We Have A Promotion

China Double 11 Shopping Festival is coming, this is the only promotion of the year. In order to thank customers for their support and to allow more users to buy higher quality copper wire granulator with a more affordable price, BSGH Granulator has launched a copper wire granulator promotion. All D-series copper wire granulators are included in this promotion, with discounts ranging from USD 100 to USD 500.

After our promotion was launched, many customers sent inquiries and wanted to buy our machines. On October 5, a regular customer from Argentina purchased 1 BS-D65 copper wire granulators and 2 BS-D30 copper wire granulators from us.

Transaction Details

Our Argentine customer is a very strong local dealer with a wide range of product lines. He not only sells copper wire granulators, but also motor recycling machines and other equipment.

Two years ago, he purchased a total of 2 D75 copper wire granulators and 1 BS-S10 copper wire granulator from our company and found that local novices liked these two machines very much. After using our copper wire granulator, his customers earned back the cost of the machine within half to one month and made additional profits. Now his customers have expanded their production scale. The previous small copper wire granulators can no longer meet his customers’ current production needs, so they want to buy larger copper wire granulators from him now.

After learning about our promotion, our Argentine customer immediately contacted us and told us that he wanted to buy copper wire granulators with more powerful performance and larger processing capacity. Therefore, we recommended the high-performance BS-D30 and the BS-D65 electrostatic separator copper wire granulator to him.

Machine Feature

BS-D30 Copper Wire Granulator

BS-D30 has the largest processing capacity among our small copper wire granulators. It has a compact structure, and simple operation, and its processing capacity can reach 300kg/h. BS-D30 uses a national standard pure copper motor with better conductivity and durability and can ensure stable output capacity under high-load scenarios. At the same time, the blade uses a high-end imported SKD-11 high-chromium alloy, which has good wear resistance and impact resistance. Whether it is thin or thick wire, it can be fully crushed and has a long service life.

The video of the BS-D30 copper wire granulators working is shown below:

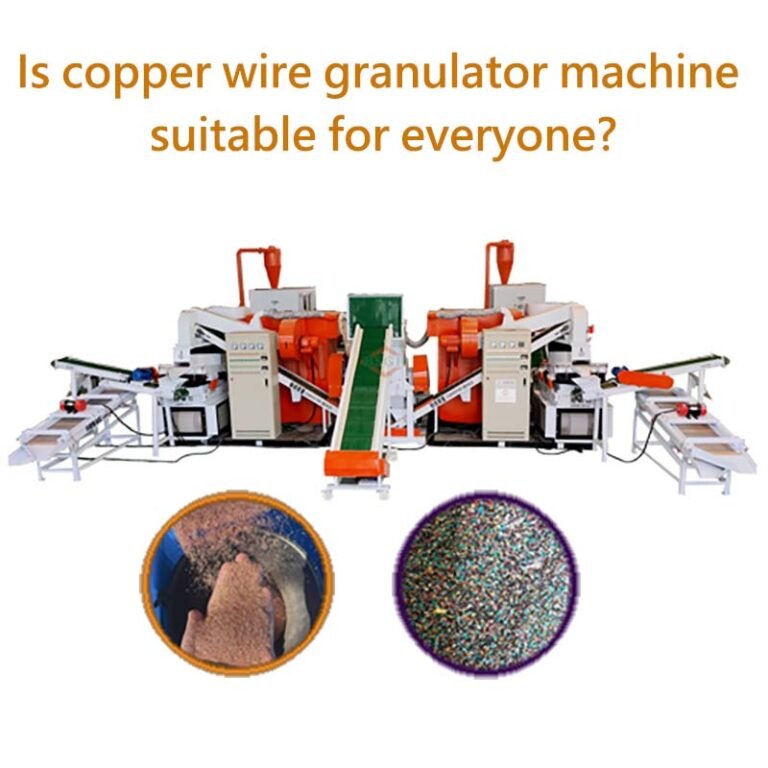

BS-D65 Copper Wire Granulator

BS-D65 is specially designed for customers who need to process more fine wires. This machine is equipped with a larger feed port and blades, and it is assembled with an electrostatic separator so that you can get 100% pure copper. The processing capacity of BS-D65 reaches 300-500kg/h, and it is the most cost-effective all-round medium-sized copper wire granulator.

The video of the BS-D65 copper wire granulators working is shown below:

Package And Delivery

After learning about the introduction of these two machines, our Argentinian customer was very excited and immediately placed an order for 1 set of BS-D65 copper wire granulators and 2 sets of BS-D30 copper wire granulators, because the voltage are same as domestic. Hence, we sped up the production for our customer and will let his customer can get the machine before Christmas, so after these machines’ production finished, we sent the customer trial videos of the machines. After confirming that it was running well, we began to arrange shipment for him.

Our rapid production capacity allows us to meet diverse customer needs effectively. With modern facilities and a skilled team, we can quickly scale operations for timely delivery without compromising quality. Whether you need custom solutions or large orders, our flexibility and responsiveness make us a trusted industry partner

About US

BSGH Granulator was established in 1995 and has a history of more than 25 years. We mainly produce copper wire granulators, wire stripping machines, motor recycling machines, radiator recycling machines and other mechanical equipment. Our machines are suitable for both dealers and individual recyclers. In order to win the praise of every customer, our product R&D department, manufacturing department and after-sales team work together to protect the recycling business of all customers. Whether it is machine selection or after-sales problems, we can provide you with professional solutions.

If you want to ask for personal recommendation, please don’t hesitate to contact us!

- Email: coppergranulator@coppergranulator

- WeChat/Whatsapp/Viber: +86 13772508206

- Website: www.bsghgranulator.com