Ⅰ. Introduction

The car is made of a variety of valuable materials. Steel, aluminum, rubber, plastic, etc. are all essential raw materials for making a car. Even after the car is scrapped, these materials still have a high recycling value. There are about 27 million cars scrapped every year around the world. If the valuable materials in these cars are not recycled, it will cause a huge waste of resources. Effectively recycling valuable materials from scrapped cars can not only promote the sustainable development of the world, but also bring ideal profits to individuals.

Can they be sold directly or do they need further processing?

So, what parts can be recycled from scrapped cars?

What machines are needed to recycle the parts in the car?

Ⅱ. Parts in scrapped cars that can be

dismantled and sold directly

You can choose to dismantle or sell directly for scrap cars. There are too many valuable parts in the scrap cars, according to the actual situation of scrapped cars, there are some parts in good condition that can be directly dismantled and sold. Next, we will briefly introduce to you these auto parts that can be sold directly.

1. Spare Tire

A spare tire is an accessory that most cars are equipped with. But in fact, only a small number of cars have their spare tires replaced during use. Therefore, when they are scrapped, many cars still have brand new spare tires. If the spare tires have not been used, they can be sold to auto repair shops for secondary use.

2. Car Battery

Under normal circumstances, the service life of a car battery is about 3 to 5 years. If it is well maintained, it can be used for longer. You can dismantle the car batteries in good condition and sell them to battery recycling merchants to make a profit.

3. Air Conditioner Compressor

The air conditioner compressor is the core part of the car air conditioner and can usually be used for more than ten years. If the air conditioner compressor of a scrapped car is still in good condition, you can remove it and sell it.

4. Catalytic Converter

The catalytic converter is a purification device that can convert automobile exhaust into harmless gas. Because it contains precious metals such as platinum, rhodium, and palladium, the catalytic converter has a great high recycling value. Therefore, even if you directly sell the catalytic converter, you can still make a good profit. In addition to selling it directly, you can also use professional equipment to recycle the precious metals in the catalytic converter, which can achieve higher economic benefits and maximize your profits.

5. Electronic Digital Devices

The electronic digital devices of a car mainly include a driving recorder, camera, navigator, reversing image screen, etc. These devices could be normally secondary used as long as they are not damaged.

6. Car Windshield

Auto windshiled is made of glass and bonding interlayer, PVB film inside has a great recycling value, widely used in daily life, construction and industrial use.

IN ADDITION to the parts mentioned above, oil pumps, water tanks, airbags, and other parts can also be sold directly. You can make considerable profits by selling these parts.

Ⅲ. What Machines Can You Use

To Recycle Scrap Cars

You can find various machines for processing auto parts at BSGH Granulator. These machines are specially designed for different auto parts and can meet your various needs for recycling scrapped cars. We will introduce these machines to you so that you can quickly understand how to recycle scrapped cars.

⭐ Crushing and Packaging of Automobile Shells

Car shells are generally made of steel, aluminum, reinforced plastic and other materials. If you want to crush car shells quickly, you can try to use a heavy-duty double-shaft shredder and car shell hammer crusher.

The heavy-duty double shaft shredder crushes car shells into small pieces by continuously shearing, tearing, and squeezing them during the processing. It is an ideal machine to help you save space and reduce transportation costs.

In addition to crushing car shells, the car shell hammer crusher can also effectively separate metal materials such as iron and aluminum and non-metal materials. If you need the separation function, the car shell hammer crusher is the most suitable machine for you. When the machine is operating, the hammer head will first strongly impact the car shell to crush it into small particles. When these particles are conveyed out of the crusher, the magnetic separator will suck out the iron from them. Finally, the eddy current separator will separate the processed materials into metal substances and non-metal materials.

The hydraulic car baler is the best choice for packing car shells. It can effectively compress the car shell into rectangular blocks, and its equipped grab bucket can help you achieve fast feeding, greatly improving production efficiency.

⭐ Recycling of Car Engines

We have equipment specially designed for crushing car engines, which can crush them into small pieces of 3~5cm. Its advanced crushing technology and strong power support the rapid crushing of various car engines.

⭐ Crushing and Separation of Automotive Cables

The copper wire granulator is the best equipment for processing automotive cables. It is not only suitable for automotive cables, but also for processing household cables, telephone cables, network cables, and other waste cables with a diameter of less than 30mm. It can crush waste cables into 3~5mm particles, and then use physical methods to separate copper particles from plastic particles. The copper wire granulator can efficiently recycle 99.9% of the copper in waste cables, and finally, you will get copper with purity as high as 100%.

⭐Recycling of Automobile Alternators

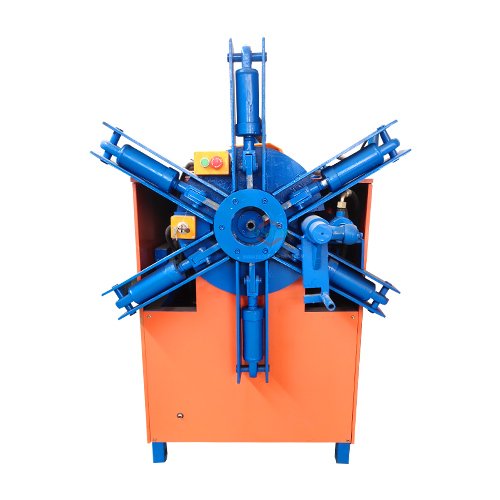

We mainly have three types of machines for recycling car alternators, car alternator cutting machine, car alternator pulling machine, and car alternator cutting and pulling machine. You can use the car alternator cutting machine to cut one end of the copper winding in the car alternator stator, and use the car alternator pulling machine to pull out the entire copper winding in the stator. The car alternator cutting and pulling machine is a multifunctional machine that combines the cutting function and the pulling function in one.

⭐ Recycling of Automobile Starters

Car starters also have copper windings with high recycling value. But compared to car alternators, car starters are more difficult to recycle. We have four main machines that can help you recycle the copper windings in car starters, and you can combine them to recycle car starters.

- First, you can use the Auto Starter Rotor Cutting Machine to cut one end of the copper windings from the car starter rotor.

- In the second step, using Hydraulic Scrap Metal Wrecker Machine can help you press the copper windings in the rotor, making them easier to recycle.

- The third step is to heat the car starter with the Car Starter Heating Machine. Please do not underestimate the importance of this step, it can prevent the copper windings from sticking to the car starter.

- Finally, you can effectively recycle all of the copper windings in your car starter using the Auto Starter Motor Pulling Machine.

⭐Recycling of Automotive Magnetic Switches

The car magnetic switch is a part of the car starter. It has a high copper content, so the profit you can get from recycling the magnetic switch is relatively high. The magnetic switch recycling machine can help you quickly recycle the copper winding in the magnetic switch. It first pulls the stator out of the magnetic switch and then separates the copper winding. The whole process only takes about 10s to complete.

⭐Recycling of New Energy Automobile Motors

With the development trend of the automobile industry, the number of new energy vehicles is growing at an increasingly rapid rate. In this context, the recycling of new energy vehicles is bound to become a difficult problem in the future. As a manufacturer with the most advanced technology in the scrap metal recycling industry, BSGH Granulator took the lead in researching and manufacturing equipment that can recycle new energy car motors.

Since the new energy motor stator recycling machine has stronger power and greater torque, it can efficiently recycle new energy motor stators that most machines on the market cannot recycle. The new energy motor stator recycling machine also has a cutting part and two pulling part. After cutting the copper windings with the cutting part, put the motor stator into the pulling part of the machine, and the jaws will automatically pull out the entire copper windings.

The rotors of new energy motors contain high-value strong magnets, and recycling these strong magnets can also enable you to obtain ideal profits. Recycling the rotors of new energy motors only requires two steps.

- First, use a motor shaft-pulling machine to remove the shaft from the rotor. You only need to fix one end of the motor rotor on the motor shaft pulling machine and start the machine, and the machine will automatically complete the shaft-removing process.

- The second step is to use a heating machine to heat the motor rotor without the shaft. After the heating finish, you can manually recycle the strong magnets in the motor rotor.

⭐ Recycling of Catalytic Converter

As mentioned above, in addition to selling the catalytic converter directly, you can also get higher economic benefits by recycling the catalytic converter. The recycling of the catalytic converter mainly involves recycling the honeycomb materials containing precious metals such as platinum, rhodium, and palladium. Our catalytic converter recycling machine can help you achieve this goal. Its sharp knife can easily break the hard shell of the catalytic converter. After this process, you only need to manually peel off the honeycomb materials.

⭐ Recycling of Windshield

Most scrap yards simply discard scrap car windshields or sell them directly because manual process is greatly dangerous. However, professional auto recyclers will recover the valuable internal PVB film. With BSGH Granulator Windshield PVB Film Separation Line, you can effortlessly turn windshied into profits, just feed waste directly into our separator line and you will get clean PVB flakes, if want whole piece of PVB film, use our specialized roller press to pre-process first then crush and separate to get higher price PVB. For more details, just contact us freely.

Ⅳ. Conclusion

IN SUMMARY, you can make money from all the parts of scrap cars. In addition to parts that can be sold directly, the processing range of our recycling machines covers almost all parts of scrap cars. Using these recycling machines can help you improve productivity, simplify operation processes, and save labor costs. Choose to cooperate with us, BSGH Granulator is willing to create a future that achieves sustainable development and ideal economic benefits together with you.