Increasing concern for environmental sustainability, how electric wires are handled has never been more crucial. Choosing a suitable copper wire recycling solution can directly affect your profits, the invested costs and the Security of investment income of your business. BSGH provides a comprehensive recycling solution with two types of copper wire recycling machines: copper wire stripping machines and copper wire granulator machines. Each type includes various options suitable for recycling all types of electrical wires. This article will delve into these two machines in detail to assist you in making a wise decision.

Ultimate Guide for Copper Wire Recycling Solutions

Copper Wire Stripper Machine:

Electric wires are composed of conductive metals such as copper and aluminum, covered by insulating materials to prevent shocks. These wires come in diverse types and sizes, each tailored for specific tasks. Their applications are in various industries, from powering our homes and appliances to driving manufacturing processes and global communication networks. BSGH offer various medium and big copper wire stripper machine for thick copper wires. our machines have various stripping hole configurations and different designs and power.

| Item | Range(MM) | Hotsale | Representative |

| Large | 2~200 | BS-200/AC120/AN120 BS-4 | BS-AC120 |

| Medium | 2~72 | BS-AC55/AC50/AC80/KOF/KOA | BS-AC80 |

| Small | 2~40 | BS-015M/002/009 | BS-015M |

Is It Worth Stripping Copper Wire?

Copper wire recycling brings economic and environmental advantages, which is widely acknowledged. The question many individuals and businesses face is whether the effort and time required for stripping copper wire are worth the returns. To answer this, we’ll explore the value of recycled copper and the factors that contribute to the worth of stripping scrap copper wire.

Understanding the Value of Recycled Copper:

Copper has considerable value thanks to its versatility and vital role in industries, Known for excellent conductivity and corrosion resistance, copper is widely used in various industries, including electrical wiring, plumbing, electronics, etc. The value of recycled copper is reflected in reducing new copper extraction, market value varies with global supply and demand.

Factors Influencing the Worth of Stripping Copper Wire:

- Copper Content:

A wire’s value is mainly determined by its copper content. Thicker wires with a higher copper ratio yield better returns.

- Efficiency of Stripping:

Wire stripping is crucial for small-scale recycling, the process is quite simple, often achievable with a sharp knife. However, if you want speed and precision, an automatic wire stripping machine can highly enhance efficiency and reduce labor time.

- Quantity:

Choose a method based on the quantity of wire you have: for small quantities, a stripper machine is recommended; for larger quantities, a granulator machine is optimal. The right way can help you get more time and profits.

Cables types suitable for stripping:

For diameters above 20mm, we recommend customer peel directly and the inner small copper wire is processed by BSGHgranulator. Cables such as armored cables, submarine cables such kind, must be stripped and worth to strip more.

Case Studies:

- Copper Price:

As of the last update in 2023, copper prices were on an upward trend due to increasing demand in electronics and renewable energy industries.

- Case Study – Small Scale Recycling:

An analysis conducted by a recycling center showed that stripping copper wires yielded a return of approximately $2 to $3 per pound, whereas unstripped wires only returned around $1 per pound.

- Case Study – Industrial Recycling:

Big scale for dealing with tons of larger scrap copper wire yields higher profits when the wires are efficiently stripped using specialized machines. While the value of stripping scrap copper wire depends on cable types and the efficiency of the recycling method, data and case studies indicate that it is indeed worthwhile.

Easy Way to Strip Copper Wire for Recycling

How to peel copper wire fast? The proper use of copper wire stripping machine can greatly enhance efficiency. Here are some effective steps for using copper wire stripping machine:

1: Preparation and Safety:

Before starting, ensure that the copper wire stripping machine is in good condition and lay on a flat surface.

Wear appropriate safety guards to protect yourself from any potential hazards.

2: Sort and Organize:

Separate your electrical wires by type and size. Different wires may require different settings on the stripping machine.

3: Adjust:

Adjust the handle to set for different wire sizes. Make sure to adjust machine to the appropriate gauge for the wires you’re working with.

4: Feed the Wires:

Feed the wires into the machine’s input area based on different diameter ranges. Some machines have guides or channels to help align the wires properly.

5: Begin Stripping:

Start the machine as per the manufacturer’s instructions, input the cable and machine will automatically strip the wire.

6: Monitor the Process:

Keep an eye on the stripped wires as they come out of the machine. Make sure that the stripping process is clean and smooth.

7: Collection:

Gather the stripped wires as they come out of the machine. You can place a container or bin nearby to collect the stripped wires.

8: Inspect and Store:

For some stripped cables, you need to manually peel off the plastic and then Store the stripped wires ready for further use.

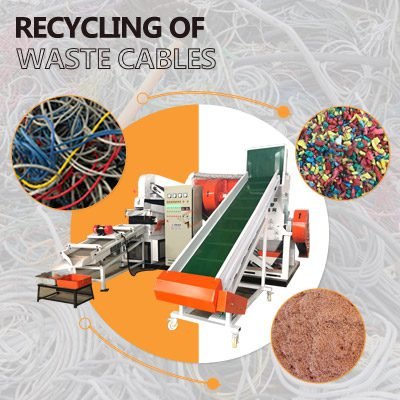

Copper Wire Granulator Machine:

When it comes to copper wire Granulator machines, we usually think about dry granulator recycling. It’s the most popular choice due to its super performance and environmentally friendly design. Different from the copper wire stripping machine, the copper wire granulator machine is a type of machine that operates through shredding and separation. These machines enhance your working efficiency and are more versatile than merely stripping wires.

Which kinds of Copper Wire granulators does BSGH have?

BSGH provides a wide range of granulators, catering to various capacities ranging from over 2 tons per hour to a minimum capacity of 70 kg per hour for industrial use. BSGH granulator includes large, medium and small types, ensuring we can meet your specific requirements. Here are some of our best-selling models for your reference.

| Hotsale Model | Capacity | Power |

| BS-F3000 | 1200~1500KG/H | About 125KW |

| BS-N130 | 400~700KG/H | 67KW |

| BS-N125 | 300~500KG/H | About 45KW |

| BS-D60 | 300~500KG/H | 48KW |

| BS-D75 | 70KG/H | 18KW |

Features of Copper Wire Granulator Machine

The copper wire granulator machine stands out as a versatile and efficient tool for recycling copper wires and cables, here are some key features that make the copper wire granulator machine a valuable asset in the realm of wire recycling:

Shredding & Granulation:

The machine is equipped with a powerful shredder that shreds the entire copper wires and cables into smaller pcs. This granulation process is a crucial step in preparing the wires for efficient recycling.

Multi Separation:

BSGH copper wire granulator machine incorporates airflow separation, vibration and magnetic separation for multi-stage separation processes. This combination ensures a maximum recovery rate and effectively separates copper from insulation materials.

Automation:

Copper Wire Granulator Machines are designed for automatic processing, reducing labor and streamlining the recycling process. This automation leads to improved productivity and efficiency.

Versatility:

The machine is designed to handle a wide variety of copper wires and cables, including insulated wires, slim cables and mixed wires, etc. This versatility accommodates different wire recycling needs, comes in various sizes and capacities, allowing for the processing of both small-scale and large-scale wire recycling operations.

Special Type: Wet Copper Wire Crushing Machine

A wet granulator machine is a machine that crushes copper wire scrap and separates the copper from the plastic by using water and vibration. Water recycling methods are rarely used nowadays due to water waste and pollution. However, certain types of waste electric wires only can be effectively recycled by wet granulator machine. This type of machine is much cheaper than the dry granulator, so still exists in some scrapyard. The wet copper cable wire recycling machine is especially effective for fine wires, jelly cables and oily cables.

The principle of water separation is as follows: By regulating the water volume to control the flow rate, underwater flow and the eccentric axis of the separation bed, heavier copper particles are directed towards the front discharge outlet, while lighter plastic particles are towards to the rear discharge outlet, copper and plastic can be separated efficiently.

Advantages:

cheaper price, dust-free operation and being the only machine capable of processing oil wires and jelly cables.

Disadvantages:

- Have secondary pollution of water and environment, many countries forbidden.

- The final product requires further steps, such as drying, which not only wastes time and labor but also has the potential risk of oxidizing the copper granules.

- Besides, when processing oil waste cables and jelly cables, the use of a degreaser and continuous stirring is essential. This adds complexity to the process.

- These factors make dry copper wire recycling machine the top choice in the recycling market because it effectively tackles these challenges with expertise.

How will you choose copper Wire Stripping Machine and Copper Wire Granulator Machine? The difference as follows:

Copper wire stripping machines and copper wire granulator machines are the main equipment in the field of wire recycling, they serve different purposes and have distinct functions. Here, we’ll explore the key differences between these two machines:

| Item | Copper Wire Stripping Machine | Copper Wire Granulator Machine |

| Function | Stripping copper wire you can get complete copper and plastic | Shredding and crushing you can get pure copper granules and plastic granules |

| Processing Capacity | Suitable for smaller quantities of wires. | Suitable for big quantities of wires. |

| Wire Type | Fit for tidy copper wire | All kinds of wires, including complex wire, mixed cable and slim cables |

| Automation | By stripping copper wire you can get complete copper and plastic | Automatically crush and separate copper and plastic particles |

Choose the Suitable Equipment for Dealing with Different Wires:

Choosing the right electric wire recycling solutions can contribute to waste reduction, conservation of valuable resources, and the reduction of environmental impact from discarded wires. Whether you’re working with thin copper wires or larger cables, BSGH offers suitable equipment options to help you achieve your recycling objectives.

In fact, the Automatic Copper Wire Stripping Machine is best suited for efficiently removing insulation from bigger diameter wires and on a smaller scale, while the Copper Wire Granulator Machine is fit for smaller and more complex wires and processing larger quantities of copper wires. The choice between these two machines depends on the scale of your recycling needs, the desired output, and the type of wires you are working with. By selecting the most appropriate solution for your specific needs, you can get more profits and time.