We have established strong partnerships with many customers in South American countries. Based on our experience, we recommend the following copper recycling equipment as the best-selling and most suitable options for South American recyclers.

1. BS-AN125 wire stripping machine

BS-AN125 wire stripping machine is a heavy-duty industrial wire stripping machine that can handle wires with diameters ranging from 2 to 120 mm. Its sturdy structure and sharp and durable blades enable it to cut through the hard insulation layers of high-hardness cables, such as armored cables, single-strand hard wires, submarine cables, etc. Its powerful stripping capacity makes it popular among recyclers in South America.

2. BS-D75 copper granulator machine

BS-D75 copper granulator machine is a small machine that is popular all over the world. It is specially designed for waste wires and cables and can process 50KG-70KG per hour. Although it has a small processing capacity and the machine price is low, we chose high-quality thickened steel plates to make the machine body, and high hardness and high wear-resistant steel to make the blades, making it as strong and durable as the large models. We use the most advanced airflow sorting technology to greatly reduce the copper loss rate of BS-D75, achieving a recycling rate of 99.99%. If you don’t have a large number of waste cables, or if you are just entering the copper recycling industry, then our BS-D75 copper granulator machine is very suitable for you.

3. BS-N125 copper wire recycling machine

BS-N125 copper wire recycling machine is a medium-sized copper granulator with a processing capacity of 300KG/H-500KG/H. It can process waste cables into pure copper granules and plastic granules with bright surfaces to achieve a higher sales price. It can recycle almost all kinds of waste cables, copper wires, aluminum wires, and even miscellaneous wires with very low copper content can be processed well, with better effect for cables with a diameter of less than 25mm. Even if you have some special types of waste cables such as iron cables, very thin wires, etc., you can easily recycle them by adding auxiliary equipment.

4. BS-F3000 copper cable granulator

The BS-F3000 is the largest standard model among all our copper granulators. It represents the highest efficiency in recycling waste cables and can process 1.2T-1.5T of raw materials per hour. It combines excellent performance, high durability, and high safety, and has a very strong processing capacity. It can not only process various waste cables but also radiators and transformers. The BS-F3000 copper cable granulator is very suitable for recyclers with a large number of waste cables and a stable source of cables and is an ideal equipment for large recycling stations and scrap metal trading centers throughout South America.

5. BSM-50 electric motor cutting machine

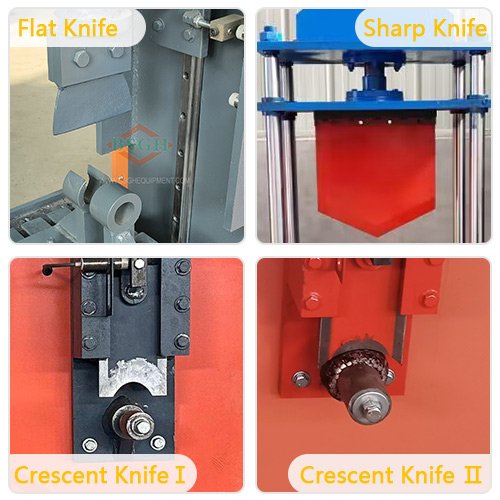

If you want to quickly disassemble the motor housing when recycling scrap motors, you can try our BSM-50 electric motor cutting machine. It is specially used to cut various electric motors with a diameter of less than 500mm. This machine mainly has a sharp knife and a flat knife. When using it, you can use the flat knife to cut the motor housing and use the sharp knife to cut the motor stator into two halves.

6. BSM-40 electric motor recycler

The BSM-40 electric motor recycler has one cutting part and 3 pulling parts, for taking out the copper windings from the motor stator after removing the housing. It is suitable for almost all motors with a diameter of less than 500mm. With powerful functionality, the BSM-40 features a dual-flow pump, allowing the hydraulic clamp to work simultaneously with any other part, greatly improving motor recycling efficiency. The BSM-40 and BSM-50 are a perfect match and are the “golden partner” to simplify motor recycling.

7. Double shaft shredder

Double shaft shredder is an industrial equipment that can effectively reduce the size of various raw materials to reduce floor space, transportation costs, or facilitate further processing. It continuously squeezes and shreds the materials through two shafts rotating in opposite directions and the blades on the shafts. Double shaft shredder has a wide range of applications, it can not only be used as a pre-shredder for cable granulators to improve recycling efficiency and protect the blades of the main crusher but also as a single machine to process raw materials such as tires, wood, plastics, metals, etc. We have double-shaft shredders of various sizes and processing capacities, and we can also flexibly customize the blade materials. This powerful shredding ability and flexibility make our double-shaft shredders selected by many South American customers.

8. BS-1200P copper and aluminum separator machine

BS-1200P copper and aluminum separator machine is designed to recycle regular, flat radiators. It can directly process 1-2 layers of waste radiators. If you need to process multiple layers of radiators, you can first use a band saw to cut them into 1-2 layers, and then feed them into BS-1200P for processing. Our machine can process radiator copper tubes with a center distance of 19mm, 21mm, and 25mm, covering the most common radiators on the market. If you have radiators of other sizes, we can also flexibly customize them according to your needs.

9. Plasma Compressor Case Cutter

Plasma Compressor Case Cutter can cut the hard outer shell of the compressor with a length ranging from 15cm to 55cm and an outer diameter of 12cm to 26cm, to facilitate further recovery of copper winding inside. It is very efficient and only takes about 30 seconds to process a compressor, and the whole process is carried out automatically in a closed environment. This high efficiency and high safety make Plasma Compressor Case Cutter a hot seller in Chile, Brazil, and other South American countries.

10. Excavator Rotating Grapple

Excavator rotating grapple is a front-end attachment mounted on an excavator, mainly used to grab various waste materials. It consists of 4 or 5 heavy-duty steel claws, which you can flexibly control through the excavator to open, close, or rotate 360 degrees, easily achieve large-scale feeding and save labor costs. We have a variety of durable excavator rotating grapples, suitable for various sizes of excavators from small to large.

Ⅴ. Conclusion

The South American copper scrap market has a good status quo and broad development space. Recycled copper has a wide sales market and high prices. Many countries in South America have corresponding incentive policies to support copper recycling, making this business both stable and profitable.

BSGH Granulator has cooperated with many customers in South America and provided them with high-quality professional equipment for their recycling business. In this article, we list 10 best-selling copper recycling machines in South America for reference by recyclers. If you are interested in our machines, please send us your inquiry and we will send you more machine details.

- Email: coppergranulator@bsghrecycling.com

- WhatsApp: 008613772508206

- Website: https://bsghgranulator.com

- https://3t-motorrecycle.com/autor-starter-motor-recycling-machine/