Industrial shredder machine manufacturer

BSGH Granulator offers a comprehensive range of industrial shredder machines designed to reduce the size of various materials, including scrap metal, wood, plastic, rubber, etc, our shredder machine shaft is rotary and have one shaft, 2shafts, 3shafts or 4shafts. With excellent shredding capabilities, our machines are widely used in the fields of building materials, metallurgy, chemicals, etc., and they are especially becoming indispensable equipment in the recycling industry.

Your premier industrial shredder machine provider

Our Professional

We are the largest metal recycling machine manufacturer in China, with a wide range of high-quality industrial shredder machines for different fields use. We are committed to creating industrial shredders that lead the industry standard in both performance and efficiency, while continuously optimizing their structure to significantly reduce the risk of failure.

Our Footprint

Our industrial shredder machines stand out in the fierce market competition with their high torque, high safety, durability, and affordability, and have become the first choice of customers in Thailand, Italy, Mexico, Argentina, the United Kingdom, etc. Every day, more than 500 BSGH Granulator industrial shredder machines are running stably around the world, processing various raw materials into manageable sizes, helping our customers save a lot of space and transportation costs.

Various industrial shredder machine for sale

We have created many different types of industrial shredders, these shredder have different quantity shafts, every shaft will rotary shearing in low speed or high speed to finish the shredding tasks, they have different characteristics and are suitable for different raw materials. You can refer to the following information to make a better choice.

Dual-shaft shredder

Dual-shaft shredder is the most common type of industrial shredder machine on the market. Our dual shaft shredder greatest feature is versatility. Whether plastic, tires, metal, or appliances, it can reduce their size quickly and easily.

Our dual-shaft shredder is equipped with two shafts fully loaded with blades. When the machine is activated, the shafts rotate in opposite directions, driving materials into the gap between them. This counter-rotation generates continuous compression and shredding, efficiently breaking down materials into smaller pieces.

- Small single-motor shredder

- Double motors shredder from small to big(#300, #400, #500, #600, #630, #800, #1000, #1200, #1400, #1600, #1800, #2000, #2200, #2400, #2600)

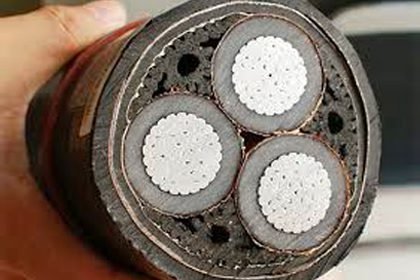

Single-shaft shredder for scrap cables

An affordable and efficient single-shaft shredder with strong power and speed to complete a wide variety of scrap cable shredding tasks. This machine is a patented product of BSGH Granulator, which is specially used for shredding scrap cables. If you are specialized in scrap cable recycling business and need to process a large number of cables, then our special single-shaft shredder will be your best choice for preprocess your scrap cables. It can reduce copper wires to 6-15cm, protect the main shredder blade, extend the service life of the whole machine, and greatly improve the working efficiency.

- Power: 110KW

- Capacity: 2-5T/H(support custom)

- Sieve Diameter: 65-75MM(optional)

- Max Feed Size: ∅30MM

Single-shaft shredder for plastic

Our single-shaft plastic shredder is a powerful solution for efficiently and effectively reducing the size of various plastic waste. By processing bulky plastic materials into smaller, manageable pieces, it helps save significant storage space and lowers transportation costs. The shredded plastic particles can be recycled and reprocessed into new plastic products, creating opportunities for added profitability and supporting sustainable practices.

One of the standout features of our shredder is its flexibility. By simply replacing the screen, you can easily control the size of the shredded plastic particles to meet your specific requirements. This makes it ideal for diverse applications, from recycling plants to manufacturing facilities. Built with robust construction and sharp cutting blades, the shredder ensures consistent performance and long-term reliability.

Hammer mill shredder

Hammer mill shredder is the ultimate solution for processing large materials and wider processing range. Unlike traditional shredders, it utilizes high-speed rotating hammers instead of blades to crush materials. When materials enter the crushing chamber, they are subjected to powerful impacts from the hammers, effectively reducing their size. A screen located at the bottom of the machine ensures that only particles smaller than the screen size are discharged, while larger materials remain in the chamber for further shredding until they reach the desired size.

- Power: 550KW(can be customized, different material different)

- Capacity: 8-10T/H(have smaller and bigger)

- Rotor Range: 1240MM

- Sieves Diameter: 70MM

Custom your industrial shredder machine

Different industrial shredders can process different kinds of materials, also power are various. Our company also provides personalized customization services for shredding equipment. Contact us and let us know your special request, and our sales staff will provide you with the perfect solution.

What raw materials can you process with our

industrial shredder machine?

Get unique recycling sulotion of your industrial shredder

If you do not know which kind of industrial shredder machine you need to choose or which one is most cost-effective for your raw materials also want to separate various materials directly after shredding, we offer customized separation systems. Simply provide us with pictures of your raw materials and processing capacity, and our team will design the most suitable solution tailored to your specific needs, ensuring maximum efficiency and performance for your operations.

Advantages of our industrial shredder machine

High Efficiency

The fully optimized design ensures the high efficiency of our machines. The wide design of the feed port facilitates the rapid input of large amounts of materials, and the reasonable structure of the internal crushing chamber enables the materials to be fully crushed into particles of uniform size in the shortest possible time.

Fully automation

Fully automatic machine, only 1-2 operators can complete the entire operation, and the operators only need to feed and collect the final product, which can help you significantly reduce labor costs.

Unique screen

We have adopted a unique screen replacement design, which simplifies the steps required for screen replacement. The screen replacement can be completed in a shorter time, reducing downtime and meeting different sizes of crushing needs in a short time.

High Quality Material

Made of high-quality, high-strength premium raw materials, especially the vulnerable parts, blades and hammers are made of Mn steel, and manganese plates, and have undergone professional heat treatment. They not only have a good crushing effect on high-hardness materials but also have excellent wear resistance. They can maintain extremely low wear during long-term high-intensity operations and are durable, their service life far exceeds 90% of the same type of machines on the market.

Exceptional Safety Design

Our industrial shredder machine is designed with exceptional safety features to ensure secure and worry-free operation. The shredding chamber operates in a fully sealed state, effectively keeping operators' hands away from the rotating blades and hammers, significantly reducing the risk of injury. The machine also has an advanced PLC control system, allowing for real-time monitoring and precise operation. In case of any irregularities or emergencies, the machine can be stopped immediately with a single command, enhancing overall safety.

How to choose a suitable industrial shredder machine

There are many types and models of BSGH Granulator shredders, and each machine has unique characteristics. So, how do you choose a shredder that best suits your needs?

The following three steps can help you make a quick judgment, or you can contact our staff directly and send us pictures of your raw materials, and we will recommend the most suitable machine for you.

Types of raw materials

First, you need to select the type of shredder based on the materials you plan to process. For example:

- If you are primarily handling cables, single-shaft cable shredder is an excellent choice due to its specialized design.

- If your materials consist largely of plastics, a single-shaft plastic shredder will deliver the best performance.

- For large and bulky items, such as car shells, we highly recommend our hammer mill shredder, which is specifically engineered for heavy-duty tasks.

- If your materials are varied and include different types, a versatile dual-shaft shredder is the ideal solution, offering flexibility and efficiency across a wide range of applications.

Quantity of raw materials

Once you have decided on the type of shredder, the next step is to select a specific model based on the amount of material you are dealing with. Processing capacity is a key factor in choosing the right machine. Small models are ideal for lower output requirements, while larger machines are designed to handle high-capacity operations, ensuring faster processing times and greater overall productivity.

- If your material volume is small and the supply is erratic, a small machine will be sufficient to meet your needs.

- However, if you need to process a large amount of material with a steady supply, our larger models will help you maximize your efficiency and profitability.

Personal customize service

We provide flexible customization services, from blade material, screen size, voltage, and machine color, to auxiliary equipment, and separation systems, our professional designers can create a unique and optimal solution according to your requirements.

- We provide factory design drawings, including line design, as well as machine location placement and layout.

- For machine voltage, we can do 220V, 380V, 400V, 415V, 440V, 480V, 600V; 50HZ and 60HZ.

- Color may be more meaningful for some customers, for your lucky color maybe will take you more wealth and happiness.

- For most of the companies in the market, they are only provide shredding, but we also provides separation solutions.

Why choose us?

As a leader in the metal recycling industry, BSGH Granulator is committed to providing each customer with the most perfect industrial shredder to help them simplify operations, reduce costs, and increase profits. Our shredders use the best raw materials, the most advanced crushing technology, and efficient power systems to achieve the best crushing effect. You can feel confident in your decision to partner with us, we will support your industrial tasks with the best equipment and services.

Rich experience

With 25 years of experience in the metal recycling market, our technological innovation and manufacturing experience have made our equipment the leader in performance and quality.

Strict quality control

We will conduct multiple quality inspections on each part of the machine during the production process, and a test run before the machine leaves the factory to ensure that it is of high quality before shipment.

Excellent brand reputation

Our machines have won the praise of most customers with their excellent quality and high-cost performance, and we have successfully become the first choice of most customers for metal recycling machines.

Perfect after-sales service

In order to protect your legal rights and interests, we provide comprehensive after-sales services. We provide one-year free warranty, detailed installation, commissioning, maintenance methods, worker training, and lifelong 24-hour online response.

Certifications

working videos of BSGH Granulator

shredder machine

Lets Tell Us About Your shredder machine Needs

Tell us what’s your requirement for shredding. We’ll come up with custom processing solutions that will help you recycle more efficiently and effectively.

- Whatsapp/Viber: 008613772508206

- Email: coppergranulator@bsghrecycling.com

- Website: https://bsghgranulator.com/