I. Introduction

Cable is a high-value copper scrap material, proper recycling can bring you/recyclers considerable profits. However, the scrap copper wire in the world is diverse, with numerous types varying in diameter, insulation thickness and structures. Different types of scrap copper wire require different recycling methods; using the wrong methods can lead to significant copper loss, damage to the recycling equipment and frustratingly lower operational efficiency.

This guide will delve into the best solutions for recycling various copper wire scrap, helping you maximize your returns and streamline your operations.

II. How to recycle common types of copper wires?

When processing common type wires, including square wires, communication wires, household cables, power wires, network cables, computer case wires, telephone lines, data cables, various electronic equipment wires, etc., two types of machines are most commonly used: wire stripping machines and cable granulators (or copper wire recycling systems).

Wire Stripping Machines: These machines utilize blades to precisely cut and remove the insulation from the copper conductor. They are generally most suitable for thicker, single-core wires, typically those with a diameter exceeding 25mm. The output is clean, stripped, bright and entire copper wire and separated insulation, you can sell a higher price.

Cable Granulators: These systems take a different approach. They first chop the wires into 3-5mm granules of copper-plastic mixture. Then, through a combination of physical separating technologies (often involving air separation and vibration tables), they separate the heavier copper granules from the lighter plastic insulation granules. Cable granulators are more functional when processing thin wires (typically less than 25mm in diameter) that wire stripping machines cannot efficiently handle. They are also excellent for mixed wire batches and more complex cable constructions.

But what happens when you encounter more complex or challenging cable types, such as automotive wires, armored cables, or metal-clad cables? Let’s explore tailored solutions.

III. Recycling Solutions for 7 Special Types of Scrap Copper Wire

Understanding the unique characteristics of each wire type is crucial for selecting the optimal recycling machinery. Here are seven common distinct types of scrap copper wire and their suitable recycling solutions:

1. Automotive Wires

Challenge: Automotive wiring harnesses are complex, typically wrapped in different types of tape, plastic sheathing, or fabric loom coverings. This tape can become sticky and problematic for standard stripping methods.

Solution: Due to the tapes and mixed nature, automotive wires must be recycled using a copper wire granulator. The following machines can effectively break down the entire harness and separate the copper from the diverse non-metallic components, they have different capacity and different configurations, you can choose proper one according to your demands.

Example Machines:

BS-D75 copper granulator machine

BS-D75 is the smallest three-phase copper granulator machine of BSGH Granulator, which can process about 70 kg of scrap wires per hour. Although small, but our BS-D75 copper granulator machine has a good recycling effect on automotive cables, it is the best choice for recyclers with a small amount of scrap wires. If you don’t have three-phase electricity, we also support customizing the single-phase electricity version for you.

BS-N130 Cable Shredder

The Middle BS-N130 cable shredder machine has a bigger processing capacity of 400-700kg/h. It is equipped with a pre-shredder, which can shred the automotive wires into 5-25cm long strips before entering the main crusher, effectively protecting the main crusher blades.

BS-F3000 copper cable granulator

BS-F3000 copper cable granulator is our biggest standard model, with a processing capacity of 1200-1500kg/h. It has the most complete configuration, so choosing it means you won’t need to invest in additional auxiliary equipment. If you have many scrap cables(including car wires, mixed cables) or some other scrap radiators, fuses, BS-F3000 copper cable granulator is worth investing in.

2. Armoured Cables

Challenge: Armored cables are built tough and for special use. They have a protective metal armor layer beneath an outer sheath, designed to withstand harsh conditions. The copper conductors within are generally thick.

Solution: These cables are generally thicker and possess a hard armor layer on the surface. Therefore, they are more suitable for processing with a heavy-duty wire stripping machine, which can cut through the hard metal armor layer of armored cables and easily recover the inner copper wire; if you want to process amoured cable in one time, you can consult us to get more detailed information.

Example Machines:

BS-AC80 wire peeling machine

BS-AC80 wire stripping machine has 12 round holes, 1 pressing hole, and 2 frame holes, allowing it to strip scrap wires ranging from 2 to 76mm; it is the smallest stripper model capable of strip armored cables. Designed for ease of use, BS-AC80 requires minimal adjustments during operation. Additionally, it is equipped with universal wheels for easy mobility, making it highly convenient for various work environments.

BS-AN130 automatic cable stripping machine

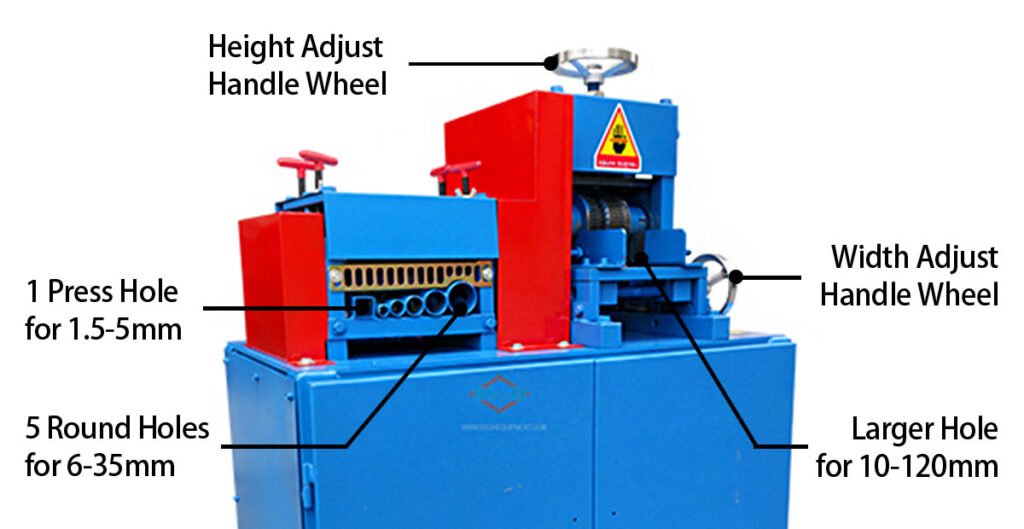

Our heavy-duty BS-AN130 automatic cable stripping machine is ideal for processing armored cables. It can handle a wide range of cable types with diameters from 1.5 mm to 120 mm, including armored, high-voltage, and high-density cable types that ordinary wire stripping machines often cannot process. With dual-sided operation, both the left and right sides can work simultaneously, significantly increasing stripping efficiency and overall productivity.

3. Single-Strand Multi-Core Cable

Challenge: This type of cable is usually wrapped in a thicker outer insulation layer, with multiple independent insulated wires inside. It is usually difficult to recycle in one step, and using only a wire stripping machine is inefficient.

Solution: A two-step approach is often best. First, use a wire stripping machine to remove the outermost insulation layer. Then, feed the multiple copper wires into the copper wire granulator for efficient crushing and separation.

Example Machines:

BS-AN125 heavy-duty stripping machine(for stripping the outer jacket) + BS-D10 copper wire shredder machine (a smaller granulator for the inner cores)

BS-AN125 heavy-duty stripping machine

BS-AN125 heavy-duty stripping machine has a wide stripping range, it can handle waste cables with diameters ranging from 1.5mm-120mm, so even thicker single-strand multi-core wires can be well processed. You can use it to completely strip the outermost insulation layer of single-strand multi-core wires for the next recycling step.

BS-D10 copper wire shredder machine

BS-D10 is one of our best-selling small copper wire shredder machines, which can process about 100kg of scrap wire per hour. It combines the most advanced air separation technology and vibration separation technology to maximize the extraction of copper from the wire and maximize your profits.

4. Slim Wires (Diameter < 2mm)

Challenge: Extremely thin wires, sometimes called “hair wires” or found in fine electronics, are impossible to strip effectively. During granulation, very fine copper particles can be lost with the plastic particles or fail to separate cleanly.

Solution: A cable granulator is the primary processing choice for you. To maximize the recovery of these thin copper particles, it’s highly recommended to add an electrostatic separator as an auxiliary device. This specialized equipment uses electrostatic charges to separate the fine conductive copper particles from non-conductive plastic granules.

Example Machines:

BS-D20 wire chopper machine + Electrostatic Separator

The small BS-D20 wire chopper machine has a processing capacity of about 200kg/h. When processing fine wires with a diameter of less than 1mm or 2mm, we strongly recommend that you add an auxiliary device electrostatic separator. It can separate the final product again after output, extracting the extremely fine copper wires that the air separator cannot separate from the plastic particles, greatly improving the recovery rate.

5. Rubber Cable

Challenge: Rubber insulation can be soft, pliable, and sometimes sticky, making it difficult for standard stripping blades to get a clean cut without stretching or slipping.

Solution: Because rubber wire is soft, it needs to be processed by cable granulators or wire stripping machines equipped with frame blades. Frame blades offer better support and ensure a more consistent and effective cut on these softer materials.

Example Machine:

BS-AC55 copper cable stripping machine

The BS-AC55 copper cable stripping machine is equipped with 19 feed ports and has a processing range of 2-50mm. This machine has 16 frame blades, range diameter of 4-36mm, which can efficiently and easily strip soft wires such as rubber wires, shielded wire.

6. Metal-Clad (MC) Cable

Challenge: MC cables have an interlocked metal armor (typically aluminum or steel) that is directly wrapped around the insulated conductors. This construction is distinct from the heavy, isolated layer found in “Armored Cables.”

Solution: Metal-clad cables are so special that specialized equipment is often required. For instance, BSGH Granulator has designed a stripping machine specifically for recycling them, capable of handling the unique interlocked armor.

Example Machine: BS-30A BX wire stripping machine + BS-KOF cable peeling machine

BS-30A BX wire stripping machine

The first step in recycling metal-clad cable is to strip its interlocked metal armor. BS-30A BX wire stripping machine is our recycling equipment specially designed for BX wires and MC wires. It has four feeding ports and is suitable for metal-clad cable with a diameter of less than 30mm. The stripped aluminum or steel armor layer can also be well recycled.

BS-KOF cable peeling machine

After being processed by BX wire stripping machine, you will get ordinary cables with plastic insulation, which can be processed by common wire stripping machines. We recommend our BS-KOF cable peeling machine, one of our best-selling models. It can process cables with diameters between 1.5mm and 50mm, with mature technology and high cost performance.

7. Miscellaneous Wires

Challenge: This category includes a jumble of various household wires, data cables, low-voltage wires, and other mixed small-gauge cables. Sorting and attempting to strip each individually would be incredibly time-consuming and inefficient.

Solution: For a diverse mix of miscellaneous wires, a copper wire granulator is highly recommended. It can process the varied assortment simultaneously, separating copper from different insulation types and greatly improving overall recycling efficiency.

Example Machine:

BS-D30 wire grinding machine

The processing capacity of BS-D30 wire grinding machine reaches 300kg/h. It is very popular in the United States, South America, Malaysia, and other places. Our machine can extract 99.9% of copper from various types of cables, while greatly improving your recycling efficiency, and is very suitable for processing miscellaneous wires.

III. Conclusion

The key to successful and profitable copper wire recycling lies in understanding the nature of your scrap material types and selecting the appropriate processing technology. As mentioned above, wire strippers and cable granulators are suitable for different types of cables, and special wires often require customized solutions or even dedicated equipment.

By correctly matching the recycling method to the specific type of copper wire scrap, you can:

1. Maximize copper yield and purity.

2. Minimize copper loss.

3. Prevent unnecessary damage to your equipment.

4. Achieve higher processing speeds and overall efficiency.

Investing in the right machinery, such as investing in BSGH Granulator models mentioned for specific tasks will ultimately lead to a more profitable, efficient, and sustainable copper recycling operation. When you have any doubts, you can consult us at any time and our experienced staff can provide valuable guidance tailored to your specific needs.