In various applications, copper wires are commonly used as conductors. There have many different types of copper wires, including Flat Copper Wire, Oxygen-free Copper Wire, twin-core flat cable, communication wire, etc.

These wires typically consist of copper and plastic, while certain specialized cables might also incorporate iron, aluminum, and other metals. With the growing awareness of copper recycling and reusing, the methods for effectively recycling these discarded wires is very popular, but many people have doubts:

How do you recycling copper wires?

8 Ways to help Recycling Copper Wires

Many newcomers to the industry are skeptical that recycling scrap cables is not profitable. This is because they have yet to find the right strategy, resulting in a lack of profit or even losses.

How to remove insulation from copper wire for recycling? This article will thoroughly analyze all aspects of cable recycling methods.

So, what's the most effective way to recycling copper wire?

The most effective method for recycling old cables is to use a copper wire granulator or automatic copper wire stripping machine instead of selling them to a scrap metal recycling company. These two methods are currently the most popular and practical options in the market. If you still not know how to? Contact your BSGH expert.

For individual or plant with small quatity of scrap cables

Many individuals or small-scale recycling plants occasionally gather small amounts of scrap cables with the intention of turning into profit. For these entities, the following methods can be a favorable choice.

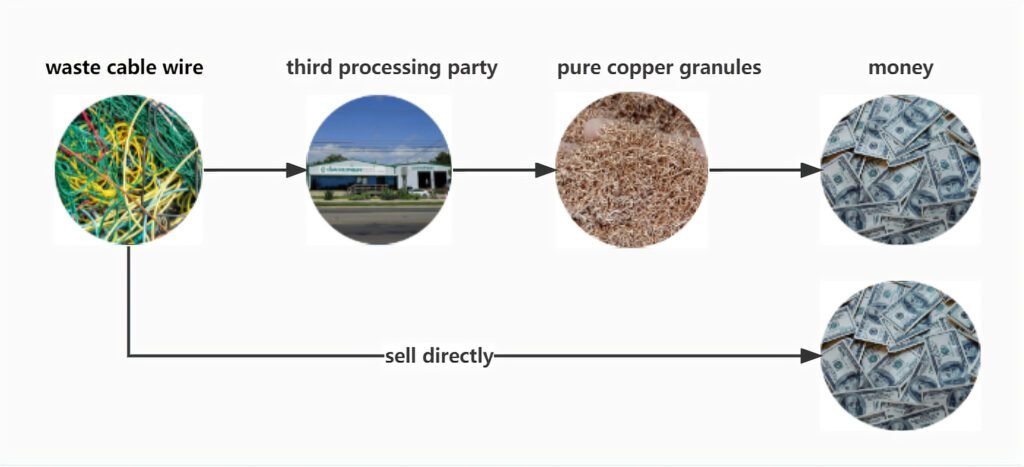

1: Sell Directly

Recycling waste cables by yourself might seem troublesome,then you can actually find buyers on platforms like Facebook, Instagram, Google, and other similar software to sell them directly.

2: To Third Party Processing

If you have spare copper cables that you’d like to recycle but don’t want to invest in copper wire recycling machine, you have the option to send them to a recycling plant. These plants offer a service where they process the cables for you, typically charging a fee. In return, you can obtain pure copper and can sell directly.

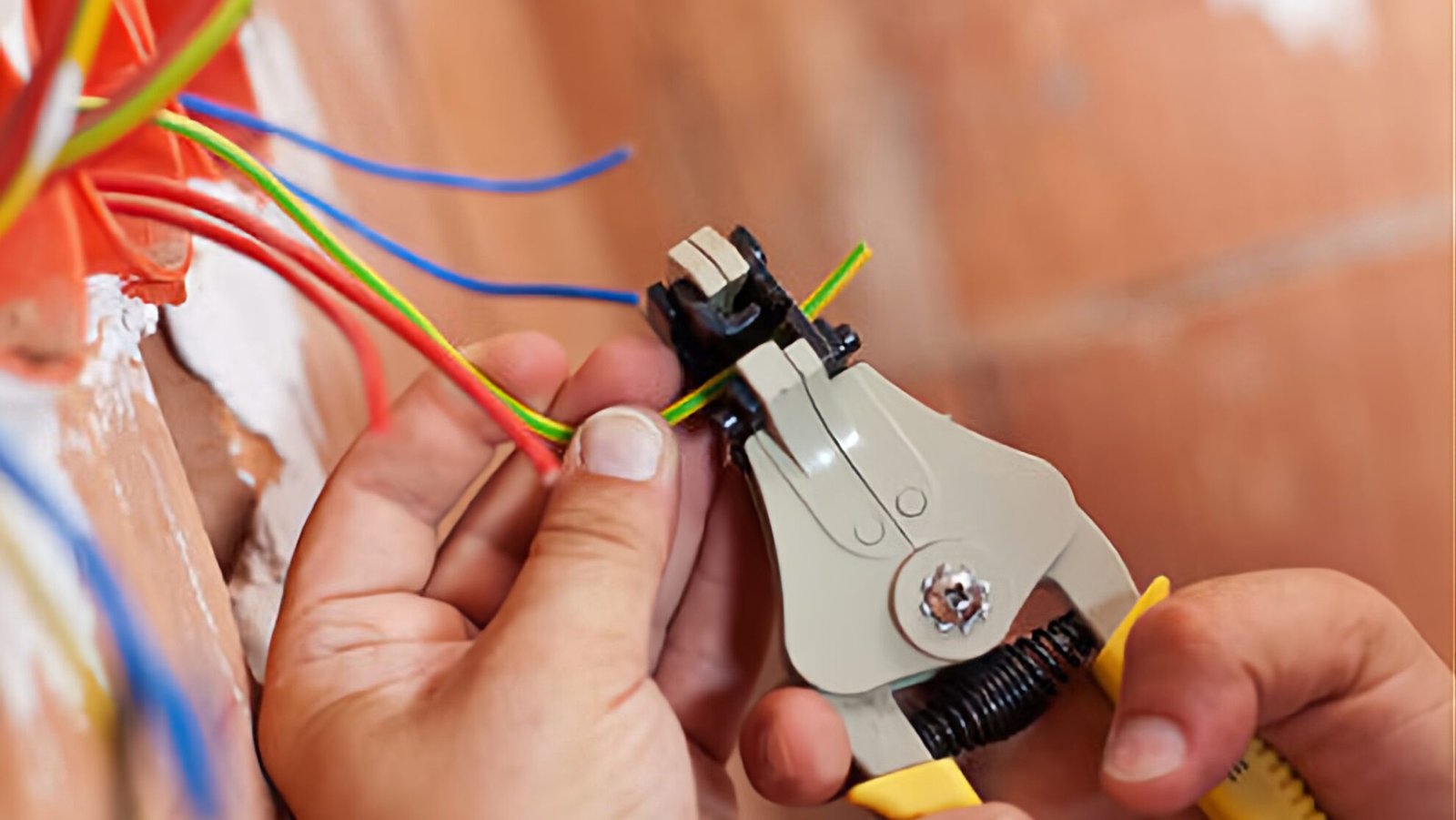

3: Man-Made Dismantling

Manually dismantling involves workers using handheld tools to remove the plastic from cables and extract pure copper. This approach prevents copper oxidation and environmental pollution. However, it’s highly inefficient and practical only for a small quantity of cables. Additionally, the cable diameter must be sufficiently large, as processing overly small cables can be challenging and might lead to copper loss.

4: Manual Stripping Machine

The manual wire stripper is a basic tool for removing insulation from wires. It’s operated by hand and is compact, easy to use and cost-effective. This type of stripper is suitable for small-scale cable recycling and processing plants, as well as individuals who need to remove insulation from wires. However, due to simple design and reliance on manual labor, it has limited efficiency, suited for small production runs.

Traditional Methods

Here are two traditional methods that have a long history and ever populat in the past. However, due to changing times and increasing environmental awareness, these methods have proven to pollute the environment, leading to prohibition in many countries.

5:Fire Scrap Copper Wire

This method is the traditional separation and recovery method of “burning copper by fire”, which uses the combustible nature of the cable sheath to burn the waste wires and cables, and then recovers the copper inside. This method seems to save the cost of the copper wire recycling machine, but in fact there are many disadvantages, In the process of wire incineration, the surface of the copper wire is severely oxidized, which reduces the copper value, and the burning of the wire sheath has a greater pollution to the environment. Besides, this method is limited to processing only relatively thick copper wires. Under the current environmental protection policy this method is explicitly forbidden.

6: Water Recycling

Although the water recycling method works well for crushing and separating, but with constant water input causing extra pollution, moreover copper easily speed up oxidation and reduce copper purity.

Most Effective & Widely Used Ways

In today’s world, people are increasingly aware of the importance of reusing resources and prioritizing environmental protection. As a result, the use of efficient automatic machinery methods has gained significant notice worldwide. And the machine is an excellent solution for efficiently recycling large quantities of cables. Following 2 method is main recycling way now.

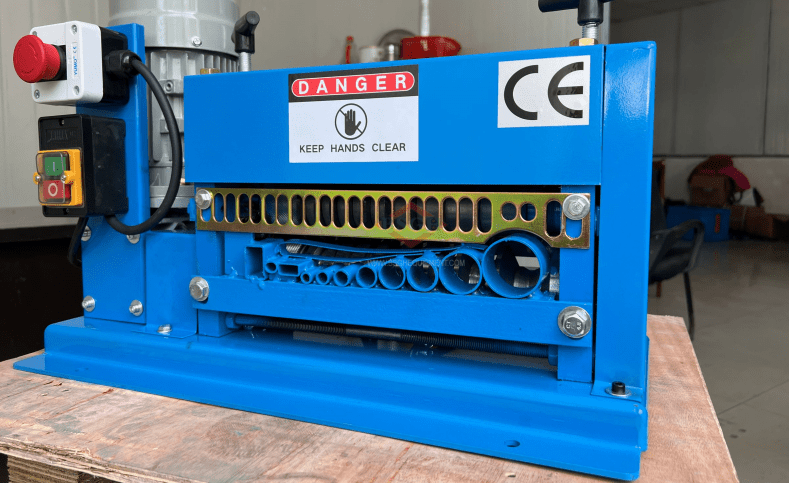

7: Automatic Copper Wire Stripping Machine

An automatic copper wire stripping machine is designed to remove the plastic coating and metalcore from wires automatically. It enhances efficiency, reduces labor, and minimizes copper waste compared to manual stripping. Automatic copper wire stripping machine are also widely used all over the world, however, it’s suited for customers with modest processing needs. For efficiently recycling big amounts of waste copper cables, a dry copper wire granulator is the preferred solution.

BSGH is a reputable cable recycling manufacturer with over 20 years of experience in the industry. We offer a range of high-quality machines to cater to your specific needs. Below are some of our most popular machines that are currently in high demand. Feel free to select the one that best suits your requirements:

|

Model |

Range |

Size |

Weight |

|

2-48MM |

710*595*987MM |

134KG |

|

|

2-72MM |

775*640*1030MM |

175KG |

|

|

10-120MM |

710*510*1130MM |

205KG |

|

|

15-120MM |

600*500*1250MM |

185KG |

|

|

BS-4 |

2-80MM |

850*440*570MM |

121KG |

|

BS-KOF |

2-55MM |

760*640*920MM |

115KG |

|

BS-KOB |

2-45MM |

750*670*970MM |

115KG |

|

BS-009 |

2-40MM |

620*440*65MM |

72KG |

Note: Machine voltage 110V/120V/220V/380V; 50HZ/60HZ, also support customized.

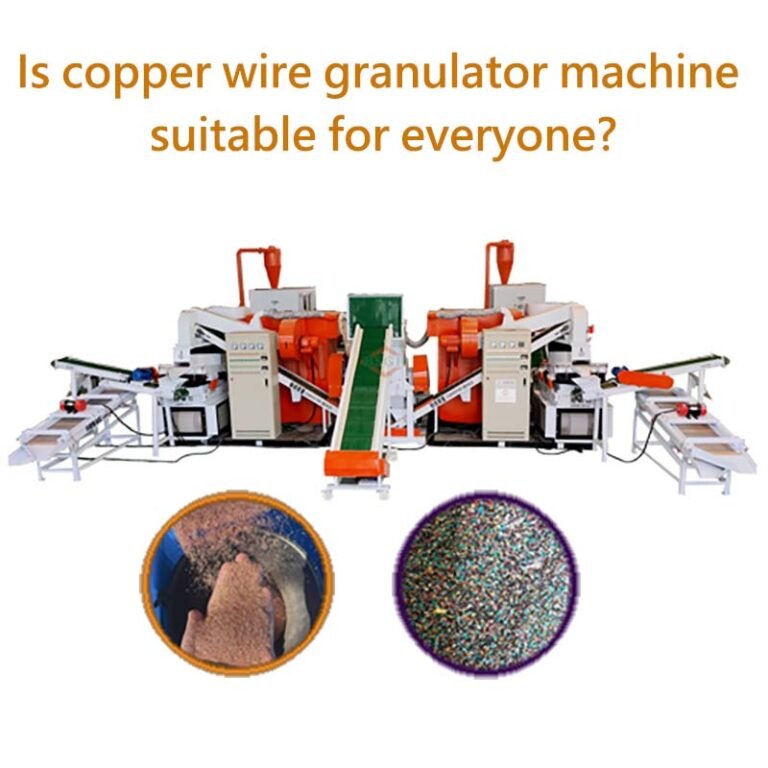

8:Dry Copper Wire Granulator (most popular and widely used till now)

The method of dry physical separation refers to operating without the need for water or other chemical liquids in the separation process. Some older methods of wire recycling involved wet processes that used water to separate the copper from the insulation, but dry copper wire granulators use mechanical vibration and air separation techniques, making them more environmentally friendly and efficient.

This method mainly uses a copper wire granulator machine to process, this is the most advanced recycling method currently available. This method aims to achieve the separation of copper and plastic by crushing scrap cables, adopt air and vibration separation techniques to obtain pure copper particles and plastic particles. The recovery rate can reach as high as 99.9%. Dry copper wire granulators are commonly used in recycling plants and facilities to recover valuable copper from discarded or scrap wires and cables. The recovered copper can then be melted down and reused in various industries, including electronics, construction, and manufacturing.

BSGH, as mentioned before, is a renowned supplier of copper recycling machines. Our copper wire granulator machines dominate 70% of the sales market in China. What makes our equipment stand out?

This preference can be attributed to the numerous strengths and advantages our machines offer in comparison to others in the market as follows.

High Capacity & Low Energy Consumption

Check out the list! BSGH offers mainly three types of energy-efficient and low-energy consumption dry copper wire recycling machines for industrial use. Each type covers a wide range of capacities and is equipped with a variety of machines. This comprehensive selection represents the most complete range of machines in this field. Choose and click on the link that matches your specific needs to learn more. You can also select different models of copper wire granulators based on the number of cables you need to process.

|

Type |

Capacity |

| Large Copper Granulators |

>700KG/H |

| Middle Copper Granulators |

300~700KG/H |

| Small Copper Granulators |

70~300KG/H |

Advanced Technology

These machine has undergone continuous enhancement, updates, and refinement. Using high-quality materials and exceptional durability. Throughout this process, copper will remain clean and not oxidation. As a result, it can be sold at premium prices, contributing to improved customer profits.

Simple Operation

The working principle of the copper granulator machine involves shredding crushing and separating scrap cables. Once the waste cables are fed into the machine, the entire process is carried out automatically, requiring only one worker for operation, this significantly saves labor and cost.

Customization Options

Our machines can be designed to meet specific recycling requirements. Whether it’s the size or capacity of the machine or the types of wires or special cables being processed, our equipment can be adjusted accordingly. Feel free to consult us.

Economic Value

BSGH copper wire granulator machines are sold at factory prices, with no middleman, best and cheap price compare to overseas granulators.

Environmental Protection

Equipped with a dust collection system and devoid of burning or wastewater, the dry physical separation process can achieve complete separation without generating any harmful gases. The entire recycling process has no dust pollution.

Conclusion

In conclusion, many of the methods described above have already been obsoleted. Currently, the most commonly used and popular methods for recycling copper wire are automatic copper wire stripping machines and dry copper wire recycling machines. To efficiently recycle a substantial quantity of copper wires, BSGH provides you with a variety of complete machine types.

so, I think you must understand how to recycle copper wire, also may I know which method you will choose? Leave me message here, we talk more.