Almost every household in the world has a refrigerator. When an old refrigerator is discarded, do you choose to throw it away or recycle it?

When disposing of an old refrigerator, you have two primary options:

- You can sell it directly for immediate cash, which is a straightforward approach for personal disposal.

- Alternatively, for potentially higher returns, the refrigerator can be professionally dismantled and recycled. Over 90% of a refrigerator’s materials, including its steel body and internal copper coils, are valuable and recyclable. However, recycling a fridge is a complex process, not as simple as discarding it in a bin. It requires professional handling by specialized recycling companies that will properly dismantle the unit to recover these materials, as scrapping a refrigerator is a professional task.

So, what materials in your refrigerator are worth recycling? How do you recycle them? Let’s find out.

What Makes an Old Refrigerator Worth Scrapping?

Refrigerators contain many valuable materials that can be recovered and reused when processed properly. Below are the 6 key components that hold the highest recycling value:

1. Refrigerant

Refrigerants like Freon are essential for cooling, but they’re also harmful to the environment if released improperly. While they don’t hold scrap value themselves, professional technicians can safely extract and recover them.

2. Compressor

The compressor is one of the most valuable components inside a refrigerator, it contains a lot of copper windings. If you can recycle these copper windings effectively, it will bring you ideal profits.

3. Cable

Refrigerators include copper wiring for the power supply and internal functions. These cables are worth recycling due to the copper content, which retains a high market value. They can be processed by cable granulating machines to extract clean copper.

4. Radiator

Refrigerator radiators are typically made of copper tubing and aluminum foil. Both metals can be recycled very well if treated appropriately.

5. Steel

The outer casing, internal structural components, and many small parts are made of ferrous metals like steel. It is 100% recyclable and widely accepted at scrap yards. Some high-end or older models may also include stainless steel elements.

6. Plastic

Although refrigerators contain less plastic, they can be recycled and made into new plastic products, ensuring maximum profits.

How Do I Disassemble a Refrigerator for Scrapping?

To prepare a refrigerator for recycling and the extraction of its valuable components, it’s crucial to disassemble it safely and correctly. Below, we present the 8 steps for scrapping a refrigerator, including guidance on tasks that necessitate professional expertise.

Step 1: Unplug and let the refrigerator sit for at least 24 hours.

This gives the system time to defrost, stabilize internal pressure, and helps make the removal process safer.

Step 2: Remove refrigerant.

Removing refrigerant is not a DIY job—it must be done by a licensed technician using professional recovery equipment. In most countries, it’s illegal to release refrigerant into the air, so please contact a qualified service provider before beginning any disassembly.

Step 3: Remove all shelves, drawers, and interior fixtures.

Take out all removable parts inside the refrigerator and freezer compartments, such as glass or plastic shelves, crisper drawers, door bins and racks. These parts can often be recycled separately as plastic or glass, and removing them makes the rest of the unit easier to break down.

Step 4: Remove door hinges.

Using a screwdriver or wrench, unbolt the hinges that attach the doors to the main body of the refrigerator. This step not only makes the unit lighter and easier to manage but also prevents safety hazards.

Step 5: Remove magnetic door seals

Peel off the rubber door seals. These flexible gaskets often contain magnets and may be recyclable, depending on local facilities.

Step 6: Remove the compressor

The compressor is typically mounted at the bottom rear of the fridge and attached with bolts and copper lines. It is one of the most valuable components, as it contains copper and aluminum.

Step 7: Remove copper wires

Check for wire bundles behind or underneath the unit. Cables are also one of the most valuable parts of an old refrigerator. You can collect them and recycle them with professional equipment.

Step 8: Remove the scrap radiator

Radiators are usually located at the back or bottom of the fridge. Radiator recycling machines can separate the copper tubes from the aluminum foil, allowing both metals to be recycled.

How to Recycle Old Refrigerators?

Recycling old refrigerators is usually the most profitable. But for individuals, if you only have one or a few refrigerators, we do not recommend that you buy professional equipment to recycle them. You can sell your old refrigerators directly to the scrap yard, and you can get about $15 to $50 per unit, depending on their weight, condition, and local market price. Or you can disassemble the refrigerator as we mentioned above and sell the parts separately to get more profits.

For recycling companies, we strongly advise you to invest in specialized recycling equipment to effectively process individual refrigerator parts or whole units, thereby maximizing material recovery and profitability. As a premier manufacturer in metal recycling technology, we highlight our top-performing equipment for your consideration. Our offerings include both standalone machines and complete recycling plant solutions, allowing you to select the best fit for your operations.

1. Compressor

The compressor is the heart of the refrigerator, it is rich in copper winding. However, its shell is very hard, making it difficult to recycle. BSGH Granulator specially designed BSCC compressor cutting machine to help you easily break the outer shell.

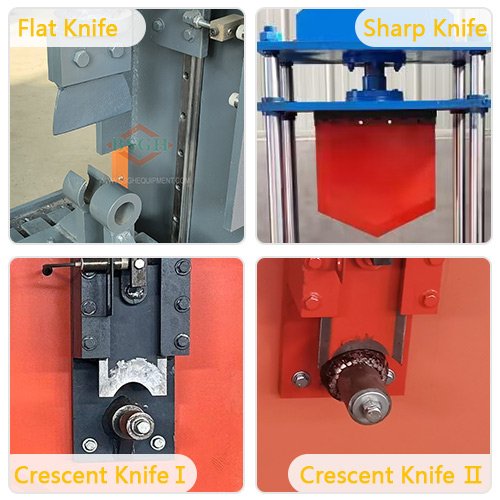

Blades compressor cutting machine

The BSCC compressor cutting machine can handle compressors with a length of more than 15 cm and an outer diameter range of 12-26 cm. When using it, you only need to fix the compressor on the rotating platform, and 4 high-quality blades will automatically cut it, and it only takes about 40 seconds to easily cut the shell.

Plasma compressor cutting machine

After removing the outer shell, you can use our BSC Electric Motor Dismantling Machine to pull out the copper windings. It can handle motor stators with an inner diameter greater than 4cm and an outer diameter less than 12.5cm. BSC Electric Motor Dismantling Machine has a very high cost-effectiveness and is the best choice to help you recycle almost all kinds of motor stators and quickly make a profit.

2. Scrap Cable

We highly recommend investing in a copper wire granulator—an efficient and versatile solution for processing not just refrigerator cables, but also household wires, automotive wires, communication cables, and various mixed scrap wires.

Our machines are especially effective for cables with a diameter of less than 25mm, making them ideal for a wide range of recycling applications.

Here, we recommend 3 best-selling models—small, medium, and large—to suit different processing needs. You can choose the right machine based on the quantity of scrap wire you handle.

- BS-D75 small copper granulator machine

- BS-D75 is our smallest three-phase electric copper granulator, with a processing capacity of about 70kg/h. Despite its small size, it can accurately separate copper particles from plastic insulation, with a recycling rate of 99.9%, making it ideal for recyclers with a small amount of waste cables.

- BS-N125 copper wire recycling machine

- Our middle BS-N125 copper wire recycling machine can process 300-500kg of waste wires per hour. It is popular in many countries such as the United States, the United Kingdom, Japan, Malaysia, etc. According to feedback from many users, BS-N125 copper wire recycling machine can still maintain stable performance under high-intensity use for many years. The copper particles it recycles are 100% pure without any impurities.

- ECO1000 cable granulator

- The ECO1000 cable granulator is the most cost-effective model among BSGH Granulator’s large copper wire granulators. It is equipped with 2 air separators, 4 vibrating tables, and a processing capacity of 1000kg/h. If you are a medium-to-large recycling company with a large amount of scrap cables and a stable source of cables, it is very appropriate to invest in an ECO1000 cable granulator.

3. Radiator

BS-1200P radiator recycling machine

BSGH Granulator is the inventor of the radiator recycling machine, and we have the invention patent. Our BS-1200P radiator recycling machine is the most advanced and mature radiator recycling solution on the market. It can directly process 1-2 layers of flat, regular, non-curved radiators. If you need to process multiple layers of radiators, you can use it with a band saw.

The above information are all recycling solutions for single parts of the refrigerator. If you want to pursue higher efficiency and directly recycle the entire refrigerator, we also provide a large refrigerator recycling production plant.

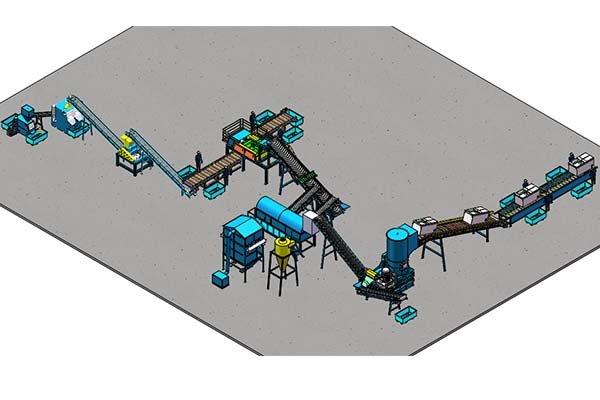

4. The whole refrigerator recycling solution

Refrigerator Recycling Line is engineered to recover valuable materials from whole refrigerators through an advanced process of crushing and separation. Just extract the refrigerant and disassemble the compressor in advance, and other entire unit can be fed into the machine for efficient, automated processing.

This powerful system offers an impressive processing capacity of 2,000–3,000 kg/h, turning your scrap refrigerators into clean, pure copper granules, aluminum granules, iron particles, and non-metallic materials, saving you significant time and labor.

If you choose our refrigerator recycling line, we will also provide free factory design, circuit design, machine placement design, and other thoughtful services.

If you are in the market for these machines, I believe our machines must can help you more, it’s really one machine can take you more profits, just trust us, we won’t let you down.

Conclusion

Discarded refrigerators are far from “waste”; their compressors, cables, radiators, metal shells, and other parts all have high recycling value. Whether you sell the refrigerator directly to scrap yards, disassemble it and sell each part separately, or recycle the whole refrigerator, it can bring you considerable profits.

As a high-end metal recycling equipment manufacturer, the machines provided by BSGH Granulator can not only help you recycle individual parts of scrap refrigerators, but also quickly turn the entire refrigerator into a “treasure” to maximize your profits. If you also want to scrap an old refrigerator and make money, you can contact us at any time.