Introduction

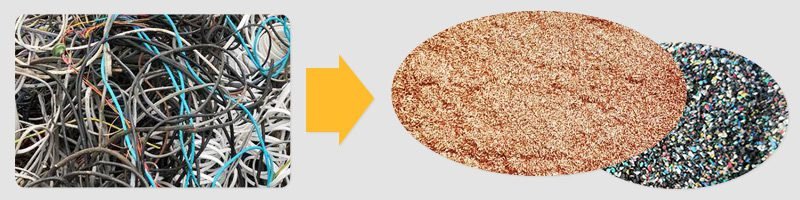

The Copper Granulator Machine stands out as an innovative tool affecting how human recycle important metal from waste wires and equipments. This machine is more than a piece of equipment, it is a key in transforming waste into a valuable resource. Copper Granulator Machine from BSGH Granulator not only plays a part in changing traditional recycling methods but also makes an effort to find more solutions. Recycling copper instead of discarding them is better for the environment and safer for human health. Come with us and learn what this amazing machine can do and why how it is so popular in the national market.

Understanding Copper Wire Recycling

Starting a copper wire recycling firm opens the door to a world where profit and environmental responsibility coexist. Copper can be found inside scrap cables and waste technological equipments, so recycling it can reduce metal pollution on land and effectively supplement the scarcity of metals also brings benefits which is meaningful in material and environmental fields.

Copper is a valuable metal that many people prefer. Copper is a valuable metal that many people prefer. Copper is widely used in communication wires as a conductor to transmit electricity due to good conductivity. Copper is also extensively applied in various vehicles in which the wires, motor, batteries, etc because its corrosion resistance ensures durability and prolongs the service lives. The use of copper can be seen in our daily lives, so the potential is huge and immeasurable.

Preserving Natural Resources:

Reusing recycled copper takes us one step further to alleviate the shortage of copper resources and resolve the contradiction between environmental protection and resource utilization.

Environmental Impact- A Greener Footprint: Reusing copper wire reduces greenhouse gas emissions considerably when compared to extracting and refining fresh copper. Making this environmentally beneficial decision is a proactive move against climate change.

Energy Savings:Compared with primary copper production, each ton of recycled copper saves about 1 ton of standard coal and nearly 400m3 of water, also reduces solid waste emissions by 380 tons, which is equivalent to reducing the emission of sulfur dioxide by 0.137 tons and saving 87% of energy. Making fresh copper from ore requires far less energy than recycling copper wire. This efficiency lowers total industrial energy consumption in addition to conserving energy.

Minimizing Waste: Recycling copper wire is becoming more and more important as the amount of electronic waste made around the world rises. A lot of trash stays out of dumps, which helps keep the Earth clean and healthy. How to Do It: Getting old copper wire is the first thing that needs to be done. Then it is carefully put in order by quality. The wire is then recycled well to get rid of any insulation or dirt.

The Copper Granulator Machine’s Function: Technology really shines here. The Copper Granulator Machine effectively separates copper from its insulating substance by converting the wire into granules. This procedure guarantees the quality of the copper while also streamlining the recycling process.

What exactly is a Copper Granulator Machine?

In the specialized field of metal recycling, the Copper Granulator Machine looks like an important tool for handling used copper wire. This machine is more than just a piece of equipment; it’s an advanced system made to turn copper wire into a useful recovered material. Here are some of the things about this machine that make it such an important tool in the recycling industry.

Detailed Functionality of the Copper Granulator Machine

Designed for Copper Wire Recycling: The Copper Granulator Machine’s principal function is to treat discarded copper wire. It handles wire efficiently, turning it into small, manageable granules.

Operation Mechanism: The machine works by performing a series of mechanical motions. It first shreds the copper wire into smaller pieces. These fragments are then further broken down into granules, a more recyclable form.

Ensuring Output Purity: The ability of the Copper Granulator Machine to create clean copper granules is an important feature. The machine effectively eliminates any insulation or contaminants adhered to the copper wire throughout its processing.

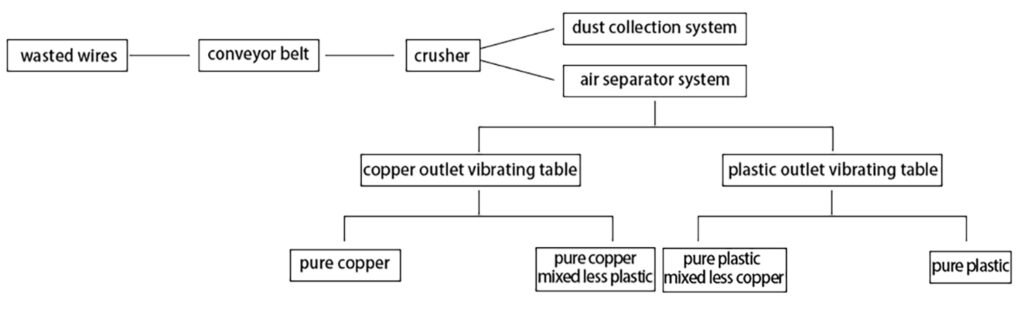

Cable Processing Flowchart:

Core Features of the Copper Granulator Machine

Dual Processing: Shredding and Granulating:

- The machine is outfitted with efficient cutters that shred the copper wire at first. The granulating component then takes over, refining the shredded wire into granules.

- Efficient Separation Technology: The machine uses modern technology to extract copper grains from insulating materials. This separation is critical to ensuring the recycled copper’s purity.

- Operational Security and Efficiency: The Copper Granulator Machine was designed with safety in mind. It has several features to ensure safe functioning:

- Emergency Stop: Safeguards the entire machine in urgent conditions.

- Whole Machine Protector: Automatically stop operation in the event of leakage, short circuit, or overheating.

- Motor Protector: Prevents motor burnout by responding to overloads.

- Contactor: Shields each motor in case of individual motor overload. These safety features not only enhance the security of the machine but also contribute to its overall operational efficiency.

4. Furthermore, the machine is energy-efficient, optimizing output while decreasing energy usage.

5. Working with a Variety of Copper Wire Types: – Another feature that distinguishes this equipment is its versatility. It can process a range of copper wire kinds, making it an invaluable machine for various recycling purposes.

The Copper Granulator Machine is a highly specialized equipment in the recycling sector that is designed to treat scrap copper wire efficiently. The capability to produce high-quality, completely pure copper granules makes it an important piece of equipment for any person in the copper wire recycling business. The Copper Granulator Machine stands out for its precision, efficiency, and versatility as we continue exploring effective recycling solutions.

Step-by-Step Guide to Using a Copper Granulator Machine

Learning the Copper Granulator Machine is important for customers to operate it well and earn big profits. Here’s a step-by-step guide to getting the most out of this energy-efficient equipment.

Getting Ready

- Gather and Sort Your Copper Wire: Starting with, collect as much scrap copper wire as you can find. Look for discarded electrical cords, appliance wires, and other technological devices.

- Sort the wire according to its type and quality. This step is critical since various wires may necessitate different machine settings.

- Setup of the Machine: Make sure your Copper Granulator Machine is clean and in good operating order before you begin. Check its blades, crusher sieve, and other components.

- Set the machine according to the manufacturer’s instructions. Apply any necessary changes for the specific kind of wire that you’re working with.

Machine Operation

- Wire Feeding: Carefully feed the sorted wire into the machine. It’s critical to move at a constant speed to avoid overloading the machine, which can lead to clogs.

- Monitor the machine as it works to ensure that everything is working smoothly.

- The Granulation Process: The machine will shred the copper wire into mixed copper and plastic pieces, then copper will be separated from plastic insulation.

- As a result, the copper granules are small and consistent, making them easier to sell and recycle.

After the Granulation

- Collecting the Copper Granules: Gather the copper granules after the wire has been treated. These should be clean and free of debris and insulation.

Keep the copper rice in a clean, dry, and free of dust place which can maintain a good quality until they are sold.

Remember to handle other granulates: Other granulates should be processed according to the local legislation.

Maintaining Your Machine

- Regular Cleansing and Maintenance:

- Regular maintenance is needed to maintain your Copper Granulator Machine in good working order. Clear it regularly and inspect it for any parts should be replaced.

- Maintenance of your machine following the manufacturer’s instructions.

- Troubleshooting: Be prepared to deal with frequent issues such as wire jams or inconsistent granule sizes. Knowing how to rapidly resolve these issues will keep your business functioning successfully.

- For more complex concerns, check the machine’s handbook or consult a specialist.

By following these instructions, you will be able to properly recycle copper wire with your Copper Granulator Machine. This not only helps to reduce waste but also converts scrap into a valuable resource.

Remember that the secret to efficient copper wire recycling is using the machine in the right way and working out regular maintenance to protect it too.

Increasing Productivity and Profitability with a Copper Granulator Machine

It is necessary to make full use of your Copper Granulator Machine to turn copper wire recycling into a profitable and efficient business. Here are a few helpful tips to maximize your recycling operation.

Optimizing Your Operations(Very important)

- Input Quality Is Important: Begin with high-quality scrap wire. Purer copper granules are more valuable in the scrap market when the wire is cleaner and less oxidized. Sorting your wire into comparable types before processing helps improve machine efficiency and output consistency.

*Like square wire, in order to let machine reach its best ability, you can use bigger crusher sieve and bigger small table separator sieve, this will improve efficiency greatly.

*Like thin wire or mixed wire, you can use smaller crusher sieve and smaller table vibrator sieve and adjust the bottom fan or vibration frequency to get the most pure copper.

Also according our experience more than 25 years and our customer feedback, when you process different kinds of cables sorting them first and then processing them separately will improve your efficiency fast, during the handling, you can process thin cables first, then thicker cables. In this way, the adjustment is little saving more time also making the machine reach the best condition.

Depending on these valuable experiences, we always help our customers stimulate the optimal working state of the machine.

- Maintain Consistent Feeding: Ensure a consistent and controlled supply of wire into the granulator. Overloading the machine can cause clogs and malfunctions, but underfeeding decreases its efficiency.

- Regular feed rate monitoring and adjustment are required to keep the machine running smoothly.

Enhancing Product Quality

- Optimize Settings for Maximum Output:

- Adjust the machine’s parameters to suit the sort of wire you’re working with. This could include changing the granule size or the processing speed.

- Experiment with these settings to determine the ideal configuration of the machine, to produce high-quality homogeneous granules.

- Maintain Copper Granule Quality: Inspect copper granules on a regular basis. Granules with 100% purity and consistency are more marketable and attract higher pricing.

- Consider adjusting the machine settings or the pre-processing stages if the granules are uneven or contain contaminants.

Economic Policies

- Stay Informed About Market Trends:

- Stay updated on copper market pricing. Selling your copper at the peak of the market can greatly increase your income.

- Develop ties with a range of buyers to guarantee you have stable customer sources to ensure long-term profits.

2. Consider the Advantages of Bulk Sales:

- Accumulating a bigger quantity of copper granules before selling might be more profitable, as bulk amounts frequently command higher prices.

- Balance this method with your storage capacity and short-term cash flow needs.

Upkeep and Training

- Make Regular Maintenance a Priority:

- Perform routine maintenance checks and service to prevent machine breakdowns and extend its lifespan.

- Replace any worn parts as soon as possible and keep the machine clean to guarantee peak efficiency.

- Skilled Operation Is Important:

- If you have a team, make sure everyone is well-versed on how to use the Copper Granulator Machine. Efficient operation by skilled workers can considerably improve output quality and overall productivity.

These ideas can help you run a more effective and booming copper wire recycling business. Understanding your machinery, staying market-savvy, and maintaining good operational standards are the keys to success.

Conclusion

Recycling with the Copper Granulator Machine is wise for the environment and the economy. This machine streamlines copper wire recycling, making it lucrative. It meets market expectations and decreases environmental impact by producing high-quality copper granules. Maximizing its potential requires regular maintenance and competent operation. As we seek sustainable solutions, including such modern technologies into recycling procedures shows a dedication to saving resources while maximizing their worth. The Copper Granulator Machine is essential to modern recycling.

Beginning your recycling business with BSGH granulator and collecting waste wires and equipments leads a boost in money and protection in environment. Act now! We are ready to work with you at any time.

Tags: #coppergranulator #recycling #scrapcables #metal #scrapyard #metalscrap #copperrecycle