Introduction

Many customers, especially newers, feel confused during installation. They do not know where to start and how to install it efficiently and quickly. That’s because different brands of machines have their unique technical characteristics, so they need to be installed according to different requirements. The installation environment and detailed precautions also vary among different machines. This article takes the BSGH Granulator machine as an example to help customers understand how to install a copper wire granulator machine quickly.

Before Installation

Before installation, it’s essential to gather all the necessary tools and materials. Additionally, to choose a suitable location for the machine that offers adequate space and access to power sources, customers should understand related information from these four aspects: machine acceptance, environmental conditions required by the copper wire granulator, machine characteristics and worker training.

Machine Acceptance

Before installation, you should make sure the manufacturer has provided the necessary checklists and testing procedures before delivering it to you. After you receive the machine, a comprehensive inspection is necessary, you can check it through the following aspects: whether the number of machine parts is sufficient and whether there is any damage to them; Is there any defects on the machine such as bumps, cracks and deformation? When the above aspects are confirmed without any problems, you can proceed to the next step.

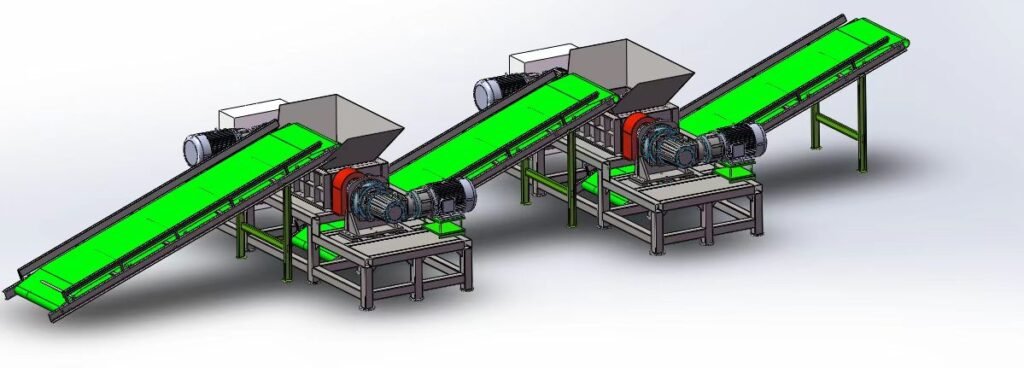

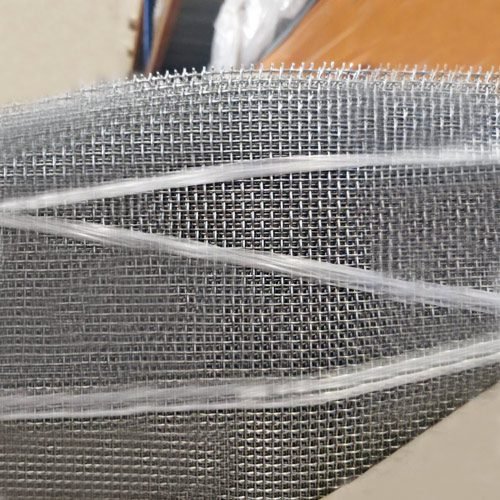

Here are some key parts of our granulators, like Blades, Shaft, and some customizable accessories like Pre-shredder, Magnetic Separator and Electrostatic Separator.

Environmental Conditions

Copper wire granulator machine generates heat during operation which is an adverse factor maybe increasing the rate of machine failure. Therefore, the machine-assembled water cooling system is especially good for Tropical places; It also generates dust so the optimal environment should be dust-free with a good ventilation condition in order to obey the local environmental protection regulations and protect the health of workers at the same time.

Machine Characteristics

The large copper wire granulator is truly something special – it’s not just about its high value or size, but it’s the really robustness of this machine that sets it apart. When you’re choosing the right one for your needs, it’s not just a decision; it’s like picking a partner for a life long journey, like valuable companion, it needs to be treated with care. No matter big or small granulators, you need to use forklift, to ensure that every inch of that granulator arrives safely.

Worker Training

Before installation, workers can learn the installation steps and precautions through the instructions we provided. We dive deep into those installation steps, breaking them down piece by piece. It’s not just about knowing what to do; it’s about understanding why we do it. And let me tell you, we leave no stone unturned when it comes to safety. We’re all about making sure our team knows the risks and how to handle them like pros.

Installation

After the machine arrives your factory, customers can begin to install it. Taking BSGH Granulator machines as an example, if it is installed based on the instruction, medium and small machines will take about 1hour, and large machines will take around 2 hour.

3 steps will help you to get the machine installed quickly, we list the specific installation procedures in the following.

1: Connect the machine correctly

Our machines are connected by assembly. Depending on the type, the specific installation sequence is different. Customers can install it in the order of the machine pictures.

2: Verify blades operating

Open the upper cover of the crusher and turn the cutter shaft of the crusher by hand to see if the rotation is smooth and whether the bottom screen is scratched.

3: Connect the power supply

Put the machine on a flat level floor, you must ensure the machine is on level or else will affect the machine’s performance.

Customers should insert a 1.5-meter iron bar into the ground and then use 6 square copper wires to connect the iron bar and the frame grounding bolt if your machine assembles with an electrostatic separator.

Then connect all the parts in an electric box and check all parts, and bolts are loosened or not, pls ensure all bolts are fastened tightly.

4: Machine inspection

Turn on the power switches of each device one by one and observe whether the motor rotation is right or not. You can also run it without any materials for half an hour to observe if there are any problems during the operation to ease the adjustment.

5: Adjust machine

After everything are ok, then running the machine, adjust the air bottom fan and air separator system vibration frequency till the machine reaches the best effect and the largest capacity.

After Installation

After the machine is installed and passes the test, it can be put into use. Reasonable maintenance methods are also very critical, you can learn more from them.

In conclusion, installing a BSGH granulator machine can be completed in just one hour to 2 hours with proper preparation and adherence to safety guidelines. And you can also refer to 25 Tips to make you succeed in copper wire granulator business