How To Recycle Scrapping Compressors?

I. Introduction If you walk into some scrapyard or appliance recycling center, you’ll see discarded compressors piled up, mainly from

The copper wire shredder BS-D10 is a high-performance machine and it can crush scrap cables at a speed of about 100KG/H and it can process a wide range of wires, such as car loom wires car harness wires, communication wires and so on. It is compact in size and easy to operate, which makes it popular in small copper recycling centers or scrapyards with limited space and manpower. Based on BSGH Granulator excellent producing technology, our BS-D10 copper shredder is so high-performance that you can get higher quality copper and earn more money with this machine.

The testing video shows us a well-running BS-D10 copper wire shredder machine, it is for our Indonesia client.

According to this video, we can find that the final copper we get is tiny and highly recycled from plastic, which can help us make more money because of its high purity. And we can also see that the machine works in a steady way.

According to customers’ feedback, it is hard to distinguish BS-D10, BS-D20 and BS-D30 copper shredder because of their similar appearance. So we compared these three machines here to help you choose. And the biggest capacity in these three machines is about 300KG/H, if you need bigger one, welcome to check our big capacity machines and medium capacity machines.

Machine Display

| Model | BS-D10 copper wire shredder | BS-D20 wire choppers machine | BS-D30 copper chopper |

| Capacity | 100KG/H | 200KG/H | 300KG/H |

| Size | 2230*1600*2000mm | 2600*1600*2000mm | 2700*2100*2300mm |

| Power | 24KW | 28KW | About 37.2 KW |

| Weight | 1800KG | About 2000KG | 3500KG |

| Configuration | The smallest feeding hole in three machine | midddle feeding hole in three machine | The biggest feeding hole in three machine |

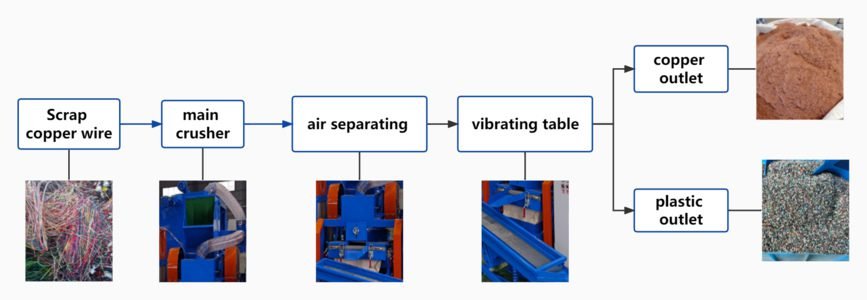

The process of using a copper wire shredder machine to recycle scrap cables typically involves several steps.

First, scrap cables are put into the feeding port of the machine and the blades in the main crusher will crush the scrap cables into smaller pieces.

Next, the crushed cables are transported to air separator, which separates the material into different components based on their density.

After processing by the air separator, the waste cable particles are further processed on a small vibration table, which helps to separate any remaining copper and plastic particles that may still be mixed together.

Finally, at the end of the recycling process, you will get pure copper and pure plastic, which are collected separately at the copper and plastic outlets, respectively.

As a small size machine, we pack BS-D10 copper shredder with plastic inside and plywood outside. And we will track package information until you recieve the machine.

Surely we can assemble a pre-shredder and conveyor belt for BS-D10, but we don't recommend adding it. Pre-shredder is mainly used for medium or bigger-size granulator machines. BS-D10 is a small capacity machine only 100kg/H, no need to add the pre-shredder.

No matter the big or small machine, dry recycling is better than water recycling.

The dry-type principal is by air and vibration separating, water type principal is by water cycle separating.

Yes, you can get pure products at one time. Our machine’s separation rate is up to 99.8%, so the final product is pure enough.

If you want to recycle completely, you need to assemble the electrostatic separator for thin wire.

Most customers choose our BS-D10 as the beginning of copper recycling business, if you are new in this field, I really recommend you this model for trying. In addition, we have prepared some articles to help you quickly know more about copper recycling industry, I believe these articles will help you a lot.

I. Introduction If you walk into some scrapyard or appliance recycling center, you’ll see discarded compressors piled up, mainly from

I. Introduction According to survey data, the number of photovoltaic modules is expected to reach 8 million tons by 2030.

It’s Our Great Honor To Serve You.

Send us a message if you have any questions or requests. Our experts will give you a reply within 1 hours and help you select the proper capacity machine you want.

008613772508206

coppergranulator@bsghrecycling.com

*All your information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe with us.

REPLY WITHIN 24HOURS.

Start growing with BSGH Granulator now, we can help you wholesale or use the machine at best effect.

Tks for your interesting for our machine, can you tell me more about your requests so i can recommend you the proper machine?

Online | Privacy policy

WhatsApp us

Which kinds of material you want to process?

Please fill in the following form(give us your specific requests, the detailed the better, so we can give you an optimal solution at the earliest time):

Maximize your recycling efficiency with our compact and powerful metal chip briquetting machines. Whether you’re dealing with small batches or large volumes of metal scrap, we have the perfect solution to fit your space and production needs.

Contact us today for a free, customized quote and discover how our briquette press can help you boost productivity and profits.

Ready to Turn End-of-Life Solar Panels into High-Value Treasure?

Whether you need a standalone Frame Dismantling Machine, a precision Glass Removal Machine, or a complete Solar Panel Recycling System—we have the right solution for your business.

Contact Us Today & Get a Free Quote tailored to your PV panels!

From robust tools to advanced recycling machinery, we provide a comprehensive selection: cutting, moving, shearing, grap, baler, separation, a series of heavy-duty equipment engineered to meet the demands of diverse industrial operations and material types. Which kinds of function do you need? Send us your requests now to let our machine help you to get more profits.

Please fill in the following form(tell us your requests or you can choose from):

| Home use wire stripper machine |

| 1.5MM-38MM; 2-45MM; 2-76MM; 2-60MM; |

| Industrial cable stripping machine |

| 10-120MM; 10-160MM; 60-200MM |

According to your requests, I’ll recommend the suitable machine.

We have all kinds of radiator recycling machines, besides single radiator stripper machines and radiator recycling lines, radiator cutting machines.

Our machines are capable of processing all kinds of scrap radiators, including car radiators, water tank radiators and AC radiators, aluminum-clad radiators etc.

Our metal baler can processing all types of scrap metals, besides light metal and heavy metals; ferrous metal and non-ferrous metals;

our machine have from small pressure to big pressure 80T, 125T, 135T, 160T, 200T, 250T,315T and 400T, if you not know which pressure should you choose, so please send us your material picture below and ask for a free quote now!

We have:

Can you tell me which kinds of material you want to process? click below and send material picture.

Process Motor Shell | Motor Stator | Motor Shaft

Motor Shell Cutting | Motor Stator Recycling

Auto Starter Cutting | Auto Starter Pressing | Car Starter Heating | Car Starter Pulling Machine

Car Alternator Cutting Machine | Car Alternator Pulling Machine

Motor Stator Recycling Line | Motor Rotor Recycling Line | Whole Motor Recycling Plant

For Small Transformer Recycling

Compressor Shell Cutting Machine | Compressor Stator Recycling

Mainly for Recycling Ceiling Fan Motors

For All Kinds of Car Magnetic Switch

For All Kinds of Electric Bike Hub Motors

Mainly for Press All Kinds of Motor Parts | Support Customized

1: Get copper price today FREELY!

2: Enter into scrap metal group FREELY!

3: Leave your information, get a cable cutter for FREE!

4: ROI Analysis for FREE!

5: Get extra one year warranty for FREE!

6: Get usd100 coupon for FREE!

7: Get spare parts for FREE!

8: Best seller of the month FREELY!

Note: Your email information will be kept strictly confidential.

Note: Your email information will be kept strictly confidential.

Please fill in the following form(tell us your requests or you can choose from):

| D Series Different Capacity |

| 50KG/H, 70KG/H, 100KG/H, 200KG/H, 300KG/H |

| N Series Different Capacity |

| 300~500KG/H, 400~600KG/H, 1T/H, 1200~1500KG/H |

According above different capacities, tell us your requests, once we get your detailed information for your requests, we will contact you at the first time with professional solutions and support from buying to using.