copper wire machine

If you are looking for a copper granulator machine with low cost and high return, you can cooperate with us. Our copper wire machine’s cost performance will definitely far exceed your expectations.

Our machines are manufactured with precision and competence, capable of processing waste cables into pure copper and plastic particles, ensuring continuous output while minimizing downtime. They are world-renowned for their outstanding performance, high reliability, and longevity.

Best copper wire recycling solution

Copper wire machine has powerful processing capability, it can efficiently recycle almost all types of scrap cables and copper wires with a diameter of less than 25mm better, such as automotive cables, household cables, communication cables, etc., and can always maintain stable operation during long-term work. It is a secret weapon that helps you improve productivity and obtain long-term benefits.

You can choose one from our more than 60 copper wire machines, which are mainly divided into N series and D series. Whether you value performance or cost performance more, you can choose a model that satisfies you.

N Series Copper Wire Machine

N series copper wire machines are high-end products launched by BSGH Granulator, with excellent performance and super high recycling efficiency. Their quality not only represents the highest level of all BSGH Granulator machines but also occupies a leading position in copper recycling machines all over the world.

- Processing capacity range: 300KG/H~1500KG/H

- Some multifunctional models can handle radiators and small transformers.

- Their quality is comparable to any top copper granulator machine brand, and more competitive in price.

- Suitable for recyclers who have a lot of scrap cables and a stable cable source, and want a really high-quality machine.

D Series Copper Wire Machine

If the quantity of your waste cables cannot reach the processing capacity of the N series copper wire machine, or if you have a limited budget, then our D series copper wire machine may be more suitable for you.

The D series copper wire machines are popular all over the world due to their high-cost performance. They perfectly combine reasonable prices with excellent quality to provide recyclers with the most valuable waste cable recycling solutions, achieving a win-win situation of low cost and high return. Although their processing capacity is slightly lower than N series products, they also have excellent performance, which can ensure that the recycled copper is high-quality, impurity-free, and 100% pure copper.

- More than 40 models for you to choose

- Processing capacity ranging from 40KG/H to 1000KG/H

- Price range: USD4900~USD239900+

- All BSGH Granulator machines have passed CE certification.

get Beat price today.

Get the greatest deal for a copper wire machine today! We specialize in providing outstanding savings on top machinery. Our commitment to pricing ensures that you may take advantage of remarkable discounts without sacrificing performance. Don’t miss this chance to get the most competitive price on the market. Shop with us today to get the best deal for your wire processing needs.

Copper wire machine structure and function

Main Parts

Main crusher

The first step of the copper wire recycling system, it is mainly used to crush various scrap cables into 3~5mm copper and plastic mixed particles for subsequent recycling steps.

Air separator

The most important equipment in the separation system, uses wind and gravity to perform the first separation step for mixed particles.

Vibrating table

Vibrating table performs a second round of particle separation to thoroughly separate copper from plastic, this key component is especially effective, providing high-precision separation and enabling recycled copper reach 100% purity.

Dust collection system

Our copper wire machine uses the most advanced pulse dust collection equipment to collect all dust generated during the entire recycling process, ensuring that the machine meets global environmental standards.

Customizable options

To make our copper wire machine perfectly match the needs of all recyclers with different quantities and types of scrap cables, we have some auxiliary equipment for you to choose from, according to their different functions below you can choose some to configure to your granulator machine. If you need to process special types of cables, or if you have different requirements for the machine, please inform our staff in time and we will create the most perfect customized solution for you.

Blade material

Our main crusher blades are made of SKD-11 steel, with excellent hardness and wear resistance. It can achieve an ideal crushing effect and has high durability. If you have special requirements for the blades' material, we also support customization.

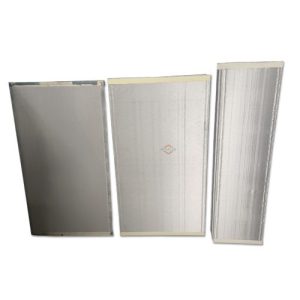

Screen size

The copper wire machine mainly has two screens. The crusher screen is mainly used to control the size of the crushed particles, and the air separator screen uses holes of different sizes to separate the crushed copper and plastic. We can flexibly customize both screens according to your raw materials and actual needs. In addition to the customization options mentioned above, we also support flexible customization of voltage, machine color, your company’s logo, etc.

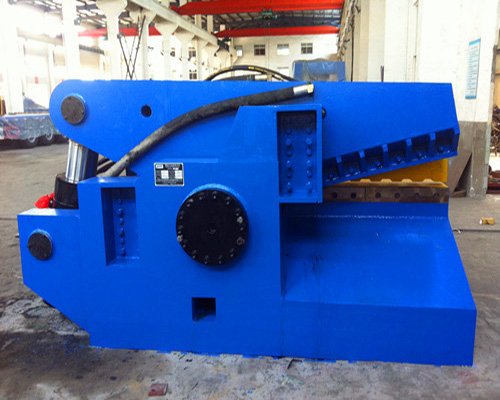

Pre-shredder

Add a pre-shredder to your copper wire machine. It can pre-process the waste cables into 5~25cm long strips before entering the main crusher, making the best preparation for subsequent recycling. The pre-shredder can not only increase machine’s processing capacity but also effectively protect main crusher blades and extend the service life of the copper wire recycling machine.

storage transfer device

The storage transfer device should be placed between the pre-shredder and the main crusher. It is mainly used to store pre-processed cables, has a large capacity, and can store 300~800kg of materials. At the same time, it can also automatically and evenly feed the pre-processed copper wires in the cabin into the main crusher for efficient processing, saving time and effort.

Conveyor Belt

Conveyor belt can convey the waste cables to each part of the machine, helping you simplify the operation step, realize fully automated production, and effectively reduce your labor costs.

Electrostatic separator

If you need to process a large number of very thin wires, we recommend that you purchase an electrostatic separator together with copper wire machine. The electrostatic separator can separate the plastic particles again before discharging, extracting the very light copper that the air separator cannot separate, effectively improving the copper recovery rate.

Magnetic Separator

Magnetic separator is a necessary equipment for processing iron-containing cables. It is designed to separate iron from all mixed particles to ensure that the final copper granules do not contain any iron particles.

Choose US your best choice

Advantages of our copper wire machine

In recent years, more and more copper granulator machines have appeared on the market. They look no different in appearance, but only those who have actually used them know that low-quality copper granulator machines not only have a high copper loss rate and waste a large amount of copper materials but are also accompanied by frequent failures and malfunctions that lead to long downtime and high maintenance costs.

BSGH Granulator is a high-end brand of copper wire machines, aiming to provide high-quality machines to support your recycling business. You can trust you’re investing in a copper wire machine with high efficiency, strong processing capacity, low cost, and high durability – these are also the key factors that make our machines stand out in the fiercely competitive market.

High durability

Every part of our machine is durable and can minimize wear and tear during operation. This allows our copper wire machine to have a service life of more than ten years with regular maintenance. By choosing it, your one-time investment can bring you long-term and stable returns.

High efficiency

Our copper wire machine can help you quickly improve recycling efficiency. Even if you choose the smallest model, it can quickly recycle 350-500KG of waste wires per day. Compared with similar machines on the market, our machine can process more raw materials in the same time and create more value for you.

Low costs

Copper wire machine can help you save costs in many ways. Firstly, it can be fully automated, one worker can operate the entire machine, saving you a lot of labor costs. Secondly, we adopt energy-saving design, low power consumption, and reduce your operating costs. Finally, the machine is made of high-quality steel, which solves the problem of frequent machine damage from the source, so you don’t have to pay extra repair costs.

Powerful processing capabilities

Whether copper wires or aluminum wires, high copper-content wires like communication cables, or low copper-content wires like miscellaneous wires, our machines can process all of them well. Moreover, by adding auxiliary equipment, you can also easily process iron-containing cables and very thin wires. Some large models can also help you recycle raw materials such as radiators, small transformers, etc.

Provide High quality Copper Wire Machine Machine for you

About BSGH Granulator

BSGH Granulator is the largest copper recycling machine manufacturer in China, with a market share of over 85%. We mainly provide a variety of top quality cable stripping machines, copper granulator machines, motor recycling machines, and radiator recycling machines.

We have been in the copper recycling industry for more than 25 years. Over the years, we have continued to innovate and create a variety of copper recycling machines with excellent performance and advanced technology. Our machines are sold to more than 80 countries and have been tested in the global market, each copper recycling machine is the best solution we have obtained by combining industry practices.

We reward every customer’s choice with the best machines and the most complete after-sales service. In the future, we are willing to establish friendly long-term cooperative relations with more domestic and foreign recyclers with the greatest sincerity to help them maximize their profits.

Quality assurance

BSGH Granulator has always considered quality as the most important factor in copper recycling machines. To ensure that every machine we sell meets the highest standards, we maintain strict quality control and provide comprehensive after-sales support.

1. Quality Assurance During Production

-

Raw material selection and inspection

High-quality raw materials are the basis of machine durability, BSGH Granulator is committed to using only premium materials to ensure that each machine is of top quality. All raw materials are carefully inspected before machine production, and no substandard materials will be put into production.

-

Precise manufacturing process and refined production management

We have set quality standards that far exceed the industry, and adopt refined production management during the production process to strictly control every detail of the machine. Our quality inspection team will conduct sampling inspections and records for each batch of blades, screens, and other accessories. Before assembling the machine, each part will be tested so that we can more accurately control the quality of each machine.

-

Fully functional testing of the final product

After machine production finishes, we will conduct multiple quality inspections and test runs, and send you a test run video. We will arrange shipping after you confirm the quality of the machine.

2. After-Sales Quality Assurance

-

Technical assistance and guidance

We provide detailed technical support, including machine usage, precautions, settings, calibration and troubleshooting methods, etc., to help you better use and maintain the machine.

-

Warranty and Service Commitment

We provide a one-year warranty. During the warranty period, any damaged part not caused by human factors can be repaired or replaced free of charge to ensure the machine's reliability.

-

Lifelong 24-hour online rapid response

Our machines generally do not malfunction under normal use, even if a malfunction occurs, our 24-hour online service team will do their best to help you solve it. If you have any questions during the use of the machine, you can contact us at any time.

Lets Work

How to Get copper machine from us

Contact us, select your desired copper wire machine model, and secure your order for hassle-free acquisition.

Inquiry and Consultation

Reach out to our experts to explore tailored solutions for your specific needs.

Customization and Quotation

Tailored solutions and competitive quotations to meet your unique copper wire machine requirements, ensuring optimal efficiency.

Order Confirmation and Manufacturing

Upon order confirmation and receipt of payment, we initiate the manufacturing process for your Cable Shredding Machine, adhering to strict quality standards and customization requirements.

Delivery and After-Sales Support

With our fast and efficient production system, you may receive order confirmation and start efficient manufacturing procedures.

Lets Tell Us About Your copper machine Needs

Tell us your wire granulator machine requirements, and we’ll tailor solutions to enhance recycling efficiency and performance.

- Whatsapp/Viber: 008613772508206

- Email: coppergranulator@bsghrecycling.com

- Website: https://bsghgranulator.com/