Durable

Excavator Rotating Grapple Manufacturer

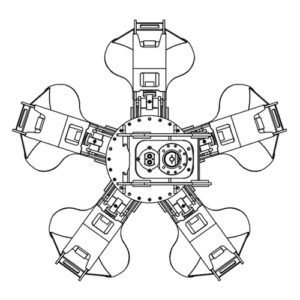

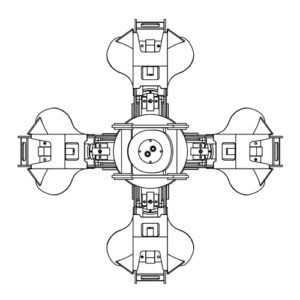

Excavator rotating grapple is a kind of front-end attachment specially used for grabbing scrap materials used with excavator. It consists of five or four curved steel claws, which can open and close under the control of the excavator, clamp the scrap materials and transport them.

Our excavator rotating grapple is mainly assemble with our copper wire granulator machine, it can help you feeding material easily and automatic.

Excavator Rotating Grapple Types

Hydraulic excavator rotating grapple are divided into: hydraulic non-rotating grabbers and rotating hydraulic grabbers; hydraulic non-rotating grabbers can be used without modifying the excavator pipeline and hydraulic system (low-cost type); rotating hydraulic grabbers need to modify the excavator pipeline and hydraulic system to achieve the demand of 360-degree rotation (convenient, practical, high-cost type), we mainly talk about rotation type.

Excavator rotating grapple come in different sizes, and are used for different tonnage excavators, following we will learn more about different grapples.

Excavator Rotating Grapple from China - Excavator from 6~30T

Price: $5999~$18999

Excavator rotating grapple from BSGH Granulator come in different sizes, and are used for different tonnage excavators.

They are designed to handle various materials, such as scrap metal, wood, stone, and waste, can improve the efficiency and safety of loading and unloading operations, and are widely used in construction, mining, recycling, and forestry industries.

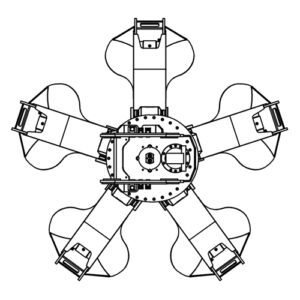

Optional: 4grabs or 5grabs

Excavator rotating Grapple Models

BSGH Granulator excavator rotating grapple is not only can help you to grab the scrap cables, but also can help you to take other scrap material just like wood pallet, scrap metal and others, it’s made for high efficiency and easy to use for customer, deeply loved by all customers.

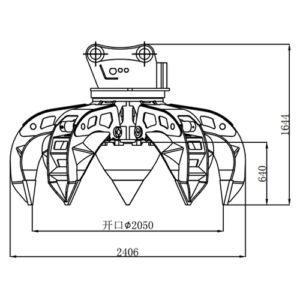

BS08 for excavator 18~30T

- Opening: 2050MM

- Volume: 1 Cubic Meters

- Height: 1644MM

- Width: 640MM

- Driving Pressure: 320kgf/cm2

- Driving Flow: 200~250lmp

- Weight: 2100KG

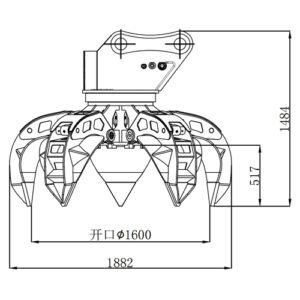

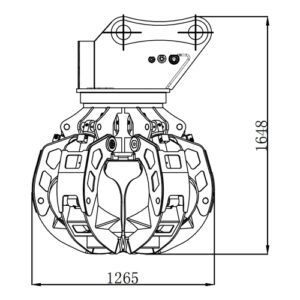

BS06 for excavator 9~16T

- Opening: 1600MM

- Volumn: 0.6 Cubic Meters

- Height: 1484MM

- Width: 517MM

- Driving Pressure: 320kgf/cm2

- Driving Flow: 200~250lmp

- Weight: 1000KG

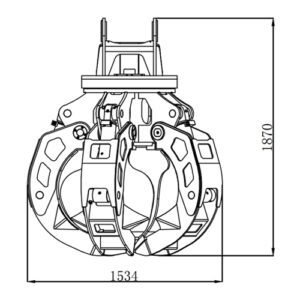

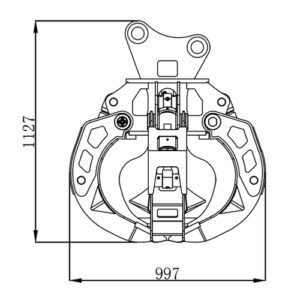

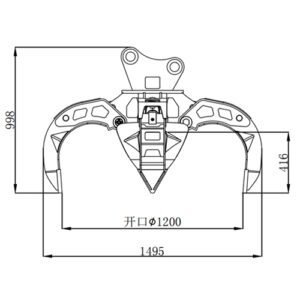

BS04 for excavator 6~9T

- Opening: 1200MM

- Volumn: 0.3 Cubic Meters

- Height: 998MM

- Width: 416MM

- Driving Pressure: 250kgf/cm2

- Driving Flow: 160~200lmp

- Weight: 355KG

What is an Excavator Rotating Grapple?

In essence, an Excavator Rotating Grapple is a versatile attachment designed to grasp, lift, and transport various materials on application sites. Its design incorporates a rotating feature, enhancing its functionality and adaptability. These grapples come in various sizes and configurations, catering to different excavator models and cable recycling needs. From single-arm to dual-arm grapples, each type offers unique advantages based on the scale and nature of recycling projects.

Components and Functionality

The primary elements of this grapple include sturdy claws or jaws, a rotating mechanism, hydraulic cylinders, and a robust framework. These components work harmoniously, allowing the grapple to grip and manipulate heavy loads efficiently.

Benefits of Using an Excavator Rotating Grapple

The excavator rotating grapple is a versatile attachment that streamlines scrap cable recycling. Its multifunctional design enables precise handling, sorting, and maneuvering of cables, boosting operational productivity while reducing labor costs.

How Does an Excavator Rotating Grapple Work?

The ingenious mechanism of the excavator rotating grapple involves a hydraulic system that provides a firm grip and precise control over the cables. This enables efficient loading, unloading, and sorting of cables, enhancing the overall recycling workflow.

Advantages of Excavator Rotating Grapples

The benefits of employing these grapples extend beyond efficiency. They include reduced downtime, enhanced safety, and increased profitability by optimizing resource utilization in the recycling process.

Let excavator rotating grapple make your scrap cable recycling easier

Discover how the excavator rotating grapple revolutionizes scrap cable recycling. Explore the benefits, techniques, and innovations that make this tool essential for efficient and eco-friendly recycling processes.

FAQ About excavator rotating grapple

Yes, most excavators can be fitted with rotating grapples, but it’s essential to ensure compatibility and seek professional guidance.

Routine checks on hydraulic systems, bolts, and hinges, along with lubrication, are vital for optimal performance and longevity.

Consider your excavator’s specifications, intended use, and the type of material you’ll be handling to determine the ideal grapple size.

Absolutely, their adaptability makes them suitable for various industries, including construction, forestry, and demolition.

While basic operation might seem straightforward, proper training ensures safe and efficient usage, minimizing risks.

Leave your doubts here to get what you care.