How does a Cable Granulator work?

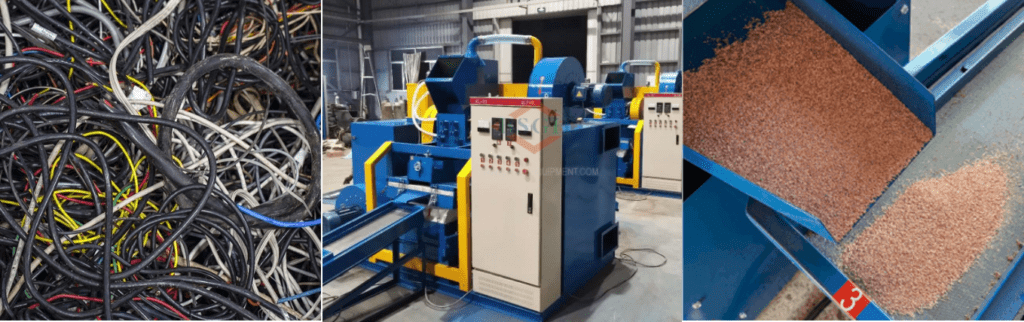

(Usage of cable granulator)

Maybe there are many people not known about cable granulator and the usage of the cable granulator machine.

Cable granulator machine is a machine that separates copper and plastic from waste cables, via the process of crushing and the principle of gravity separation to complete the whole process.

We recycle scrap cables to make money. There are many different machine and processing methods on the market. Which machine to choose is very important for us?

For scrap mixed cable and thin cable, copper wire recycling granulator machine is the best choice; for copper wire recycling, the purity of copper granules is an important factor to measure the value of copper wire recycling machine itself;

If you choose a poor quality copper granulator machine , may let your down and ruin your recycling career; if you choose a good quality copper cable granulator machine, you can not only make a lot of money, but also have a deeper understanding of this industry.

Therefore, understanding the principle of the machine and operating the copper granulator machine better will improve the purity of your copper granules to a certain extent and sell it at a better price.

Next, let us learn more about how cable granulator work.

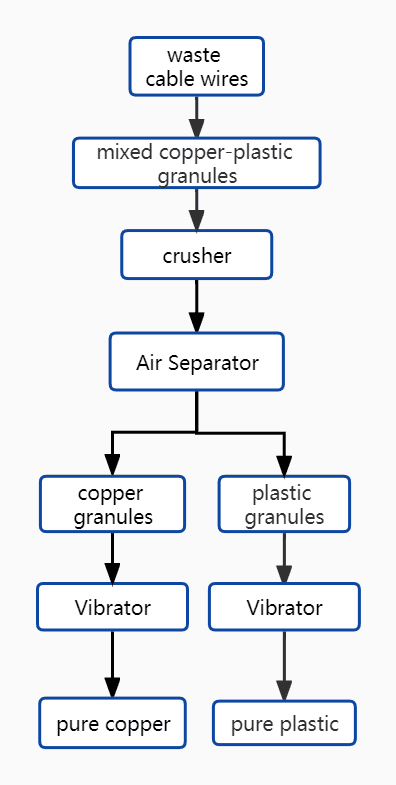

Before we know more about copper wire recycling machine, we need to know the principle of cable granulator machine first:

The main working principle of the dry copper wire granulator machine is to separate the metal and plastic skins through the air separation system and small vibrating screen after crushing, directly obtain the metal copper granules and plastic granules.

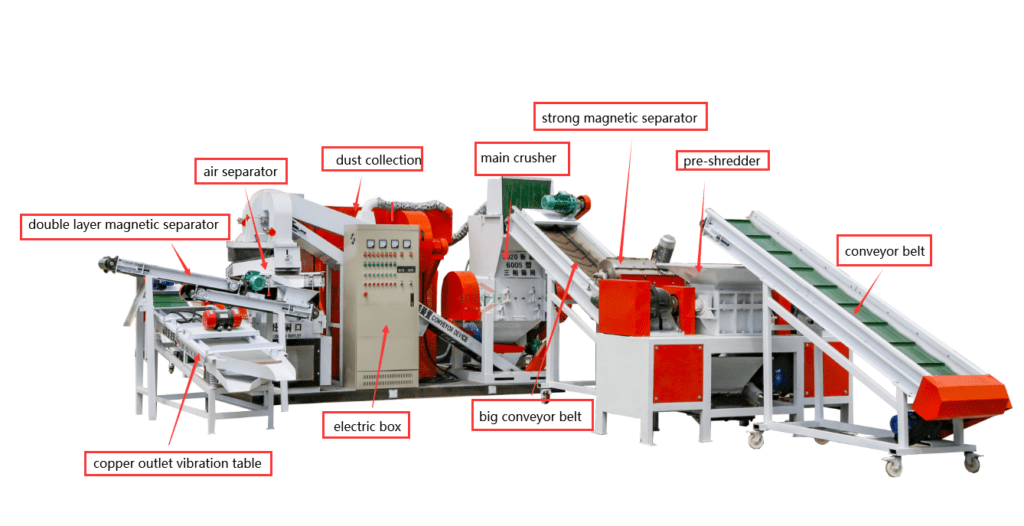

Generally speaking, the copper granulator machine is composed of three parts: main crusher, air separator and small vibration table, these 3parts are essential and you also can configure different equipment according to the characteristics of waste cables.

10steps Help You Know More The Cable Granulator Machine Working Process:

step 1: raw material preparing

First prepare the cables need to be crushed.

step 2: Classification

Classification according to different cable types, which will improve work efficiency.

step 3: machine connecting

Prepare three-phase power and connect it to the machine’s electrical box to power on the machine.

step 4:pre-shredder

The sorted cables are evenly fed into the pre-shredding and broken into small pcs about 5~20CM.

step 5: Convey

These roughly crushed cables will go directly to the crusher through the conveyor belt

step 6: crushing

The scrap cables will be processed into fine copper-plastic mixed particles by the shredder,

step 7: first separation

These mixed particles are transported to the air separation device for the first separation through the conveyor belt.

step 8: secondary separation

Next, the copper particles and pvc particles that have passed through the air separation equipment will be transferred to the small vibrating bed respectively, for secondary separation through vibration, and finally you will get pure copper particles and plastic particles, as well as less amount of copper-plastic mixture.

step 9: re-separation

A small amount of copper-plastic mixture can be put into the machine for re-separation.

step 10: electrostatic separation

Less amount of copper particles and plastic particles at the plastic end can be connected to electrostatic separator for secondary separation to achieve 100% copper recovery.

For Iron-Containing Cables

we recommend configuring magnetic separator to separate iron.

For Extremely Thin Copper Wires

It is necessary to configure an electrostatic separation device to separate the copper wires attached to the plastic skin due to static electricity.

BSGH is a professional cable granulator machine manufacturer, and can also provide copper wire recycling machines with different processing capacity and corresponding accessories. Surely if your machine have other configuration, maybe the processing will have a little change.

After the above introduction, I believe you have a deeper understanding of the working principle of the copper recycling machine, if you still have doubts, welcome to contact us.