Double Shaft Shredder factory

Double shaft shredder are used for industrial purposes to shred materials using two rotating shafts. They operate at slower speeds but with higher torque, making them effective for breaking down tough materials into smaller pieces.

Shredders mainly for break down materials into smaller, more manageable sizes. They’re crucial in the process of recycling materials like paper, plastic, metal, and other waste products.

Shredder/Crusher

Double Shaft Shredder / scrap metal shredder for sale

The double shaft shredder machine is a shearing shredder with two main shafts rotating in opposite directions, so it’s also called 2 shaft shredder and each shafts are equipped with multiple serrated blades and the spacer between them. When running, the main shafts roll the material in the shredding chamber into the gap between the two shafts, and cooperate with high-quality blades to continuously shear and tear, achieving the purpose of material size reduction. The number, size, and configuration of the blades can be customized according to the specific material you want to process, to achieve different shredding effects.

- Built for heavy loads – Process bulky materials like car shells, pipes, and carpet rolls without jamming

- Durable, long-lasting blades – High-grade steel cutters reduce maintenance downtime

- Powerful & efficient – High-torque motors ensure smooth shredding at lower energy costs

- Versatile material handling – Shred plastics, wood, paper, rubber, and more in a single machine

- Flexible design – We can design blades of different sizes and thicknesses according to your raw materials. If you require a specific motor brand and power, we can also customize it

Industrial double shaft Shredder videos

Warning: Undefined array key "autoplay_speed" in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/ultimate-elementor/modules/video-gallery/widgets/video-gallery.php on line 2078

heavy duty industrial double shaft shredder technical data:

BSGH Granulator factory heavy-duty industrial 2 shaft shredder have from small to big, double shaft shredder mainly robust machines designed for high-capacity shredding of various materials, typically used in industrial settings or facilities. These shredders are capable of handling large volumes of materials such as plastics, metals, papers, textiles, and more. They’re engineered with powerful motors, durable blades, and sturdy construction to efficiently shred bulky items, ensuring the effective reduction of materials into smaller pieces for recycling, disposal or further processing.

| Model | Blades Specification | Power | Blades Quantity | Reducer | Diamension(MM) |

|---|---|---|---|---|---|

| #600 | Φ250*20 | 15KW*2 | 30 | ZQ400 Series | 2800*1400*1900 |

| #600 | Φ300*30 | 22KW*2 | 20 | ZQ500 Series | 2800*1400*1900 |

| #800 | Φ350*25 | 22KW*2 | 32 | ZQ650 Series | 3700*1540*2200 |

| #800 | Φ400*40 | 30KW*2 | 20 | ZQ650 Series | 3700*1540*2200 |

| #1000 | Φ400*30 | 30KW*2 | 33 | ZQ650 Series | 3860*1550*2350 |

| #1000 | Φ400*40 | 37KW*2 | 25 | ZSY315 Series | 4000*1600*2350 |

| #1000 | Φ400*50 | 45KW*2 | 20 | ZQ850 Series | 4200*1650*2350 |

| #1200 | Φ400*40 | 45KW*2 | 30 | ZSY355 Series | 4600*1900*2450 |

| #1200 | Φ400*50 | 55KW*2 | 24 | ZSY400 Series | 4600*1900*2450 |

| #1400 | Φ500*40 | 55KW*2 | 35 | ZSY400 Series | 5200*2100*2600 |

| #1400 | Φ550*60 | 75KW*2 | 23 | ZSY450 Series | 5300*2200*2600 |

| #1600 | Φ500*40 | 75KW*2 | 40 | ZSY450 Series | 5500*2100*2750 |

| #1600 | Φ600*60 | 90KW*2 | 26 | ZSY500 Series | 5800*2300*2800 |

| #1800 | Φ650*50 | 90KW*2 | 36 | ZSY500 Series | 6000*2400*2950 |

| #1800 | Φ700*60 | 110KW*2 | 30 | ZSY560 Series | 6000*2500*3100 |

Note: All the above data are variable. According to different materials, different discharging requirements and output, we will make different configurations for customers; different raw materials will have different sizes and thicknesses of the blades, so for specific machine details, please contact our sales manager.

How to order the right shredder from BSGH Granulator?

In order to let you get the suitable shredders from us, pls don’t hurry up to get the machine price, because for different kinds of material and different size, your demands for the output size, even if the same configuration machine, price are not same, first we should assure you buy the right one which can fit for your function well.

- Pls contact our staff first.

- Send them your raw material picture and told them your requests, such as capacity, output size and your application fields.

- After we have a clear intention about your demands, we will calculate and quote you the best price with best quality.

- Order with us to pay 30% in advance and 70% before arrange shipping.

Get Factory Price Today.

BSGH Granulator provides you solutions for double shaft shredder machines, various designs and capacities suitable for different types of raw material shredding.

Best Cost Performance.

High-performance double shaft shredder selection by application

Our double-shaft shredder machine is a versatile and multifunctional piece of equipment designed for efficiently shredding a wide range of materials. This makes it an ideal solution for recycling facilities, waste processing plants, and manufacturing operations seeking to reduce material volume and facilitate further recycling or disposal.

Double shaft shredder for scrap cables

Double shaft shredder can process cables into 5-25cm, making the subsequent recycling process faster and more efficient. Adding a dual-shaft shredder to your copper granulator can improve recycling efficiency and protect the main crusher blades.

Double shaft shredder for plastic and tire

Our double-shaft shredder machine is multifunctional equipment capable of shredding a wide variety of materials. It can also efficiently process scrap plastics such as plastic bottles, rubber, tires, and many other waste materials, offering an effective solution for recycling and waste reduction.

Double shaft shredder for clothing

The Multifunctional dual-shaft clothing shredder can shred a variety of fabrics: old clothes, carpets, shoes, and other items into manageable sizes without the machine becoming clogged or tangled in the spindle.

Double shaft shredder for metal

The scrap metal shredder is equipped with two motors and two reducers, ensuring low speed and high torque, easily crushing copper, aluminum, steel, and other metals.

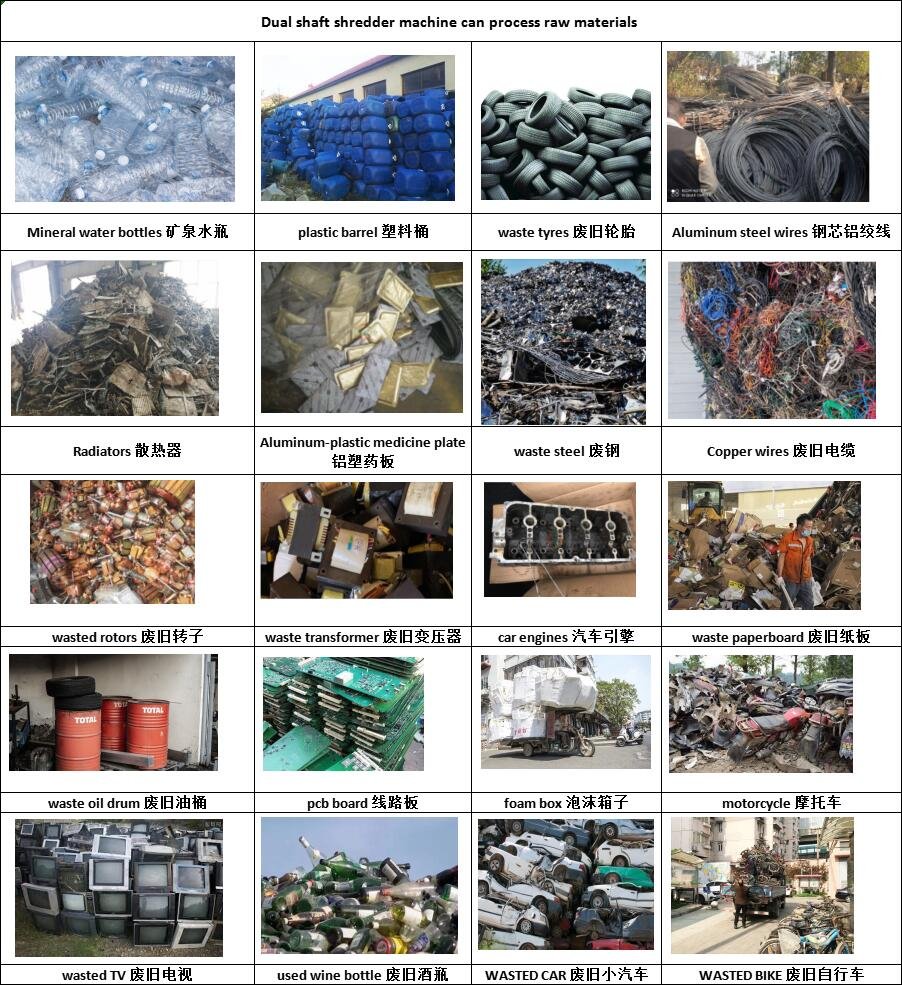

Application of industrial double shaft shredder machine:

Following is our double shaft shredder machine application scrope, wide processing range and big capacity.

- Various hollow containers: plastic beverage cans, plastic barrels, metal barrels, packaging boxes, and packaging barrels.

- Scrap household appliances: TV, washing machine, refrigerator shells.

- Pipelines: large pipes, pipe fittings, PE pipes.

- Scrap templates: wooden pallets, plastic pallets, forklift pallets.

- Scrap tires: small car tires, truck tires.

- Scrap metals: car shells, aluminum alloys, scrap aluminum castings, engine shells, lead, and steel plates with a thickness below 5mm.

- Waste from life: Food waste, household waste, animal carcasses, RDF derivatives, medical waste, biogas residues, and garden waste.

- Rubber head materials, paper mill rope structure characteristics.

Features of industrial heavy duty double shaft shredder

- Shredder Main Body: The main body of the equipment is welded with high-quality steel plates, stress-relieved, and processed as a whole, ensuring stability under prolonged heavy loads.

- Shredder Blades: Double shaft shredder blade is made of specially forged alloy steel blanks, processed precisely, and undergoes multiple heat treatments and low-temperature cryogenic treatments to ensure consistent toughness and hardness for repetitive use, ensuring cutting performance and longevity. The fixed blade utilizes a patented hook-type installation, optimizing tool replacement efficiency for easier maintenance.

- Bearings / Seals: The bearing seat employs a patented detachable design, enabling quick disassembly of components like moving blades, fixed blades, and bearings, facilitating tool maintenance and replacement. The unique sealing structure effectively prevents contact between crushed materials and grease, protecting bearings and gears even when handling liquid materials.

- Shredder Shaft: Manufactured using high-strength heavy-duty steel to provide robust power support for cutting in coordination with the blades.

- Working Process: Materials enter the interior of the box through the feeding system, gathered by the two rotor shafts mounted on the box. These shafts rotate alternately inward or outward, each equipped with a row of specially shaped shredding blades. The materials undergo cutting, squeezing, and tearing actions by these shredding blades, resulting in shredded small-sized materials discharged from the bottom of the box.

Installation of heavy duty double shaft shredder

Machine Installation: Place the machine on a flat and sturdy surface, adjust it to be level, and ensure it is not tilted.

Installation of Power Cord

- The power cord of the machine uses a three-phase three-wire power supply, with a voltage of 380V and frequency of 50Hz.

- L1, L2, and L3 are the live wires. 2.2 If the direction of rotation of the blade axis is reversed after startup, interchange any two of the above power cord wires L1, L2, L3.

Machine Operation

1: Pre-start Preparation

- Check and add an appropriate amount of gear oil, labeled as 220# gear oil, and ensure that the lubricating oil for the reducer reaches the oil level window.

- Check for any foreign objects inside the shredding chamber.

2: Startup Procedure

- Rotate the emergency stop button clockwise.

- Press the F1 button on the numerical control display screen to start the machine operation.

- Press the emergency stop switch to stop all machine operations.

Matters Need Attention

1: Feeding Method

A conveyor belt should be used for uniform and steady feeding. If there is no conveyor belt when using a claw machine or manual feeding, attention should be paid to the following:

- Each time feeding should not exceed the maximum load capacity of the equipment, and do not fill the hopper (original machine hopper) full with materials at once.

- There should be a certain interval between each feeding to avoid feeding too quickly, which may cause the equipment to be unable to crush materials and result in jamming.

- If jamming occurs due to excessive and rapid feeding, immediately reverse the machine for a few turns and then forward again. Repeat until the machine operates normally before feeding again.

2: Daily Maintenance

- Check the lubricating oil in the gearbox every month to ensure it is at the oil level window. After using for a certain period, replace the gearbox gear oil based on its actual condition to extend the lifespan of the gearbox.

- Inject an appropriate amount of lubricating oil into the oil nozzles of the four bearing seats every 50 hours to ensure the bearings do not lose oil.

- When the machine is not in use, it should be running empty for a few minutes each shift (alternating between forward and reverse rotation) to clean out any residue as much as possible.

Troubleshooting

| Fault Description | Reasons | Solution |

|---|---|---|

| Indicator light does not turn on when main power switch is opened | Poor power connection | Check power supply |

| Machine vibrates during operation | Machine installation is not leveled | Adjust and level the machine |

| Temperature of shredding chamber rises during machine operation | Blunt blades | Replace blades |

| Machine speed gradually slows down during operation | Low voltage | Check power supply |

what determine the industrial double shaft shredder machine price?

The dual shaft shredder machine is primarily designed for industrial purposes, the price of an industrial double shaft shredder machine can be determined by several factors:

- Size & Capacity: Larger and higher-capacity machines generally cost more due to the increased material and manufacturing costs.

- Motor Power: Higher horsepower motors are more expensive but offer greater torque and processing power.

- Automation Level: Machines with advanced automation features, such as PLC controls and automatic feed systems, tend to be more costly.

Quality and Construction: Machines made from high-quality materials, robust construction, and durable components often come at a higher price point. - Brand and Manufacturer: Well-known brands or manufacturers with a reputation for reliability and quality may have higher prices compared to lesser-known or generic brands.

- Customization Options: Shredders that offer customization options for blade types, sizes, materials, motor and other features might have a higher price due to the versatility they provide.

- Technology and Features: Advanced technology, automated features, safety enhancements, and energy efficiency can contribute to higher prices.

- Maintenance and Support: Machines that come with warranties, after-sales service, and technical support might have higher initial costs but can provide long-term value.

- Market Demand and Competition: Prices can also be influenced by market demand, competition between manufacturers, and ongoing promotions or discounts.

Here are some general price ranges for double shaft shredders:

Small Shredders (5HP – 10HP): $5000 – $20,000

Medium Shredders (20HP – 50HP): $15,000 – $50,000

Large Shredders (75HP – 150HP): $60,000 – $150,000

Industrial Shredders (200HP+): $200,000+

It’s important to note that these are just estimates, and the actual price of a double shaft shredder can vary significantly depending on the specific factors mentioned above. To get a more accurate quote, it’s recommended to contact manufacturers(BSGH Granulator) and request a personalized estimate based on your specific requirements.

Order Industrial Double Shaft Shredder now

FAQs about dual shaft shredder

Double shaft shredders are versatile and can process various materials, including plastics, wood, paper, rubber, and metals.

Modern double shaft shredders often integrate energy-efficient technologies to minimize power consumption during operation.

Regular maintenance, including blade sharpening and lubrication, should be conducted according to the manufacturer’s recommendations to ensure optimal performance.

Yes, these shredders are designed to process large items efficiently, reducing them to smaller, manageable pieces.

BSGH Granulator manufacturers offer customization options to tailor the shredder’s specifications to handle specific materials or operational requirements.

Best Configurations | Good Quality Blades | Pure Copper Motor