high performance scrap Metal shredder

Rapidly shreds aluminum, copper, steel, and other metals

Reduces bulky scrap into manageable particles

Minimizes storage and transport expenses

Ideal as a pre-shredder for recycling production lines

- Various types of scrap metal shredder for you to choose

Why we need scrap metal shredder?

- Crushing various waste materials into manageable-sized particles, which can be easily recycled or processed.

- Turning large and bulky piles into compact, stackable fragments, saving a lot of space.

- Crushed waste is easier to transport, effectively reducing transportation costs.

- Scrap metal shredder can be used as a pre-shredder in the scrap metal recycling production line to protect the main shredder blade and extend its lifespan.

- Realize automated production, reduce manual intervention, and reduce labor costs.

High-efficiency metal shredder by types

BSGH Granulator has designed a variety of metal shredders, mainly including double-shaft shredders, single-shaft cable shredders, and hammer mill shredders, which can handle almost all metal scraps with recycling value. Whether you are engaged in scrap metal recycling, manufacturing, or waste management, we can provide reliable solutions.

Dual-shaft metal shredder is a very common size reduction equipment, which mainly uses two main shafts rotating in opposite directions to continuously squeeze the material, and the blades installed on the shafts to crush the material.

- Offers a broad processing range, almost without restrictions on material, type, and shape. In addition to various metal scraps such as aluminum, copper, and iron, the dual-shaft shredder can also efficiently process plastics, wood, rubber, and other materials.

- The bearing adopts a convenient and simple design, which can quickly remove the moving blades, fixed blades, bearing, and other parts, making it easy to maintain and replace the blades.

- Widely used in industrial waste recycling, electronic manufacturing, wood processing, and other industries.

- You can achieve a better crushing effect by manually reducing the distance between fixed blades and moving blades.

The Single Shaft metal Shredder is specially designed to reduce the size of waste cables to 6-15cm, better for cables with a diameter of less than 30mm. It has an extremely large capacity, with a maximum processing capacity of 5T/H, which can push your production efficiency and operation to a new level.

- Single-shaft cable shredder machine is a patented product of BSGH Granulator, its design and structure are unique.

- Support forklift loading, no longer need manual uniform feeding, saving time, effort, and labor costs.

- Its square blade hook material design is completely designed according to the characteristics of various cables, which solves the problem of the machine getting stuck caused to too much material in the crushing chamber.

- Equipped with a hydraulic auxiliary pushing system., the shredder pushing method is from top to bottom, which effectively avoids the problem of the hydraulic rod not being able to contact the material and the machine idling when less material in the crushing chamber.

Hammer mill metal shredder is suitable for shredding large quantities of large and hard metal scraps. It no longer uses blades to crush metal materials but uses high-speed rotating high-strength, high-hardness hammers to continuously impact metal scraps to reduce their size. If you need to process a large number of materials such as automobile shells, large steel plates, etc., we strongly recommend our hammer mill shredder.

- Very high working efficiency, the processing capacity range is 3T/H-20T/H.

- Hammer mill shredders feature a rugged structure and durable components that enable them to operate for long periods of time in demanding conditions and handle tough materials without frequent wear or breakdowns.

- The main axis is driven by a hydraulic system, which ensures that the machine has high torque and high stability, and is not easy to damage.

- The machine has a large material discharge function. When there are large materials in the crushing chamber, the large materials can be discharged without stopping the machine, effectively protecting the crushing chamber.

scrap metal shredder options

Our scrap metal shredder machines are available in a wide range of models to meet diverse needs and applications. From compact, home-use shredders to large-scale industrial shredding systems, we provide tailored solutions for efficient metal processing and recycling.

Small and Medium Shredders: Ideal for light-duty applications such as household scrap, small workshops, and recycling centers. These machines are easy to operate, energy-efficient, and designed for safety and convenience.

Heavy-Duty Industrial Shredders: Engineered for demanding tasks, our industrial shredders can handle bulk materials including steel drums, car bodies, aluminum profiles, and other large metal waste. They deliver powerful performance, high throughput, and consistent particle size.

Custom Solutions: We also offer customized shredding systems based on specific capacity requirements, feeding methods, and output size.

MS-S300 Metal Shredder

With one electric motors, also is the smallest shredder

MS-D400 Metal Shredder

Single motor or double motors; 5.5KW/11KW

MS-D600 Metal Shredder

Double Motors; 11KW*2/15KW*2/18.5KW*2

MS-D630 Metal Shredder

Double Motors; 22KW*2/18.5KW*2/15KW*2

MS-D800 Metal Shredder

Double Motors: 22KW*2/30KW*2/37KW*2/45KW*2

MS-D1000 Metal Shredder

Double Motors; 37KW*2/45KW*2/55KW*2

MS-D1200 Metal Shredder

Double Motors; 45KW*2/55KW*2/75KW*2

MS-D1400 Model Shredder

Double Motors; 75KW*2/90KW*2/110KW*2

MS-D1600 Metal Shredder

Double Motors; 90KW*2/110KW*2/132KW*2

MS-D1800 Metal Shredder

Double Motors; 132KW*2/160KW*2/280KW*2

MS-D2000 Metal Shredder

Double Motors; 185KW*2/200KW*2/250KW*2/280KW*2

MS-D2400 Metal Shredder

Double Motors;185KW*2/200KW*2/280KW*2

Various scrap metal shredder by applications

Our versatile scrap metal shredder is of low speed and high torque, it can easily shred various metal materials, such as copper, iron, aluminum, scrap home applicance, cars, aluminum alloy windows etc. Its application range covers a variety of industries.

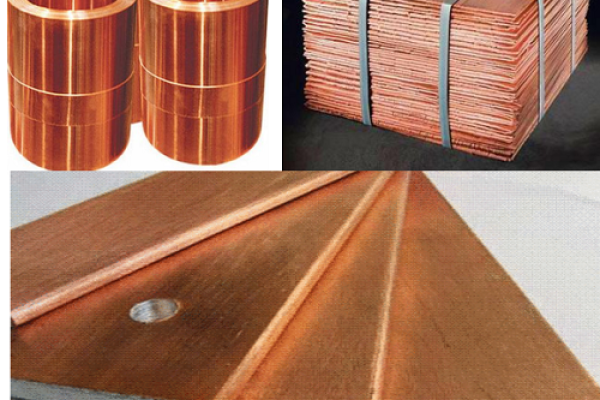

shredder for Copper

Copper tubes, car engines, radiators, copper core cables, transformers, motor rotors, our metal shredder can help you quickly shred these copper scraps, for easier extract valuable copper from them.

shredder for Iron

Car shells, motorcycles, waste bikes, iron core radiators, waste steel, steel plates, steel tubes, BSGH Granulator metal shredder is the best shredding solution for these high-hardness iron materials and steel materials.

shredder for Aluminum

Aluminum core cables, sheets, coils, aluminum steel wires, aluminum-plastic medicine plates, our shredder can easily complete the size reduction tasks of the above aluminum scraps.

shredder for Home appliances

Metal Shredder supports shredding of scrap TV sets, waste air conditioners, used washing machines, household electrical appliances, and other very common raw materials in life.

metal shredder Application fields

Building Materials

Metal shredder plays an important role in the building materials industry. It can reduce building materials such as limestone and cement to the required size to meet production requirements.

Chemical industry

Chemical industry is another important application industry for metal shredders. In the production process of plastics, rubber, and other materials, shredder can shred the raw materials into uniform particles or particles, providing the best raw materials for molding and other processes.

Agriculture

In the agricultural field, our machine is mainly used to process waste such as crop straw, branches, tree roots, etc. In subsequent processing, you can process these wastes into valuable products such as organic fertilizers or feed.

Minerals and Metallurgy

In the minerals and metallurgical industries, shredder machines can crush ores into a particle size range suitable for subsequent processing, thereby improving mineral processing efficiency and resource recovery rate.

Recycling

Metal shredder is an essential equipment in the recycling industry. Reducing various waste materials to manageable sizes, it not only saves a lot of space and transportation costs but also makes the best preparation for separation, recycling, and other steps.

The global sales footprint of our heavy-duty metal shredder machine

Over the years, our metal shredder has helped more than 1,500 customers reduce costs and improve production efficiency. Our machine’s sales footprint covers all over the world, especially in South America, Thailand, Japan, Canada, USA and other places.

Most customers gave us high feedback after receiving the machine, saying that our machines helped them to complete the crushing work easily and simplified their operation process, saving time and effort. Some of these customers soon reached a second cooperation with us and said that BSGH Granulator was their first choice for purchasing metal shredder.

Why BSGH Granulator Is the first choice for most customers

when purchasing metal shredder?

High crushing performance

Metal shredder has excellent crushing performance, it uses an advanced high-power pure copper core motor, which can output strong and stable power and ensure high torque. With efficient crushing technology and innovative crushing chamber design, the machine effectively reduces the retention time of materials and realizes continuous and efficient crushing operations. At the same time, the high-precision screen ensures uniform particles of crushed materials.

High stability

The machine body is made of high-strength thickened alloy material and precision processing technology, which ensures the close fit and balance between various parts, and enhances its load-bearing operation capability. During long-term, high-load operations, our metal shredder can always maintain a stable operating state.

High durability

Built to last, the thick wall and stable frame structure of our machine provide solid support for the internal core components, effectively preventing the deformation or damage of the machine body caused by long-term operation, greatly extending the service life of the equipment. Even the vulnerable parts are made of highly wear-resistant materials, whether blades or hammers, which can ensure minimum wear under high-intensity work.

Low maintenance requirements

During the design process, we prioritized low maintenance costs, using a simple and sturdy structure to reduce maintenance needs. The compact body saves floor space while ensuring sufficient crushing space without compromising shredding performance. Each component is carefully designed for easy maintenance, requiring only basic lubrication and regular inspection to maintain long-term stable performance. Under normal operating and maintenance, the machine is highly reliable and generally does not fail. Even if a failure occurs, repairs and parts replacement can be done quickly and easily to ensure minimal disruption to operations.

How does our scrap metal shredder machine help customers?

We will share a real customer case so that you can better understand us and our machines.

Customer from:

UK, operating a large scrap metal recycling station

Challenge:

1. He needs to process a large amount of scrap materials such as car shells, old home appliances, and large steel plates, but the existing machines are inefficient.

2. His old machine is often blocked and requires constant maintenance, resulting in production delays and increased labor costs.

BSGH Granulator Solution:

Dual-shaft scrap car shredder

Results:

Our scrap metal shredding machine can process about 10-15 tons of scrap per hour, helping our British customer increase production by about 40%. And there is almost no clogging problem when processing large materials such as scrap cars, which greatly shortens downtime. In just one month, our machine helped customer increase profits by more than 70%.

Customer evaluation:

“This shredder has transformed our operation. It has turned many old cars that were piling up in my yard into profitable parts. It runs stably and smoothly, and saves us a lot of time and money.”

Ready to upgrade your metal recycling process? Contact us now to get the best quote.

Lets Work

How To Get Metal Shredder From Us

Tell us the quantity and type of your raw materials, and your requirements for the metal shredder, we will recommend the most suitable model and we will assist you in every step of the purchasing procedure.

Inquiry and Consultation

Send us pictures of your raw material, and we will discuss the most suitable shredder machine type and model with you.

Customization and Quotation

If you have special requirements for metal shredder, such as a customized separation system, we will quickly create a perfect solution based on your actual needs and quote you the lowest price.

Order Confirmation and Manufacturing

Once we receive your advance payment, we will immediately send your request to the factory and start production and update you on the production status of the machine in time.

Delivery and After-Sales Support

After production completed, we will send you a trial video of your metal shredder, you can pay the balance after confirming the quality, and then we will arrange the shipment. We support free repair or replacement of non-human damaged machine parts within 1 year.

Lets Tell Us About Your metal shredder Needs

Tell us your scrap metal shredder requirements, and we’ll tailor solutions to enhance recycling efficiency and performance.

- Whatsapp/Viber: 008613772508206

- Email: coppergranulator@bsghrecycling.com

- Website: https://bsghgranulator.com/

More machine pictures and videos you can check below

Following are the different metal shredder for your reference.

video display

The following are the videos of our industrial metal shredder. You can see that the sturdy main shafts and blades work together to shred the metal scraps into uniform, small pieces quickly. The shredding process is smooth and efficient, and the machine generally does not get stuck. In addition, the machine runs smoothly, without obvious vibration and noise, making it the best choice to complete various shredding tasks.