What can be recycled?

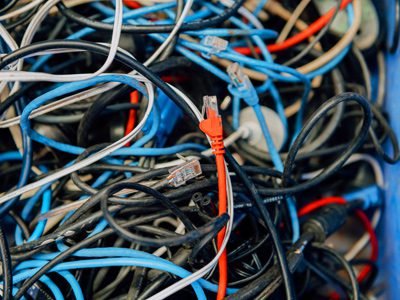

The copper cable granulator machine is mainly used to recycle copper metal from scrap wires. The wires that can be recycled by it includes communication wires, power cables, soft wires, etc.

Communication cables refer to wires used to transmit data, sound, images and other information. The specific types of communication wires are network cables, telephone cables, high-definition cables, USB cables and so on, we have our configurations for our copper cable granulator machine to process this kinds of wires to reach the best effect.

Power cables are used to transmit and distribute electrical energy. They can be divided into copper cable and aluminum cable according to the category of conductor. For this kinds of cables, it’s very easy to process, but you need to distinguish the advanced copper cable granulator yourself, because one real good machine can take you more profit in a fixed time.

Flexible wire is a kind of wire with high softness, which is usually used in scene that requires bending or folding, such as electronic product wiring, medical equipment, toy decoration etc. Most of this kinds of wires is thin and have the higher requests for machine performance, but our machine can recycle it very well, you can consult.

The most special one is armored cable, in order to allow the wire to function better in coal mines, petrochemicals, rail transit and other hard working situations. A layer of iron sheet will be added outside the insulation layer to enhance the wear and pressure resistance of the cable. For this type, we have designed a new armored copper granulator machine to recycle it.

How does it process waste wires?

The working principle of copper granulator machine can be summarized in two words: crushing and separation. The purpose of crushing is to cut the waste wire into small pieces to facilitate subsequent separation. The aim of separation is to completely separate copper and plastic in order to get high purity copper product. Conveyor belts are used to connect each part of the machine.

The machines responsible for crushing include shredder and crusher. Shredders on the market generally adopt a double-shaft structure, is used to cut waste wires into pieces, and the crusher is used to crush these pieces into particles. They work together to make an adequate preparation for separation.

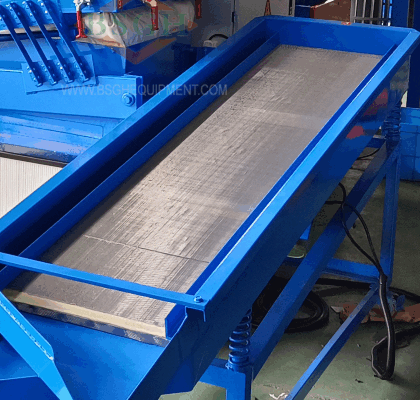

The machines responsible for separation are air separator and vibrating table. Air separator uses the density of substances to separate. The vibrating bed take vibration to further separate metal and plastic. These two machines work together to maximize the effect.

If there are iron substances in the waste wires, a magnetic separator should be installed on the conveyor belt to absorb the iron substances mixed in waste wire pieces through magnetic force.

When the diameter of your waste wires is as thin as a hair, or they are all miscellaneous wires, you can choose to install an electrostatic separator, which can better separate plastic and metal through the difference in material charge.

In addition, you don’t have to worry about the machine violating your country’s environmental protection treaties, because our machines are also equipped with dust collection systems that can effectively reduce environmental pollution and create a good working condition.

What will you get?

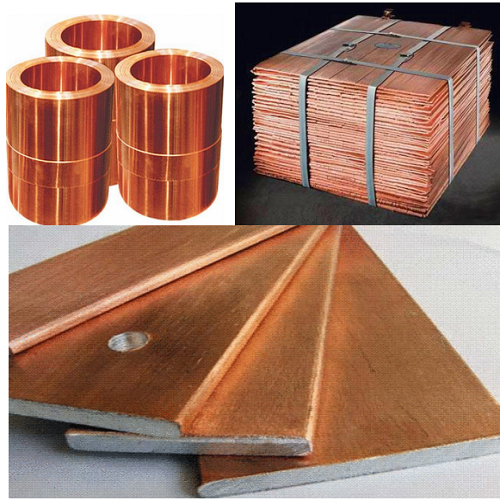

Through recycling, we will get copper products that are like rice. So how to distinguish the quality of copper rice? There are three methods for your reference.

First, you can observe the appearance of copper rice. Generally speaking, the purer the copper, the brighter the appearance and the color is close to golden yellow. From the picture below, we can see that the final product has a strong texture, luster and uniform color.

Second, you can touch the surface of copper rice with our fingers to feel whether their surface is smooth, clean, and whether there is any damage on them; from this, you also can adjust the coppper cable granulator machine quality from copper particles details, if the surface is smooth and the cutting point is keep the original color, then you will know the machine you used is a good machine. Vice verse, if the surface is rough and the cutting point become new and bright, then you know the machine you used is bad one, the copper loss will be bigger.

Third, you can grab a handful of copper rice and use a magnet close to them. High-purity copper products do not have iron substances, so they will not be attracted.

What’s special about our product?

Various Kinds of Machine

We have a wide range of copper cable granulators, according to the processing capacity, they can be divided into three types: large, medium and small. There are also many models in these three types which can surely meet the diverse needs of customers. Not only that, we have many machine accessories, such as spare blades. We also have related devices of the machine, such as hydraulic briquetting Machine which can press the copper rice into a cylinder shape for easy recycling in the furnace.

Multiple Choices

Our machines have a variety of combinations and it can be assembled according to the type of wire, the processing capacity needed and the material inside the wire.

- When iron material is included in wires, magnetic separation should be installed.

- If the wires are too messy and thin, try to install an electrostatic separator.

- If the wire being processed is armor wire, you need an armor wire copper granulator machine to help you.

Innovative Technology

Our experts and technical team continue to learn new knowledge and improve their professional capabilities devoting themselves in innovating machines to meet new market needs. For example, we use air separators to replace the high-pressure separator which can achieve better separation results. We have also launched a new product, armor wire copper granulator machine, which has been mentioned above, can handle armor wire that ordinary copper granulator machines cannot do. You can get details from the above details.

We also launch the new products for ACSR cable recycling machine, video as follows:

With precision engineering and advanced technology, the ACSR Cable Recycling machine efficiently separates aluminum and steel components, ensuring optimal recycling and reuse. Increase your recycling efficiency and maximize resource utilization with our cutting-edge Copper Granulator Machine.

We strive to provide customers with better and higher quality machines. If you want to know more about our machine, you can contact us any time!