wire and cable recycle machine

Wire and cable recycling machines are the most advanced professional equipment on the market for recycling waste wires. These machines are capable of processing a variety of different sizes and types of waste wires into whole copper wires or clean pure copper particles. They range in size and capacity, catering to recycling operations ranging from small businesses to large industrial facilities. It can be said that wire and cable recycling machines are essential in the recycling industry due to their strong construction, dependability, and high operational efficiency. Since they use physical separation technology and are equipped with advanced pulse dust collection equipment, these environmentally friendly machines can meet global environmental protection standards, supporting you in using our wire and cable recycling machines worldwide.

Our copper wire granulator Machines

Best wire and cable recycling solutions

BSGH Granulator is the first wire and cable recycling machine manufacturer in China. We have our own professional designers and machine manufacturing factory, and we are committed to providing cost-effective machines to all customers. We mainly provide two kinds of machines for recycling waste cables: automatic stripper machines and copper granulator machines. They have different application ranges and applicable groups, but they are both a combination of high performance, high durability, high safety, and low cost. Whether you value the performance, efficiency, durability, or price of the machine, you can find an excellent solution at BSGH Granulator.

Copper granulator machine

The copper granulator machine mainly recycles waste cables by crushing and separating. First, the crusher crushes the waste cables into 3~5mm copper and plastic mixed particles. Then, these mixed particles are processed by an air separator and a vibrating table and finally separated into pure copper particles and plastic particles. Our copper granulator machine adopts the most advanced technology to solve the problem of high copper loss in dry copper wire recycling machines, with a recovery rate of up to 99.9%.

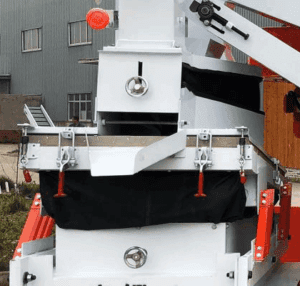

Structures of copper granulator machine

The structure of copper granulator machine is mainly composed of five parts: main crusher, airflow separator, dust collection, vibrating table, conveyor belt, etc. In addition, some customers may configure pre-shredder, magnetic separator, electrostatic separator or other devices to improve the recovery rate according to their own production needs.

Functions of Components

Pre-shredder

Shred the scrap wires into small segments, making them more suitable for the subsequent crushing.

Crusher

It is responsible for crushing small segments into mixed particles of copper and plastic.

Dust collection

Handle the dust generated during the process of crushing wires and improve the purity of copper.

Conveyor belt

Carry and convey scrap wires and cables for subsequent processing and handling.

Vibrating table

It has two layers, and its main purpose is to achieve effective separation of copper and plastic through vibration and screening.

Airflow separator

Separate copper granules and plastic granules based on their weight difference.

Magnetic separator

Absorb the iron contained in copper granules during production process, and reduce the wear of the copper granulator machine blades.

Electrostatic separator

Separate copper and plastic particles by taking advantage of the difference in conductivity between copper and plastic.

D series copper granulator machine

D series copper granulator machines are extremely cost-effective. They have low machine prices and operational costs, designed to help you gain profits while minimizing your costs. Although they have a smaller processing capacity, they can still process a wide range of scrap wires and have the same high quality and excellent performance as the larger machines. Our D series copper granulator machines are definately worth far more than their price tag.

N series copper granulator machine

We designed our N series copper granulator machines with efficiency and performance in mind. This series of machines is primarily targeted towards customers with large amounts of scrap wires. They have ultra-high processing capacity, support efficient processing of scrap wires, and can maintain stable working performance during long-term operation. If you are interested in our N series copper granulator machine, you can click on the link to learn more about the machine details.

Sorry, we couldn't find any posts. Please try a different search.

The advantages of our copper granulator machine

High efficiency

Our copper granulator machine adopts advanced crushing and separation technology, and equips with an automated control system to achieve one-button operation, greatly improving recycling efficiency and production efficiency.

High economic benefits

The use of copper granulator machine can extract copper and plastic resources from scrap wires. The purity of copper and plastic after extraction can reach 100%, bringing considerable economic benefits to the enterprise.

Wide range of applications

We have many models of copper granulator machines. Different models have different processing capacities and processed cable diameters to meet your diverse production needs.

Low costs

We use advanced energy-saving technology to effectively reduce the energy consumption of copper granulator machines, which can reduce operating costs and quickly obtain profits.

Automatic stripper machine

Automatic stripper machine is a kind of recycling mechanical equipment, which is used to efficiently and accurately remove the outer insulation material of scrap wires and cables, and recover the metal core inside.

Structures of stripper machine

Our automatic stripper machine mainly including adjust handle, entrance hole, blade, two blade shafts and two rollers.

Functions of components

Adjust handle

It includes wheel adjuster and blade adjuster. The wheel adjuster adjusts the gap between wheels, the blade adjuster adjusts the gap between blades.

Entrance hole

Feed the cable into the roller, so as to drive the roller to rotate and make the cable move forward.

Blade

The blades of the wire stripper machine are mainly used for stripping and cutting the insulation layer of the wires.

Blade shaft

Image Accordion Content Goes Here! Click edit button to change this text.

Roller

Transport scrap wire and cables and stripped wire ends.

Stripping series Automatic stripper machine

For wire and cable recycling machines, a small wire stripper machine is the best and fastest way for the cables which is suitable for stripper machine, the stripped copper wire also can be sold at a good price. We have various types of wire stripper machines, from small strippers (suitable for wire diameters under 72MM) to big wire stripper machines (suitable for wire diameters above 120MM to 200MM or customized diameter range), for any questions, you can contact our staff, our experienced staff will give you the best solutions.

The advantages of our stripper machine

Improve production efficiency and output

Our wire stripper machine can achieve fully automated operation, greatly improving production efficiency and output. It can complete a large number of wire stripping operations in a short time, effectively saving labor and time costs.

Guarantee economic profits

Our machines adopt a precise cutting system, which can accurately strip the insulation layer of the wire, ensuring the purity of the metal core, thus guaranteeing good economic benefits.

Versatility

Our wire stripper machines can be adjusted according to different wire specifications and requirements, suitable for various types of wire stripping operations. This versatility makes it highly applicable and competitive in the market.

High cost performance

The price of our machine is relatively low, which is more economical than hiring multiple workers. At the same time, the wire stripping machine has a long service life and can be used for many years with proper maintenance.

get your best price today.

You can compare different models of machines on the website and make a decision. If necessary, you can contact us and we will help you.

The difference between copper granulator machine and wire stripper machine

The copper granulator machine crushes scrap wires and cables into particles through mechanical crushing to separate the plastic and copper. It is suitable for processing various miscellaneous wires.

While, the wire stripper machine uses a blade to cut the insulation layer, thus recycling metal core of the wire, which is suitable for stripping wires with thicker diameters.

You Can Also Click The Right Link To Get More Information About Their Difference

Cable Granulator and Copper Wire Stripping Machine, Which One Is More Suitable for You?

Ⅰ. Introduction Cables are widely used in various applications wherever electricity exists, therefore, there are huge amounts of waste cables generated everywhere in the world.

Difference Name | Copper Granulator Machine | Wire Stripper Machine |

Working Principle | Crush The Wire Into Copper And Plastic Granules | Strip The Wire Insulating Layer |

Processing Cables Type | Network Wire, Car Wire, Capillary Wire, Communication Wire, etc. | Armored Wire, High Density Wire, Multi-core Wire,etc. |

Application Scenario | Waste Recycling Stations, Metal Processing Plants, Automotive Industry, Cable Manufacturers, etc. | Wire Production, Electronic Products, Building Electrical Wiring, Scrap Cable Recycling, etc. |

What We Do

Manufacture and Supply

We specialize in manufacturing and supplying wire and cable recycle machines with various capacities and features.

We focus on incorporating advanced technology into our wire and cable recycle machines to enhance their efficiency and performance.

Our customer service includes installation, operational training, and maintenance support for our wire and cable recycling machinery.

Why Choose Us?

Choose us for our expertise in wire and cable recycling machines, reliable technology, and commitment to customer satisfaction and technical support.

Effective Team Work

Our team’s effective collaboration enhances productivity and innovation in manufacturing wire and cable recycle machines.

25+ Years Experience

With 20 years of expertise, our company specializes in manufacturing wire and cable recycling machines, offering reliable and advanced solutions.

High Technology Factory

Our high-tech factory focuses on the production of wire and cable recycle machines using innovative technological methods and efficient production systems.

Flexible Payment Plan

Our flexible payment plans for wire and cable recycle machines accommodate various budgets, ensuring accessible and manageable financing options for customers.

Smile Customer: Trust you will be same with our customer

How to Get wire and cable recycle machine from us

For more information about buying a wire and cable recycle machine from us, please contact our sales team, specify your needs, and select a suitable payment option.

01.

Inquiry and Consultation

Contact us for inquiries about our products, our team provides expert consultations to meet your specific needs effectively.

02.

Customization and Quotation

On inquiry, you will receive personalized solutions and a detailed quote for your specific wire and cable recycling machine needs.

03.

Order Confirmation and Manufacturing

We start accurate manufacturing after receiving order confirmation, ensuring timely production and compliance with specified quality standards for each unit.

04.

Delivery and After-Sales Support

Our delivery service ensures prompt and secure transport of products. Machines are also backed by comprehensive after-sales support for troubleshooting and maintenance.

FAQs

Copper cable and wire recycling machines are known for their ability to recover copper at very high purity levels, often exceeding 99%. This high purity is crucial for ensuring that the recycled copper meets industry standards and is suitable for use in various applications, including electrical wiring and manufacturing.

The capacity of copper cable and wire recycling machines varies significantly based on the model and design. We can provide you from 40KG/H to 2T/H. Smaller machines might process a few hundred kilograms per hour, suitable for small-scale operations, while larger, industrial-grade machines can process multiple tons per hour, catering to larger recycling facilities.

After-sales support typically includes installation assistance, operational training, and regular maintenance services from BSGH Granulator. Additionally, we usually offer technical support and a supply of spare parts to ensure the machine’s longevity and consistent performance. Some may also offer troubleshooting and repair services to address any operational issues that arise.

Yes, copper cable and wire recycling machines are designed to accommodate a wide range of wire sizes and types. They can process everything from fine wires in electronic devices to thicker, insulated power cables. Adjustments can be made to handle different wire diameters and insulation types effectively.

The lifespan varies based on usage intensity and maintenance, but typically, a well-maintained machine can last for more than 10 years. Regular maintenance and timely replacement of wear parts like blades and screens are crucial for prolonging the machine’s life.

Lets Tell Us About Your granulator machine Needs

Let us know your specific requirements for a wire granulator machine. Based on your needs, we will develop processing solutions designed to enhance the efficiency and performance of your recycling process.

- Whatsapp/Viber: 008613772508206

- Email: coppergranulator@bsghrecycling.com

- Website: https://bsghgranulator.com/