Brief Introduction of all our machines

Our goal is to produce all kinds of machines involved in the scrap metal recycling industry. Take the scrap metal recycling process as a timeline to see what kind of machines BSGH Granulator has. We manufacture a lot of machines with their own recycling aims:

- Hydraulic alligator shear cuts large objects into smaller pieces to make the next recycling easier.

- Different types of recycling machines with various capacities which are designed to separate copper from waste wires, motors and radiators.

- The metal balers will make subsequent storage and transportation easier.

- Hydraulic briquetting machine is convenient for smelting into furnace which is important for reuse. It is clear to see that we can provide products for the entire scrap metal recycling industry needed which means any practitioner in this field can find the machines they want here.

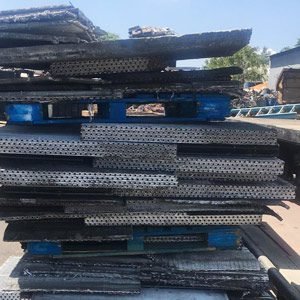

Hydraulic alligator shear

Which kind of materials can be cut by hydraulic alligator shear?

As its name suggests, alligator shear is just like a pair of powerful large scissors that can be used to cut large pieces of scrap metal in a cold state. It is good at cutting different structures like cans, pipes, plate and so on. Various metals such as copper, aluminum, iron, tin are within the processing scope of alligator shear. Car pieces are also suitable for alligator shear which can be cut into square pieces of different sizes.

What makes our hydraulic alligator shear unique?

The most prominent features of alligator shear are safety and convenience. It can reduce at least 7-9 manual workloads improving work efficiency while avoiding manual safety concerns.

1. Alligator shear is made with a strong structure and good wear resistance. Its blade base has an outstanding bearing capacity.

2. The powerful hydraulic cylinder greatly enhances the cutting force and processes the hard metal effortlessly.

3. During the operation process, every part of the blade exerts good force making the cutting complete.

Copper recycling machine

What is copper recycling machine?

Copper is highly valued in the scrap metal recycling industry. Waste cables, radiators, and motors all contain copper, but their structures are different, so they need to be recycled with different machines. Because customers have various quantities of raw materials, therefore each machine is subdivided into many models with different processing volumes.

For waste cables

Overall introduction

Cooper wire stripper machine and copper wire granulator machine are designed to separate copper from waste wires with a diameter under 25mm better. If you want to process scrap wires below 2mm, you can add the electrostatic separator to help.

Which one is most suitable for me?

In theory, both of them can handle wires larger than 2 mm in diameter. However, considering the processing effect and the long-term use, copper wire stripper machine is more suitable for wires with a diameter larger than 25 mm. The copper wire granulator machine is designed for processing all kinds of mixed cables, miscellany cables and thin cables wire stripper machine can’t process. For thin cables with a diameter of under 25 mm, a copper wire granulator machine is the first choice. If you want to obtain a better separation effect, you can add an electrostatic separator as well.

For waste motors

Where can we find motors?

Motors are used in many places in people’s production and life, such as fans, cars, cranes and some large machines in factories. In order to recycle the copper from them, we have developed various types of motor wrecker machines.

Can all kinds of motors be recycled with one machine?

The answer is no. The structures of motors are not the same, so it is impossible to recycle all of them with just one machine. To cater to the diverse needs of all customers, we now have motor wrecker machine which is capable of processing motor stators, compressors, car alternators and electric vehicle rear wheel motors, common industrial motors, new energy motors and so on, all in all, you must can find one fit for your demands from our company.

For waste radiators

Radiators may be used in household appliances such as air conditioners, cars, heaters, and refrigerators. As people’s living standards improve, these home appliances are used more and more frequently resulting in many scrapped raw materials. Therefore, we create radiator recycling machines to recycle copper from waste radiators. We also produce related products- band saws -to cut the thickness and width of the radiator to a size that can be processed by the radiator stripper machine.

Metal baler machine

It can extrude various metal chips of steel, iron, copper, and aluminum into qualified furnace material with different shape which is easy to store, transport, and recycle. Waste metal will be cold-pressed directly and the entire production process does not require heating or adding additives which ensures that the original material remains unchanged during the compression and can be sold at a great price. We have lots of metal baler machines with good quality and the processing capacity is not the same surely satisfy the requirements of customers from all around the world.

Hydraulic briquetting machine

BSGH Granulator Hydraulic Briquetting Machine is used to mainly briquette all kinds of metal turnings back into the furnace to reuse original scrap metal. The entire process does not require heating, additives, or other processes to facilitate storage and transportation and reduce losses during subsequent burning and recycling. The briquette machine can not only process copper scraps, but also aluminum scraps, scrap steel, iron scraps, etc., so the machine is suitable for metal profile factories and metal foundries, and other related enterprises.

Conclusion

As you can see, we have the most comprehensive range of machines in the recycling industry. No matter what do you want to recycle, you can consult us, We have been developing in this industry for more than 25 years which means each machine has passed the test of the market and has a mature technology. Welcome to cooperating with us!