Copper Wire Recycling Machine | Maximize Scrap Value with High-Efficiency Recycling

– Best copper wire recycling solutions, high efficiency and low energy consumption

– Advanced air separation, vibration separation, and other physical technologies

– More than 100 models for you to choose from

– The praise rate exceeds 99.8%

– Your reliable copper wire recycling machine manufacturer

about copper wire recycling machine

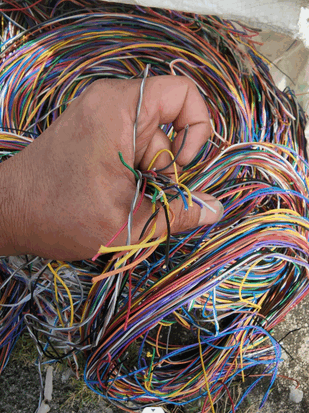

Copper Wire Recycling Machine is specially designed to efficiently recycle almost all types of scrap cables. It crushes cables first and then separates copper from insulation materials with high precision, maximizing the recovery value of scrap wires. The machine is ideal for recycling a wide range of cables, including automotive wires, household wires, communication cables, etc., and performs especially well with cables less than 25mm in diameter.

- Advanced Technology Designed for Maximum Profit

- From small home models to heavy industrial models, there is always one that can perfectly meet your needs.

- The efficient dust collection system will collect all the dust during the recycling process, ensuring 0 pollution, making our machines meet global environmental standards.

- Combining advanced air separation, vibration separation, electrostatic separation, magnetic separation, and other technologies, it can quickly and accurately separate copper-plastic mixtures.

Industrial copper wire recycling machine features

-

99.99% Copper Recovery Rate

-

CE Certified & Eco-Friendly

-

100+ Models for Every Need

-

Compact Design with Space Optimization

-

Free Custom Layout Service

-

Support customized 3-5T/H

Find the Perfect copper wire recycling Machine for Your Business

Copper wire recycler from BSGH Granulator comes in different shape and types, from small to big, home to industrial use, every of our model has it’s features and advantages, you can choose according your requests. Our wire recyclers was mainly divided into D series and N series, small and big granulator, we will have a look about our wire recyclers below and check each type features and advantages in order to faciliate your choose.

BS-F3000 copper cable granulator

This model is the biggest among N series copper wire recycling machines, widely used by our overseas customer, process about 800-1500KG/H.

ECO1000 copper cable recycle machine

ECO1000 have 2 air separator systems, is the basis of the big cable recyling equipment, have 4 small table vibrator and capacity about 700-1200KG/H.

BS-N130 copper wire separator

BS-N130 is the most popular granulator machine in middle sized scrapyard, it has preshredder and one air separator system, processing about 400-600KG/H.

BS-N125 copper recycling machine

BS-N125 is the middle copper wire recycling machine, have 2 small vibrator table and 1 air separator system, capacity about 300-500KG/H.

BS-D60 copper wire recycle machine

BS-D60 is the basis model of D series, capacity same with BS-N125 about 300-500KG/H, for processing different types of cable, their processing capacity are also different.

BS-D30 copper wire recycler

This model is the best cost performance granulator, cheaper price but higher processing capacity about 300KG/H, one intergrated machine, easy to operate.

BS-D80 copper wire separator

This model have a split type of the main body, split bigger crusher #800 and preshredder with one bigger air separator system, process about 500-800KG/H.

BS-D20 copper wire recycle machine

BS-D20 also very popular in customer, cheap price but bigger capacity about 200KG/H, suitable for most of customer, affordable and higher efficiency.

BS-D75 copper wire recycle machine

BS-D75 is the smallest industrial granulator machine, usd7800 cheap price but perfect performance, it’s one really small machine can help you earn money.

Raw materials and final products

Our copper wire recycling machines can recycle all kinds of scrap cables, no matter high copper content or low copper content, pvc or rubber outer sheath, our machine can process it well and help you get the pure copper and plastic.

how copper wire recycling machines works?

Here are some working videos of our copper wire recycling machines for your reference. You can see that each of our machines has an excellent separation effect. The purity of the recycled copper particles is as high as 100%, and they can be sold directly at a high price without the need for secondary processing.

Why BSGH Granulator?

√ More than 25 years of experience in copper wire recycling machine manufacturing

√ Professional technical team to help you solve all problems related to the machine

√ Flexible configuration, we can customize different auxiliary equipment for you according to different cable types and quantities

√ Over 70% market share in China

√ Sales footprint covers more than 80 countries and regions around the world

√ Formal banking transactions, ensure the safety of your funds

√ One-year warranty and lifetime online technical support service

copper wire recycling machine Components and optional parts

Copper wire recycling machine is commonly consist of the main parts and optional parts. Main parts is the must part of the copper wire recycling machines, optional parts is you can choose or not according your scrap raw material condition.

main parts

1. Main crusher: The crushing system is the first process of copper wire recycling machine. Main crusher is mainly used to crush the scrap cables into 3-5mm copper-plastic mixture for subsequent recycling steps.

2. Air separator: Air separator is the key component of the separation system. It can use the wind and gravity to separate copper particles and plastic particles of different weights.

3. Vibration table: The second step of the separating system, which uses the different vibration frequencies of the two substances to efficiently separate copper and plastic.

Optional parts

Magnetic Separator

If you need to process wires that contain iron, then adding a magnetic separator to your equipment is essential. The magnetic separator will sort the iron from all the mixed particles, ensuring that the final product is not affected.

Electrostatic separator

Electrostatic separator is very effective in processing slim wires with a diameter of less than 1mm. It is placed in the plastic outlet and can separate the final product again before being discharged from the machine, separating the slim copper wires that the air separator cannot sort out.

Pre-shredder

Pre-shredder can pre-shred the cables into 5-25cm strips before they enter the main crusher. It not only protects the blades and prolongs the service life of the copper wire recycling machine, but also effectively increases the processing capacity.

Certification

All our copper wire recycling machines manufactured by BSGH Granulator have CE certification.

FAQ

Do you provide copper wire recycling machine accessories?

Yes, we will provide you with free blades, screens, and a toolbox, which is enough to support you for a long time.

Can your copper wire recycling machine process aluminum wire?

Yes, our machine can also recycle aluminum wire well. When you need to process both copper wires and aluminum wires, please put them into the machine separately.

Can I process the plug wires with your machine?

Please try to avoid putting the plug wires directly into the machine, because it will harmful to blades and make blades easy dull; you can cut off the plugs before feeding, or add a pre-shredder to your copper wire recycling machine.

I have a small amount of waste cables with a diameter greater than 25mm. Can I use your machine to process them?

Yes, our machine can process a small number of cables with a diameter greater than 25mm. If the quantity is large, please use it together with a wire stripping machine or dual shaft shredder.

Do your copper wire recyclers use the dry recycling method or the wet recycling method?

Our copper wire recycling machine use the most advanced dry separation technologies on the market, such as air separation, vibration separation, magnetic separation, and electrostatic separation; we also have water recycling granulator machine, if you want, you can consult with our staff.

Do you provide installation and training services for your copper wire recycling machine?

Yes! We offer remote installation guidance and on-site support. We also provide comprehensive training documents to ensure you can start production smoothly.

How do I choose the right model?

Contact our experts for a free consultation. We'll recommend the best model based on your material type, processing volume, and budget.