Hydraulic Alligator Shear Machine

✓ Powerful shearing capability, maximum shearing force reaches 5000KN, easily shearing metal.

✓ Reliable and stable, always maintains excellent performance during high-intensity continuous work.

✓ We provide a full range of models from small to heavy hydraulic alligator shears.

Leading Hydraulic Alligator Shear machine Manufacturer

Most of Hydraulic alligator shear machine is mainly adopt hydraulic system as it’s power to cut all types of material, safe and high torque. If you want to shrink the size of the material, this kinds of shear machine is a good choice for you, cheap and easy to opearate.

Why do we need hydraulic alligator shear?

What can BSGH hydraulic alligator shear do?

The electric motor used in the hydraulic system of BSGH machine is very powerful which will drive the hydraulic system to cut the objects and the material used in it is very hard and wear-resistant perfectly making the cutting process smooth and easy.

There is no pollution in the whole process, so it is no need to worry about violating local environmental protection policies and the environment where operators worked in is also enhanced greatly. These machines have been on the market for many years achieving testament to its quality and durability from customers all around the world. Moreover, it is relatively easy to maintain, ensuring long-term use and cost-effectiveness.

High-quality hydraulic alligator shear for sale

Hydraulic alligator shear machine is ideal for reducing the size of materials. They are not only low in price, but also have high shearing pressure. Driven by a hydraulic system, they can easily shear various hard metal materials into small pieces. After shearing, the material is smaller in size, which not only simplifies the recycling method, but also makes transportation and storage more convenient and saves costs.

BSGH Granulator scrap metal hydraulic alligator shear have stable performance, safety, and reliability, low failure rate, and low maintenance cost, and have been unanimously recognized in the scrap metal recycling market.

Hydraulic alligator shear types

Depending on the size of the processing capability, the thickness, and the hardness of the material, customers require products with different performances. We have various models of hydraulic alligator shears to meet all customers’ needs.

The main differences between the following products are oil pumps, oil tanks, and tonnage.

The larger the oil pump of the machine, the greater the flow rate. The larger the fuel tank, the faster the machine will dissipate heat. Larger tonnage means greater shearing force and can cut thicker steel.

But the blades of each machine are of high quality, wear-resistant, and durable, and are worth choosing.

| Machine | AS-60 | AS-250 | AS-630 | AS-1000 | AS-1200 | AS-1600 | AS-2000 | AS-2500 | AS-3150 | AS-4000 | AS-5000 |

| Maximum Shearing Force(KN) | 60 | 250 | 630 | 1000 | 1200 | 1600 | 2000 | 2500 | 3150 | 4000 | 5000 |

| Maximum Pressing Force(KN) | / | / | / | 196 | 200 | 100 | 260 | 260 | 420 | 420 | 420 |

| Shearing Speed(Times/Min) | 7-8 | 10-12 | 7-8 | 9-16 | 10-15 | 12-20 | 7-12 | 7-12 | 7-12 | 5 | 6-9 |

| Blade Length(MM) | 300 | 300 | 600 | 600 | 600 | 700 | 800 | 1000 | 1200 | 800 | 1600 |

| Maximum Blade Opening(MM) | 160 | 160 | 280 | 335 | 300 | 320 | 380 | 480 | 520 | 700 | 886 |

| Motor Power(KW) | 3 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 15 | 18.5 | 30 | 22 |

| Oil Pump Outflow(ml/r) | 5.2 | 25 | 25 | 40 | 63 | 80 | 160 | 63 | 80 | 160 | 160 |

hydraulic alligator shearing machine usage

Alligator shear machines can cut many different kinds of material, such as objects with special shapes such as bicycle frames, wooden frames, etc.

The other is section steel, such as square tubes, round tubes, channel steel, and so on. It is widely used for cold shearing of round steel, square steel, angle steel, I-beams, plate steel, steel pipes, and other scrap materials, as well as for cutting fixed-length hot-rolled small steel, Steel rolling mill sections, cutting of scrap steel bars, small briquettes, steel plates, scrap cables and other heavy scrap materials in metallurgical furnaces.

Also, fit for plastic and wooden pallets, and many other light materials or heavy metals.

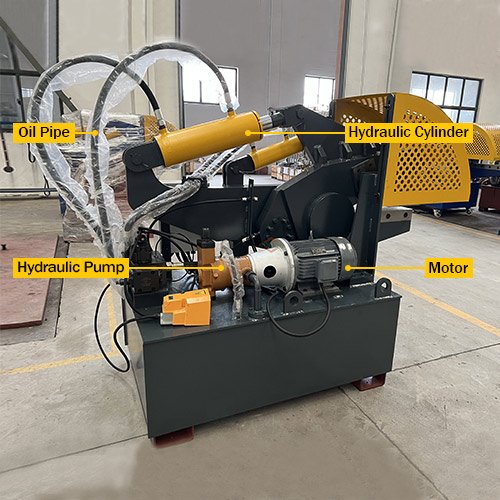

hydraulic alligator shear machine structure

BSGH Granulator Hydraulic alligator shear machine have 2 kinds, one is integrated types(mainly for small shears pressure under 100T), another one is split types(mainly for big pressure above 100T); all shears is mainly composed of mechanical part, electronic part and hydraulic part.

- Mechanical part: It mainly consists frame, blade bracket and hydraulic cylinder and so on.

- Electronic part: There are two parts include motor control circuit and motion sequence circuit.

- Hydraulic part: Hydraulic part is a set of pump house, valve house ,cylinder and pipeline.

Following images show detail structure of our AS-630 Hydraulic Alligator Shear Machine.

The following image gallery presents the main components of the machines shown in the above two structural diagrams.

How does a hydraulic Alligator shear machine work?

In terms of working principle, Our Hydraulic Alligator Shear Machine utilizes hydraulic pressure provided by a hydraulic pump to drive hydraulic cylinders to generate lever pressure. After pre-pressing and locking, the shearing operation is achieved under the shearing pressure of the main pressure cylinder acting on the moving blade and the fixed blade.

The whole process can be divided into two steps.

First step: The operator should place the object on the cutting platform. Then the pressure plate will be laid down to fix the object and the blade will cut it.

Second step: Each time the blade makes a cut, the operator should put forward it a certain distance depending on how long the cutting part should be.

Note: Different models of hydraulic alligator shears can cut different types and thicknesses of objects. Take AS-1200 Alligator Shear Machine as example, the size of different shearing materials are as following:

- Channel Steel: 180*70*6MM

- Angle Steel: 100*100MM

- Round Steel: Ø60MM

- Steel Plate: 200*200MM

- Square Steel: 45*45MM

alligator shear machine videos

Below are some videos of our various alligator shears in action. They can continuously shear scrap metal materials in an automatic mode. Whether a small home model or a heavy-duty industrial model, they can maintain high cutting efficiency and smooth operation, making them your best choice for size reduction. Some of our customer is very happy to share his operating video of AS-5000 Hydraulic Scrap metal alligator shear machine with us. From the video, we can see the hydraulic alligator shear cut the objects very smoothly.

BSGH Granulator -Your most reliable supplier

We provide customized hydraulic alligator shear machine recycling solutions customizable to your industrial or home needs and site conditions, offering the most suitable equipment configuration for you. Welcome to visit our factory!

Come and Enjoy an AR journey to BSGH ➜

Why choose us?

Our machines have been constantly updated, their performance has been steadily improved and is more cost-effective than many machines on the market. Our hydraulic alligator shear machine has different types, besides integrated type and split types for each kinds also have different power and pressure for you to choose.

Still worried about too many machine models to choose from? It doesn’t matter, our professional staff will serve you, and they will make the most suitable purchase plan for you based on your processing needs and budget.

We also provide after-sales service to ensure that you can use it correctly. I believe we are worthy of your choice.

get a free quote now!

Our online consulting experts bring peace of mind to your complex customization needs. Learn more about how we can help you turn waste into treasure. Email us now.

This form will allow you to send a secure email to BSGH Granulator.