Introduction

If you want to choose a high efficiency copper wire granulator, the primary consideration about recycling copper wire is the working performance, how well the equipment is made to work. Copper wire granulators are the most important part during copper recycling because they separate copper from the wasted copper wire, recover used copper wire into copper that can be used again. Reusing copper is important because it is good for the environment and the economy. Granulators adopt mechanical crushing, coupled with dust collection systems, to ensure a pollution-free process. Consequently, transforming worthless wire into valuable copper not only safeguards the environment but also yields substantial profits. It’s important to pick the right high efficiency copper wire granulator if you want to recycle more and earn more to live on.

This guide is primarily about important things such as the size of the machine, how effectively it works, how long it lasts for, and how easy it is to keep up. We prefer to help you find a granulator suitable for your recycling requirements. Our goal is to make your recycling process more effective and profitable for you

Understanding Copper Wire Granulators

Importance in the Recycling Process

Copper wire granulators are highly essential in the recycling business as they separate the copper wire from its insulation quickly and easily. It turns trash into useful recovered materials. This process is not only good for business, but it is also imperative for protecting resources: cuts down on the demand for more new resources, complement the demand for copper resource. Recovered copper can be used repeatedly in a variety of sectors grateful to the granulator. This system continuing resource utilization and supports sustainable resource management.

Types of Copper Wire Granulators Available

It’s wise to use suitable granulator which can better meet your needs. You can choose granulator through processing capacity, durability and so on. We list six best-selling granulators for your reference:

BS-F3000

99.9% recycling rate and 100% high-purity end products can compete with Euro machines.

Lower price compared with other same quality granulator.

Long service life(many of China customers have already used it for more than 10 years).

It can process almost all kinds of cable wires and it also can process scrap radiators.

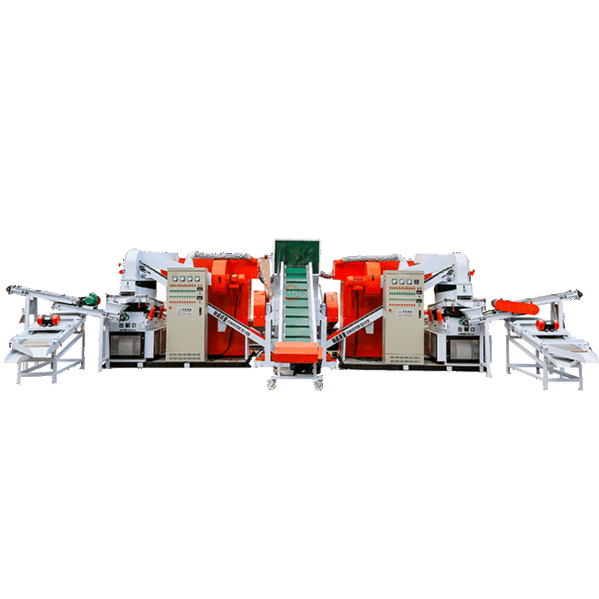

ECO1000

Large capacity can reach 1T/H

Configured with 4 small vibrating tables and 2 air separator systems.

99.9% copper recycling rate

Excellent blade quality and high-hardness spindle

BS-N130

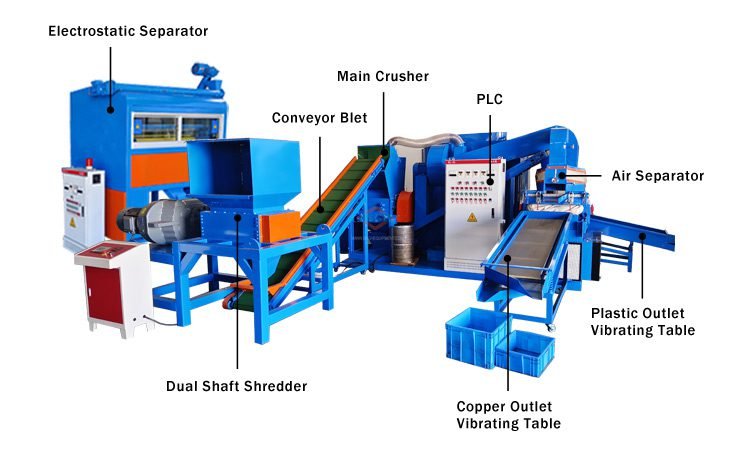

Assemble dual shaft shredder with higher efficiency. Dual shaft shredder will precrush the raw material into small pcs, this will convenient and reduce the pressure for next fine crusher.

Save more energy than other similar copper shredders.

Finish the whole processing automatically

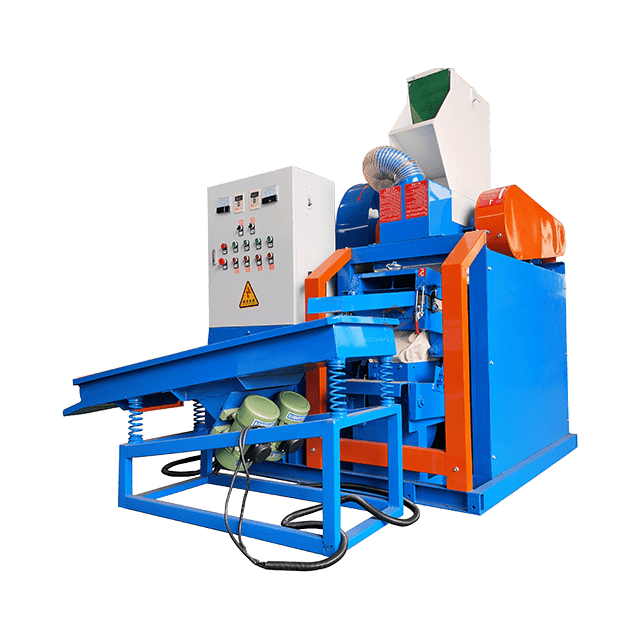

BS-D60

BS-D60 copper wire granulator is the highest cost-effective machine in similar structure in the market.

A medium capacity of about 300~500KG/H processing capability can meet your demands,

Lower noise than other granulators.

BS-D30

Beautiful and brief appearance, simple structure with air inlet filter, 300KG/H capacity is very suitable for small scrapyards

Best and professional service.

BS-D75

The smallest 3phase granulator, cheap price but good performance and recycling rate. one year warranty

The whole machine is structurally intact and working stably.

Customization service for single or three-phase according to your needs.

Key Features to Consider

Some important things to think about are the processing capacity, which tells you how much wire can be handled, and the machine’s ability to work with different types of insulation, which is important for getting the most copper back. It’s better to use more modern models that are better at separating things, use less energy, and make less noise and dust during operation. This makes the work situation better as well.

Here are some key considerations you need to think for as selecting a high-efficiency copper wire granulator to ensure sure you get the greatest value in of your finances and reach your recycling goals.

- Size and Capacity of the Granulator: The granulator should be the right size for the space you have in your building, and it should be able to handle the amount of work you need to do. How often do you want to recover copper wire? This will help you choose a machine that can do it without getting overloaded or breaking down frequently.

- Efficiency and Speed of Processing: The granulator’s efficiency has a direct effect on how productive your operations are. Look for tools that can work quickly without lowering the quality of the separation. This makes sure that materials are turned around faster and increases total throughput.

- Quality of the End Product (Purity of Copper): The purity of the recycled copper is very important, especially if it is going to be used in high-quality projects. You should choose granulators that are known for making high-purity copper with few flaws or insulation remnants.

- Durability and Maintenance Requirements: For long-term use, durability is very important. Pick a granulator that is made with strong, high-quality materials. Also, think about how often the machine needs to be serviced. Granulators which are effortless to operate and maintain can decrease reduce delay and increase the machine’s effectiveness, ensuring that it works continuously and effectively.

You can choose a copper wire granulator that will not only match your current recycling needs but also be able to change to future needs. This will give you a safe and effective way to get copper back.

For the machine to stay efficient and last a long time, it needs to be serviced regularly and be easy to get to. When looking at these things, you should weigh the original investment against the money you might save in the long run by getting better results and cutting down on costs. A good high-efficiency granulator not only meets specific recycle needs, but it also makes the business more productive and profitable.

Technological Advancements

The efficiency and ease of use of copper wire granulators have been greatly improved by new technologies. Modern machines have more complex control systems that let them work more precisely and efficiently with less human help. This automation includes self-regulating features like auto-reverse mechanisms and real-time tracking that make the recycling process go more quickly. The automated settings and easy-to-use interfaces make it easier for workers to learn how to run the machines. This makes the whole process run more smoothly and efficiently and makes it easier for businesses to improve their recycling processes.

1: Pre-shredder

Usually, the pre-shredder has two types which are single shaft shredder and double shaft shredder, both have advantages and disadvantages:

the advantage of a single shaft is the copper wire can be crushed into smaller pieces more convenient for the following steps, but its output is relatively small.

The advantage of the double shaft is the output is relatively large, but the length of the crushed wire is longer than the former. It is also easy to jam the shredder when feeding too many wires at one time.

Luckily, our machine has already been updated to solve these problems. For a single shaft, We add a hydraulic rod that can press accumulated wires, better improve the output and solve the small output problem.

For the BSGH Granulator machine, and extra large copper wire granulator machine we use the single shaft as the first preshredder, for the small copper granulators, middle copper granulators and big copper wire granulators, we use the double shaft shredder machine, we will assemble the suitable one to prevent jams.

2: Air separation system

The principle of the air separation system involves using a fan to blow air from the bottom while simultaneously shaking a vibrating table to separate copper/aluminum from plastic. However, the effectiveness of this process varies due to differences in machine quality available on the market. This discrepancy arises from significant variations in core technology among different manufacturers.

The BSGH Granulator adopting advanced technology can make every factor contribute to the separation effect, such as the angle of the wind, wind speed and so on. To create an excellent separation effect. We use mature technology and also have a professional team to work in this field continuing.

3: Automatic System

Automation system includes self-regulating features like real-time tracking that make the recycling process more smoothly. The automated settings and easy-to-use interfaces make it easier for workers to learn how to run the machines. This will make the whole process efficiently.

4: Magnetic Separation

Under magnetic field, the magnetic mineral received the magnetic attraction is adsorbed on the roller, while the non-magnetic mineral is repelled by repulsive force.

Depending on this rule, the BSGH Granulator used strong magnetic forces and has better adsorption capacity. The advantage of installing a magnetic separator is that even if sometimes the waste wire seller claims the copper wire has no iron, however it still has it, which causes difficulties in subsequent recycling and brings economic losses. Installing a magnetic separator can better circumvent this problem and ensure the purity of copper.

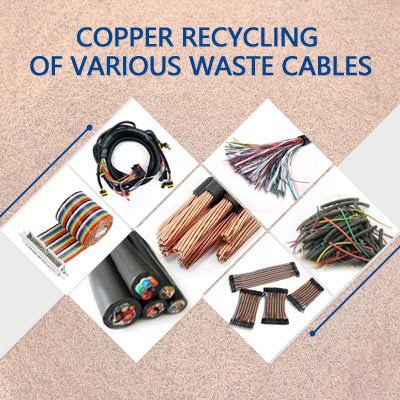

Cable Types and Diameter

It is necessary to clarify the type and diameter of waste cables when purchasing wire recycling machine that need to be processed and choose different machine configurations for different cables.

- Diameter: If the diameter of the cable is too small, the copper wire will easily attach to the pvc particles under electrostatic reaction, thereby reducing the copper recovery rate. At this time, it is necessary to use an electrostatic separator device at the plastic outlet to improve the recovery rate of copper.

- If your cable have iron, we suggest customer to install a magnetic separator above the copper outlet or on the conveyor belt in front of the main crusher.

- Think about how many scrap cables you need to process. For example, if a scrap yard is running through approximately 500 pounds per hour, a standard granulator might be sufficient. However, if the scrap yard is running through 2000 pounds per hour, a heavier duty granulator will be needed.

The Copper is Pure or Not

BSGH Granulator dry copper wire granulators machine is a waste wire recycling production line that processes various materials, including automobile wires, fine miscellaneous wires, aluminumplastic cables, and hair wires. Dual sorting process using airflow and vibration to achieve 99.9% high-purity separation, the final products can be sold directly. In this way, it can ensure maximum benefits of your recycling business

Cost Considerations

It’s important to think about the long-term benefits before you buy one:

- Initial Investment vs. Long-Term Benefits:A new model costs more, but it can be more profitable in the future due to better recycling ability, higher throughput, and efficiency. If you want to develop in this industry and have the vision to expand production, I suggest you purchase granulators with larger output if you have future plans and better quality. This will not only meet current production needs but also avoid repeated purchases of machines in the future. There are numerous benefits to implementing this approach:

- Even if in the near future you haven’t so much capacity, you can save much of your time and save more labor costs;

- If you have big processing capacity demands fast, thus you have enough big machine to process your scrap cables, no need to change your present machine, save a lot of cost.

- Operating Costs: Think about how much electricity is used and how muchthe maintenance fees it costs. Using granulator needs less energy and upkeep money which can cut down on ongoing costs in long run.

- Potential for Return on Investment: The return on investment is directly related to how well the granulator can make pure copper, and how much you buy the scrap material and material quality, Recyclingand handling that are done perfectly can lead to a higher return, which makes the initial investment more valuable.

Safety and Compliance

During operation, safety is the most important thing. BSGH copper wire granulator has many safety features to keep them from hurting, including emergency stop buttons, automatic shutdown systems, and protective shells. It is also very important to follow both local and foreign rules about the environment and safety. Most frequently, these rules are about noise, pollution, and how to handle trash. Providing workers with thorough training and clear instructions on how to use the about equipment also makes sure the safety lowing the probability of accidents.

Vendor Selection and Support

Choosing a well-known brand when buying a copper granulator machine is a wise decision. Good merchants can not only bring high-quality machines but also provide considerate after-sales service to ensure long-term use of the machines and great profits.

As the Powerful manufacturer and more than 25 years of production experience, we have many customer project case everywhere in China and all over the world: also have amount of good feedback from customer. BSGH Granulator copper wire recycling machine stands out in the market and 85% of the China market share, mainly rely on customer satisfaction, good quality, large output, high recycling rate and good performance of the equipment.

- First of all, we welcome buyers to come to the factory to inspect the machine at any time, because we believe the working performance of every BSGH granulator is stable even not test.

- Secondly, after the merchant purchases the granulator, our services do not stop there. We still provide considerate after-sales service to help buyers solve various problems encountered during the use.

- Finally, our machine can be used for at least 10 years. Merchants who have purchased them have given high feedback and bought related accessories from us years later. We have formed a stable cooperative relationship with customers from all over the world.

Chinese clients Advice

The following are some common traps of buying copper wire recycling machines, relevant suggestions:

Don’t be greedy when buying granulators, don’t consider that the appearance of cheap copper wire granulator machines looks similar to expensive machines, so they must be similar in working and buying the cheapest one. THEN YOU ARE WRONG, scrap copper granulation is different from other commodities, you can’t feel it if you don’t actually use, don’t care only granulator price.

You also need to find a really good manufacturer with amount of customer processing video, don’t only see the supplier video, many are fake video.

The copper wire granulation machine is a professional equipment for separate copper and plastic. If efficiency is too low, then at the same time you get less profits than others; or the separation rate is not good, then copper granules we produced will be difficult to sell, which is big loss for customer.

Tips for Maintenance

In order to extend the service life of the machine, you need to maintain the it regularly. This includes regular maintenance like cleaning, lubricating, and replacing old parts. You can set up a regular maintenance plan which can prevent the machine from breaking down without warning. The detailed recommendations are as follows:

- Applying grease on time can reduce the friction of the machine.

- You should obey the operating procedures and don’t overload the wires you put in.

- A regular inspection plan can help a lot which is good at preventing problems from happening.

Making the Decision

When making your final choice, think about everything we’ve talked about: cost, efficiency, capacity, safety features, vendor image, and maintenance needs. Look at your unique needs and how each choice fits with those needs. Making an educated choice will help you get the granulator that works best for you.

Conclusion

Selecting the correct copper wire granulator involves more than just processing wires. It’s about upping your recycling game, making wise, sustainable decisions, and getting the most out of your investment. Consider it more than just purchasing a machine, it is also about embracing a future in which efficiency and responsibility coexist. So, take your time, consider your options, and choose a granulator that is not only wonderful today, but also outstanding tomorrow. Here’s to making a decision that causes a significant impact, both in your operations and in the larger picture of resource utilization. Happy granulating!

You now have the knowledge and insight to choose the best high-efficiency copper wire granulator for your needs. The correct equipment is essential for boosting recycling efficiency, output quality, and profitability.

Hesitation can be expensive in the fast-paced world of recycling. Act now to transform your scrap cables into cash. Reach out to our experienced team today for specific advice or explore our comprehensive selection of top-quality copper wire granulators. Together, we can identify the perfect match for your specific requirements and budget.